Eps Cutting Machine - Dongshen

Hangzhou Dongshen Machinery Engineering Co., Ltd, a leading manufacturer in the EPS industry, specializes in the engineering and production of high-quality EPS Foam Cutting Machines. With a strong emphasis on innovation and customer satisfaction, Dongshen Eps Machine has built a reputation for providing cutting-edge technology and reliable solutions for EPS manufacturers around the world.

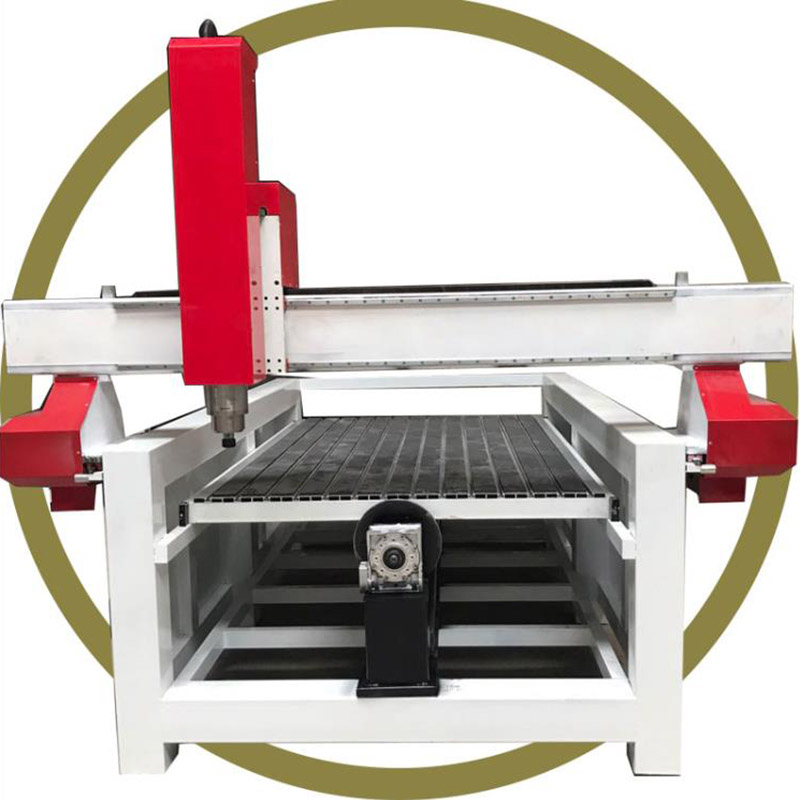

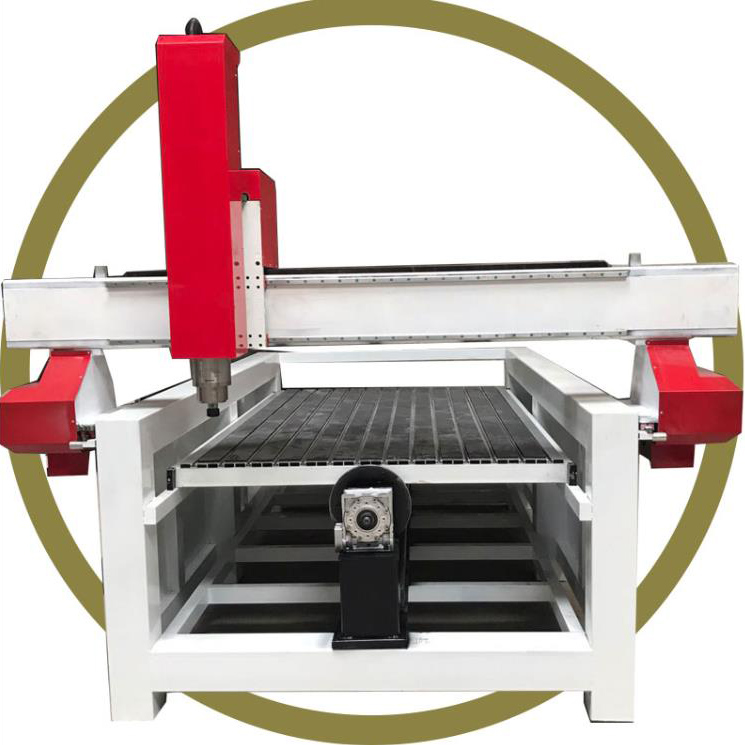

At the heart of our offerings are our EPS CNC Cutting Machines, engineered to perfection to meet diverse client needs. Our DSQ2000B-DSQ6000B Block Cutting Machine series is designed to deliver precision and efficiency, catering to various production scales with unparalleled consistency. Alongside, our DSQ2000C-6000C Block Cutting Machine series offers advanced features tailored for intricate and demanding cutting requirements, ensuring optimal performance and productivity.

