Innovative Continuous EPS Pre-Expander: PB2000A-PB6000A Air Cooling EPS Block Molding Machine

Machine Introduction

EPS Block Molding Machine is used to make EPS blocks, then cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc.

EPS Air cooling block molding machine is suitable for small capacity request and low density blocks production, it’s economic EPS machine. With special technology, our Air Cooling Block Molding Machine can make 4g/l density blocks, block is straight and of good quality.

Machine completes with main body, control box, blower, weighing system etc.

Machine features

1. The machine adopts Mitsubishi PLC and Winview touch screen for automatic mould opening, mould closing, material filling, steaming, temperature keeping, air cooling, demoulding and ejecting.

2. Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

3. Mould cavity is made of special aluminum alloy plate with high-efficiency heat conduction, aluminum plate thickness 5mm, with Teflon coating for easy demoulding.

4. The machine set up high-pressure blower for suction material. Cooling is done by convection air by blower.

5. Machine plates are from high-quality steel profile, through heat treatment, strong and no deformation.

6. Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

Technical Parameter

Item | Unit | PB2000A | PB3000A | PB4000A | PB6000A | |

Mould Cavity Size | mm | 2040*1240*630 | 3060*1240*630 | 4080*1240*630 | 6100*1240*630 | |

Block Size | mm | 2000*1200*600 | 3000*1200*600 | 4000*1200*600 | 6000*1200*600 | |

Steam | Entry | Inch | DN80 | DN80 | DN100 | DN150 |

Consumption | Kg/cycle | 18~25 | 25~35 | 40~50 | 55~65 | |

Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | |

Compressed Air | Entry | Inch | DN40 | DN40 | DN50 | DN50 |

Consumption | m³/cycle | 1~1.2 | 1.2~1.6 | 1.6~2 | 2~2.2 | |

Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | |

Drainage | Steam Vent | Inch | DN100 | DN150 | DN150 | DN150 |

Capacity 15kg/m³ | Min/cycle | 4 | 5 | 7 | 8 | |

Connect Load/Power | Kw | 6 | 8 | 9.5 | 9.5 | |

Overall Dimension (L*H*W) | mm | 3800*2000*2100 | 5100*2300*2100 | 6100*2300*2200 | 8200*2500*3100 | |

Weight | Kg | 3500 | 5000 | 6500 | 9000 | |

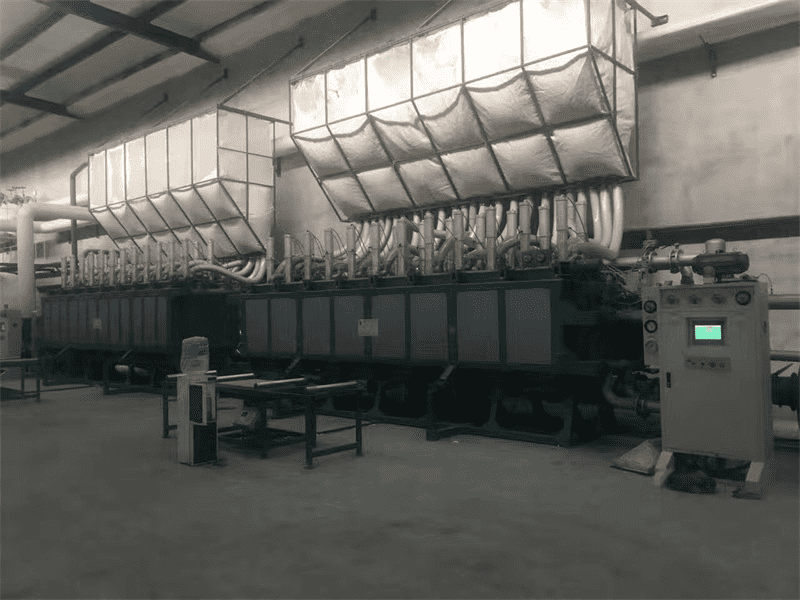

Case

Related video

The versatility of our Continuous EPS Pre-Expander is another major standout. It is designed to produce EPS blocks of varying sizes, thus ensuring it meets diverse needs. From generating insulation sheets for houses to providing packing solutions, the opportunities are endless. Moreover, the machine is also user-friendly, allowing for easy operation and maintenance. In conclusion, the PB2000A-PB6000A Air Cooling Type EPS Block Molding Machine is the game-changing tool you need for successful EPS block production. Experience efficiency, performance, and versatility like never before, as our Continuous EPS Pre-Expander takes your production process to an advanced level. Trust in DongShen, your reliable partner in delivering superior quality and innovation.