Dongshen's Breakthrough in Moulded Polystyrene Raw Material Project

Summary of EPS(Expandable PolyStyrene) raw material production

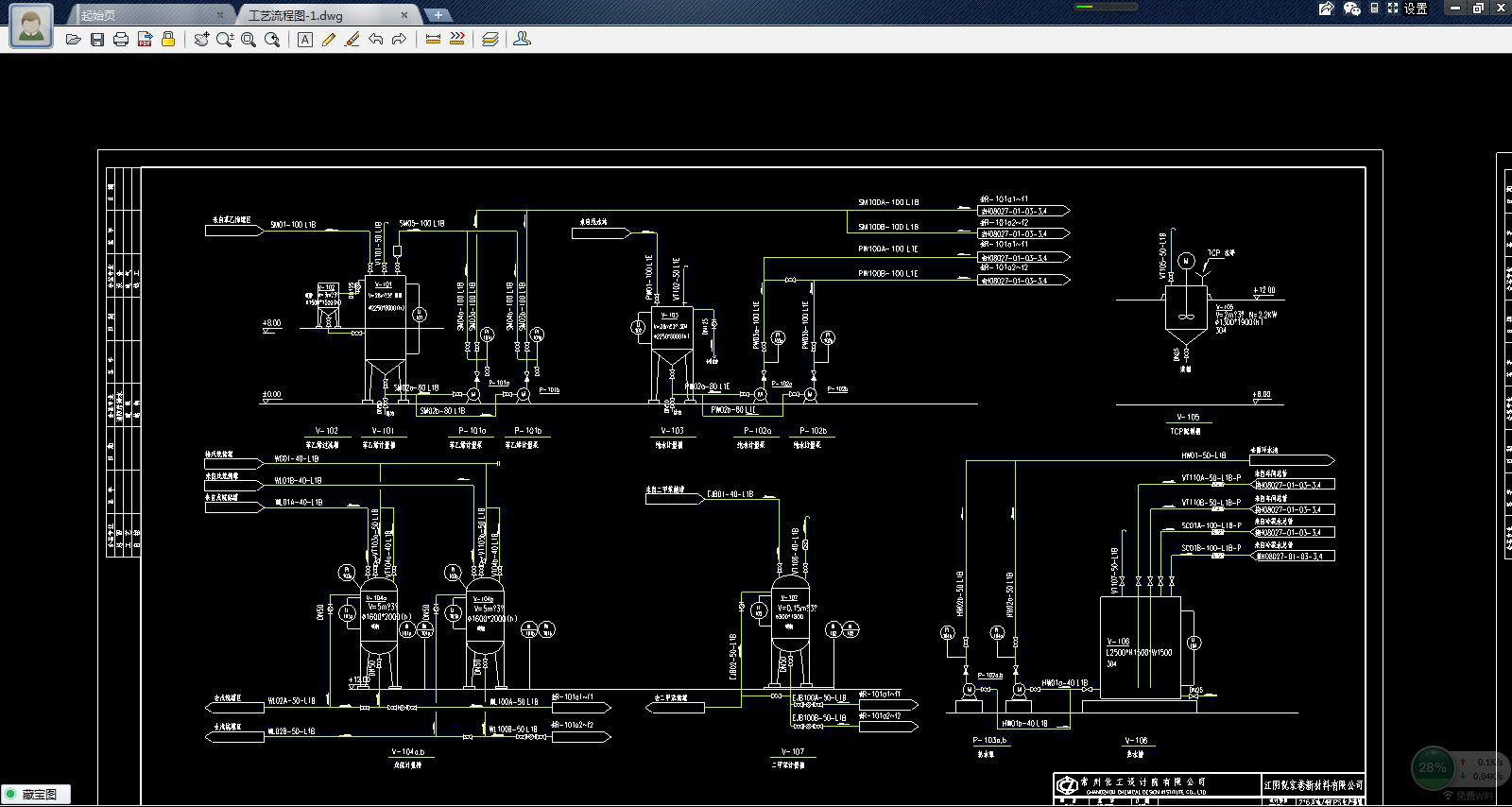

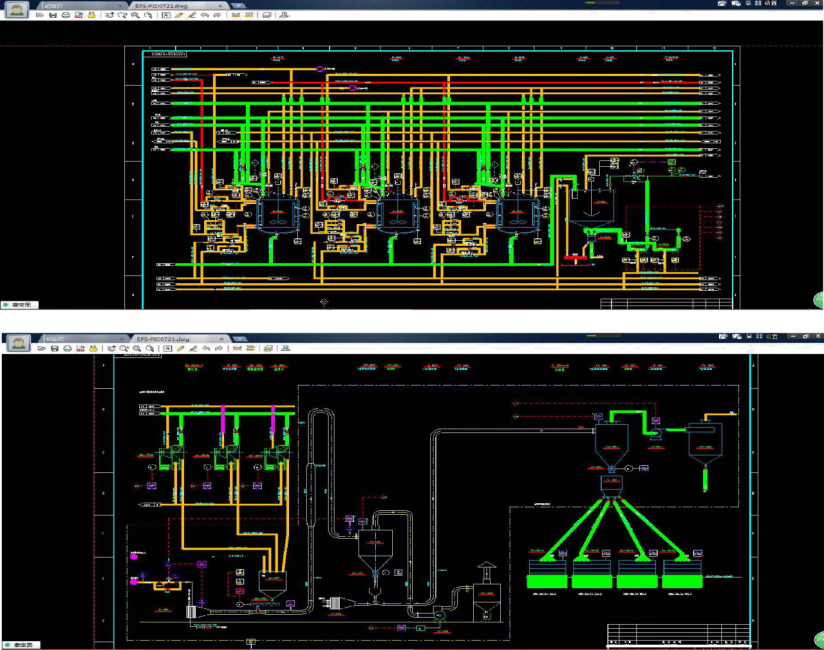

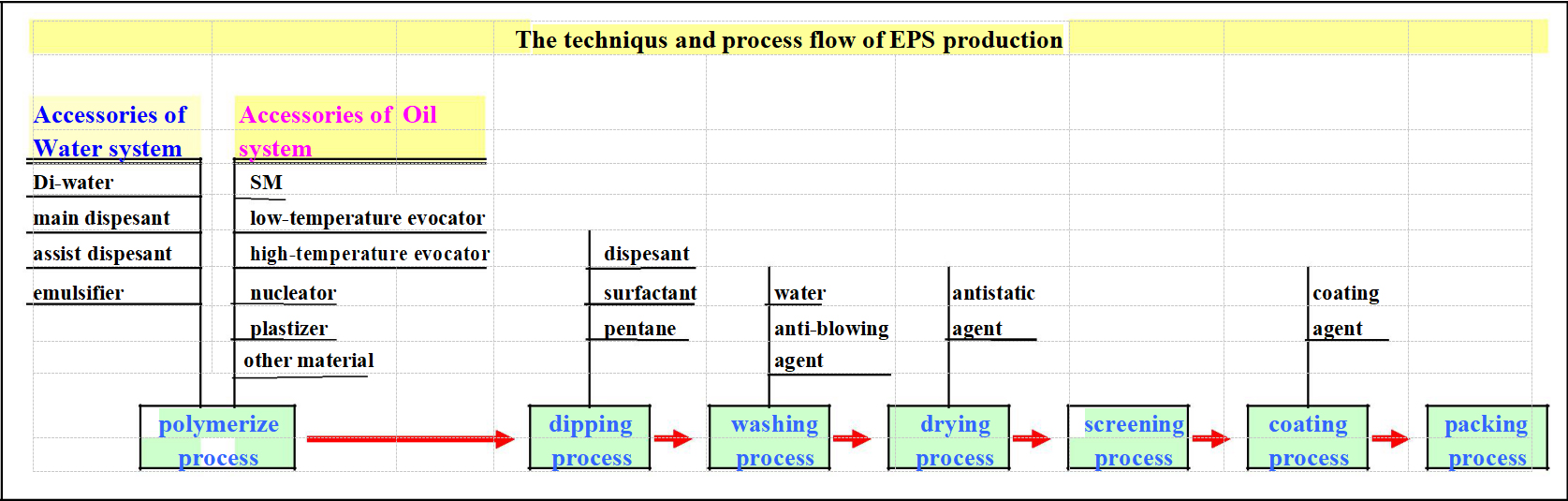

Process Flow introduction

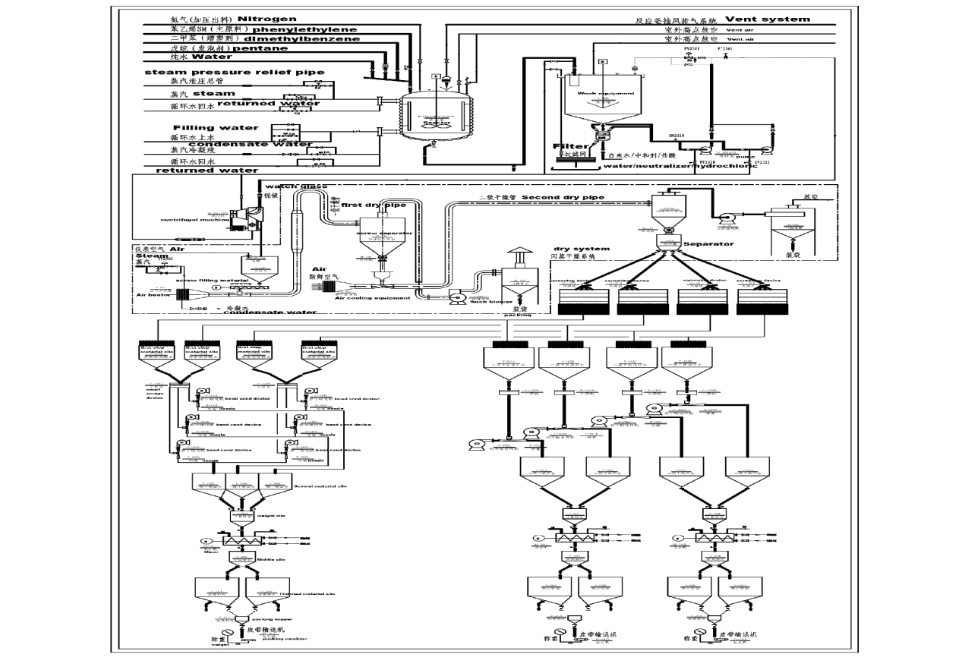

The process of one-step method including polymerization, impregantion, cooling, washing, drying, sieving, coating, vibration examation, packing. The average production cycle time of the EPS production is 16~17 hours.

(1) Polymerization and Impregnation

Polymerization and impregnation is proessed in the reactor. Under certain temperation, SM will polymerize. By comtinuous stiring, SM will be extended and cut into strips, then composing SM oil drops suspending in the water because of the surface pressure. There are dispersants suspending in the water to avoid SM particles bump and connect together. In this process the diserse power should be larger than the connect power to ensure the low-temperature polyerization.

The low-temperation polymerization reaction is running in the oil drop of SM, the heat released in the reaction will be taken away by the cooling water in the clip set. To remove the heat in time, we must ensure the normally work of recycling water system during reaction process. Otherwise, the temperature in the reactor will be too high, which lead to quick reaction and higher viscosity.

The beads production process is controlled manually, during the process, the temperature should be controlled proper to avoid large fluctuation, otherwise, the size range of beads will be widened. Meantime, frequently observation of samples is essential to control the size of beads.

By the adjust of light weight CaCO3 and TCP, the size of beads can be controlled.

DCS system is used for temperature control during the whole process of heating, polymerization, impregnation, high-temperature reaction, and cooling. To ensure safety production, the DCS system will control the reaction temperture and time, and alarm in over-temperature or overpressure case.