Dongshen Eps Machine prides itself on its robust technical team that not only supports the design and implementation of new EPS factories but also enhances existing facilities by optimizing energy consumption and boosting production capacity. We provide comprehensive turn-key EPS projects, inclusive of custom-built EPS machines and moulds, ensuring our solutions are perfectly aligned with our client's unique specifications.

Our commitment to quality extends beyond manufacturing; we also supply vital EPS raw material production equipment, further cementing our role as a trusted partner in the EPS manufacturing ecosystem. At Dongshen Eps Machine, excellence and reliability are not just promises but a tradition.

At the heart of our offerings are our EPS CNC Cutting Machines, engineered to perfection to meet diverse client needs. Our DSQ2000B-DSQ6000B Block Cutting Machine series is designed to deliver precision and efficiency, catering to various production scales with unparalleled consistency. Alongside, our DSQ2000C-6000C Block Cutting Machine series offers advanced features tailored for intricate and demanding cutting requirements, ensuring optimal performance and productivity.

Dongshen Eps Machine prides itself on its robust technical team that not only supports the design and implementation of new EPS factories but also enhances existing facilities by optimizing energy consumption and boosting production capacity. We provide comprehensive turn-key EPS projects, inclusive of custom-built EPS machines and moulds, ensuring our solutions are perfectly aligned with our client's unique specifications.

Our commitment to quality extends beyond manufacturing; we also supply vital EPS raw material production equipment, further cementing our role as a trusted partner in the EPS manufacturing ecosystem. At Dongshen Eps Machine, excellence and reliability are not just promises but a tradition.

EPS CUTTING MACHINE

-

Fully automatic cutting line for expanded polystyrene(eps)

-

EPS CNC Router

-

EPS foam carving machine

-

Automatic EPS block cutting line

-

Continuous EPS block cutting line

-

EPS cutting line with automatic wire setting

-

EPS foam carving machine

-

EPS CNC Router

-

EPS CNC Router

-

DSQ2000B-DSQ6000B Block Cutting Machine

-

DSQ2000C-6000C Block Cutting Machine

-

EPS CNC Cutting Machine

EPS CUTTING MACHINE FAQ

What is EPS cut?▾

● Understanding EPS Cut

Expanded Polystyrene (EPS) is a versatile and widely used material in various industries, known for its lightweight and insulating properties. An EPS cut refers to the process of shaping and resizing EPS blocks into specific forms and dimensions to meet diverse application requirements. This intricate procedure is crucial in creating products ranging from packaging materials to architectural elements.

○ The Significance of EPS Cutting

EPS cutting is an essential process that enables manufacturers to maximize the utility of EPS by tailoring it to precise specifications. The importance of accurate cutting cannot be overstated, as it ensures that the final product maintains its structural integrity and functional efficiency. Properly executed EPS cuts lead to minimized material wastage, cost savings, and enhanced performance in the product's end use.

○ Techniques and Methods

There are several techniques employed in the EPS cutting process, each selected based on the desired outcome and the complexity of the shapes required. Some of the common methods include hot wire cutting, CNC cutting, and die-cutting.

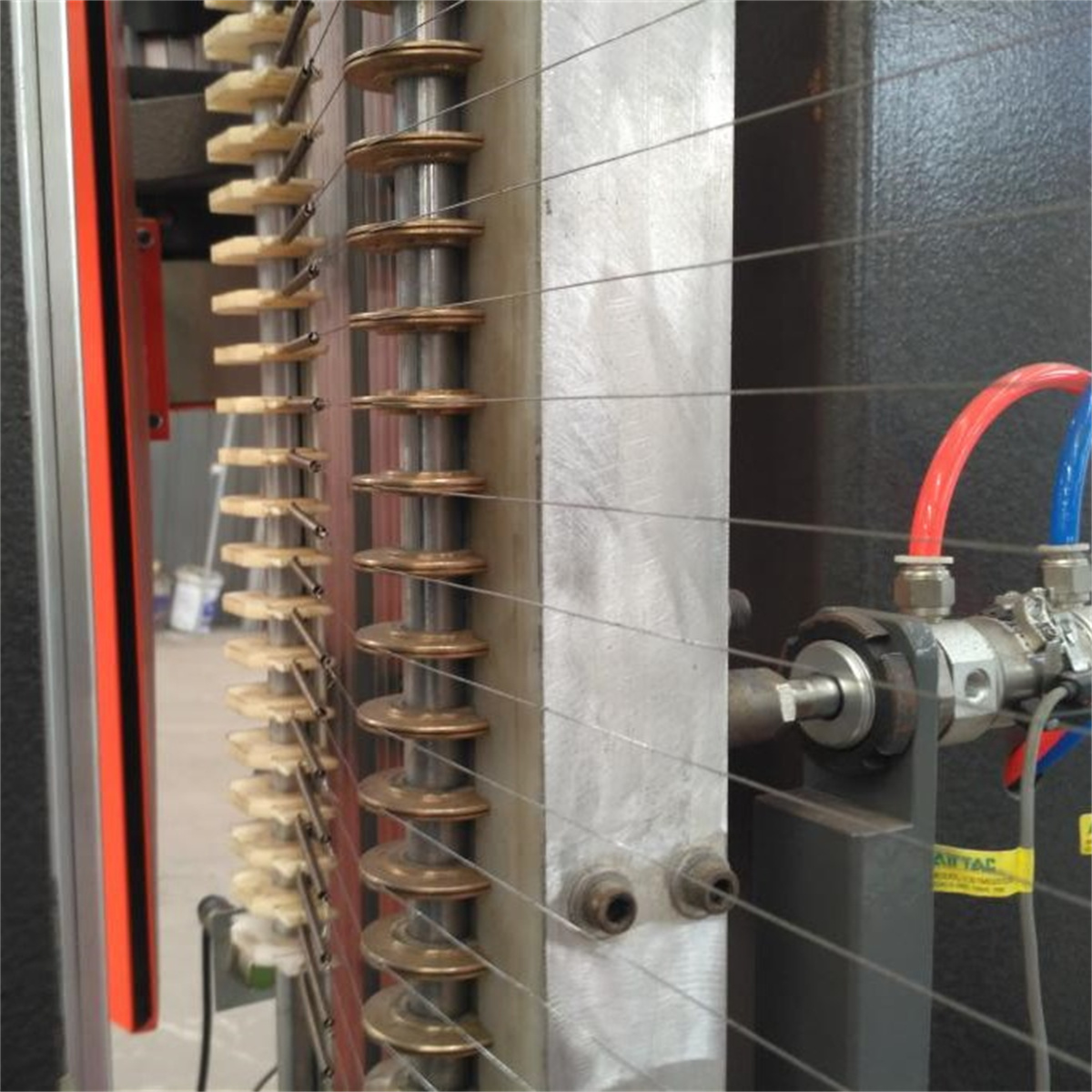

1. Hot Wire Cutting: This technique uses a heated wire to melt through the EPS, allowing for smooth and precise cuts. It is highly effective for creating intricate shapes and complex designs. The consistency and accuracy of the cuts make hot wire cutting a preferred choice for industries where detail and precision are paramount.

2. CNC Cutting: Computer Numerical Control (CNC) cutting employs computer-driven machinery to execute precise cuts based on digital designs. This method is particularly advantageous for mass production as it ensures uniformity and high accuracy across all pieces. CNC cutting is ideal for large-scale projects requiring consistent and repeatable results.

3. Die-Cutting: This process involves using a die to stamp out shapes from EPS sheets. It is efficient for producing simple, repetitive shapes and is widely used in the packaging industry. Die-cutting is both time-efficient and cost-effective, making it suitable for high-volume production runs.

○ Advantages of Using an EPS Cutting Machine Manufacturer

Investing in high-quality EPS cutting machines from reputable manufacturers can significantly enhance the efficiency and quality of the cutting process. These machines are engineered to deliver precision, speed, and reliability, ensuring that each cut meets the specific requirements of the project. Working with an experienced EPS cutting machine manufacturer offers several benefits:

- Expertise and Innovation: Leading manufacturers bring a wealth of expertise and the latest technological advancements to the table. Their commitment to innovation ensures that the machines are equipped with cutting-edge features that enhance performance and user experience.

- Customization: Reputable manufacturers understand that different industries have unique needs. They offer customized solutions that cater to specific project requirements, ensuring optimal results. This level of customization means businesses can achieve more with their EPS cutting processes, from intricate architectural designs to robust packaging solutions.

- Support and Maintenance: Established manufacturers provide comprehensive support and maintenance services, ensuring that the machines operate at peak efficiency. Regular maintenance and timely repairs help in extending the lifespan of the equipment, thereby maximizing the return on investment.