When the conversion rate of SM reach approximately 75%(about 4 to 5 hours under constant temperature), certain quantity of blowing agent should be added. After the impregnating and polymerization under certain time and pressure, we can get EPS beads.

The blowing agent for impregnation is injected into measuring kettle by pump, and accurately weighted by weighting device. After the high-tempterature process, when cooling to the specified temperature, the material can be discharged to washing tank.

(2) Washing

The impurities such as dispersant and defloculates must be removed by washing. After cleaning, the EPS beads will be dried by centrifugal dehydration to remove most surface water, and ready for further drying.

We can also use de-foaming agent to remove impurities.

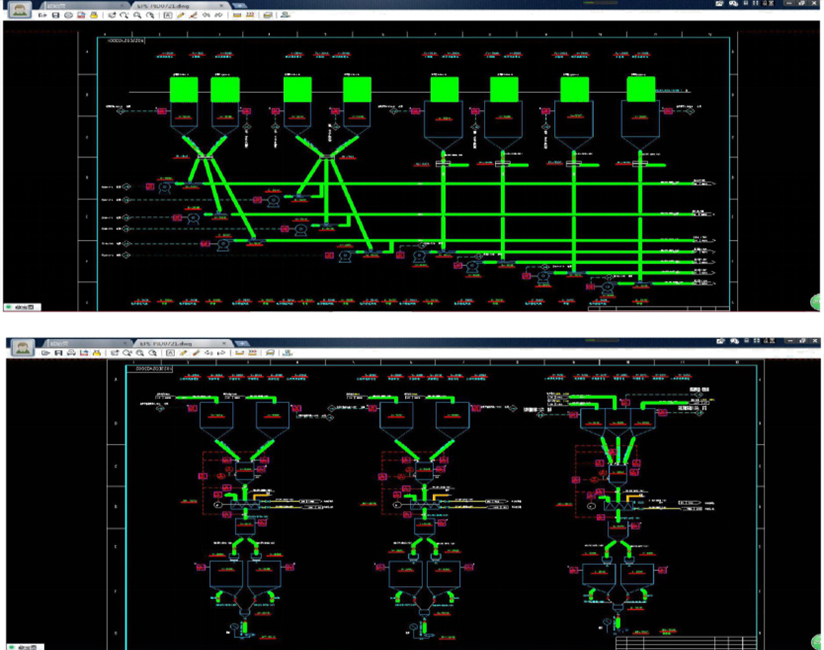

(3) Drying

After centrifugal dehydration, there would be about 3% water residue on the surface of EPS beads(highly water content will influence the quality of EPS products), so further drying process is needed, during this process, EPS beads are dried by hot air. Blowing by hot wind, the surface resident water become steam, then this kind of gas-solid mixture come into the diffusion type cyclone separator, while the beads fall to filter silo through outlet, the high-speed revolving airflow will form a low pressure area in the center of the separator, and push the hot humid air flow up through the center pipe. In this way the beads will be dried.

After hot air drying , the beads need to be cooled by cold wind to further reduce the water content, and get ready for the screening. To prevent the accumulation of electricity, antistatic agent should be added during drying.

The drying temperature is controlled by DCS system.

(4) Screening

The sizes of dried EPS beads are uneven, screening maching is needed to separate the beads by specification and transfer to different silos.

(5) Coating

During the EPS production, storage, transportation and process, the escaping of blowing agent is inevitable. If too much blowing agent lost, many problems will occurred, such as decrease of expanding rate, increase of density, difficulty of forming, etc. To extend the valid storage period of EPS, and prevent the loss of blowing agent, the use of coating agent at the surface of EPS is essential.

Case

Our vibration examination process evaluates the stability of the EPS beads, ensuring their suitability for packaging. Finally, the beads are packaged in a way that ensures their safe transportation and storage. Dongshen’s EPS Raw Material Project showcases our commitment to producing high-quality Moulded Polystyrene. By enhancing the process of production and refining our techniques, we aim to set new benchmarks in the Moulded Polystyrene industry.