○ Conclusion

Incorporating advanced EPS cutting techniques is pivotal for industries relying on the versatility and adaptability of EPS material. By leveraging the expertise and technological prowess of a trusted EPS cutting machine manufacturer, businesses can achieve superior accuracy, efficiency, and productivity in their operations. The process of EPS cutting is more than just shaping a material; it is about transforming potential into performance, ensuring that the final product meets the highest standards of quality and functionality. By focusing on precision and leveraging modern technology, manufacturers can unlock the full potential of EPS, making it an invaluable asset across various applications.

How do you cut EPS blocks?▾

Cutting expanded polystyrene (EPS) blocks is a process that demands precision and the right techniques to avoid compromising the integrity of the material. Whether you're a professional in the construction industry or a DIY enthusiast, understanding the nuances of cutting EPS can save time, effort, and materials. This guide delves into various methods and tools used for cutting EPS blocks efficiently.

Mechanical cutting involves using handheld or power tools. These methods are often employed for their accessibility and ease of use.

Using a hand saw is one of the simplest and most common ways to cut EPS blocks. Opt for a fine-toothed saw to make smoother cuts and reduce material wastage. Start by marking the desired cut line on the EPS block. Hold the block firmly to prevent it from moving, then saw along the marked line using steady, even strokes. This method is most suitable for small projects or when precision is not the top priority.

A jigsaw offers more versatility compared to a hand saw, especially for intricate cuts or curved shapes. Equip your jigsaw with a fine blade specifically designed for cutting foam materials. Similar to using a hand saw, mark the cut line and secure the EPS block. Guide the jigsaw along the line, applying consistent pressure. The jigsaw's rapid motion will help you achieve clean, precise cuts quickly.

Thermal cutting methods involve using heat to cut through the EPS blocks. These techniques are highly effective in reducing material crumbling and ensuring smooth edges.

A hot wire cutter is a specialized tool that uses a heated wire to slice through EPS blocks. The heat melts the foam, resulting in clean and precise cuts with minimal debris. To use this method, set up the hot wire cutter according to the manufacturer's instructions. Position the EPS block on the cutter and guide it along your desired cut line. The hot wire will effortlessly glide through the material, making it an ideal choice for detailed and large-scale projects.

For high-precision and large-scale cutting requirements, an EPS CNC cutting machine is the epitome of efficiency and accuracy. This computer-controlled machine uses a combination of mechanical and thermal cutting techniques to produce intricate shapes and designs. The EPS CNC cutting machine is programmed via specialized software that allows for detailed customization. When the EPS block is fed into the machine, the programmed instructions guide the cutting process, ensuring impeccable accuracy and uniformity. This method is highly recommended for industrial applications and projects requiring consistent quality.

Accurate cuts are crucial to avoid unwanted gaps or overlaps, which can affect the thermal performance of the EPS blocks. Always measure and mark your cut lines carefully before starting the cutting process. Use a straightedge or a template to guide your cuts for better precision.

Avoiding material waste is not only cost-effective but also environmentally responsible. When planning your cuts, aim to maximize the use of each EPS block by strategically placing your cut lines. This ensures that even the offcuts can be utilized for smaller sections or additional projects.

After cutting, the edges of the EPS blocks may need to be finished to ensure a smooth and professional look. Sandpaper can be used to gently smooth out any rough edges. For a more polished finish, consider using a specialized edge-finishing tool designed for foam materials.

In conclusion, cutting EPS blocks effectively requires the right tools and techniques. Whether you opt for mechanical or thermal methods, understanding their applications and limitations will help you achieve the desired results. For large-scale and precision-demanding projects, an EPS CNC cutting machine stands out as the best option, ensuring efficient and accurate cuts every time. By following these guidelines, you can work with EPS blocks like a true professional.

Methods of Cutting EPS Blocks

● Mechanical Cutting

Mechanical cutting involves using handheld or power tools. These methods are often employed for their accessibility and ease of use.

○ Hand Saw

Using a hand saw is one of the simplest and most common ways to cut EPS blocks. Opt for a fine-toothed saw to make smoother cuts and reduce material wastage. Start by marking the desired cut line on the EPS block. Hold the block firmly to prevent it from moving, then saw along the marked line using steady, even strokes. This method is most suitable for small projects or when precision is not the top priority.

○ Jigsaw

A jigsaw offers more versatility compared to a hand saw, especially for intricate cuts or curved shapes. Equip your jigsaw with a fine blade specifically designed for cutting foam materials. Similar to using a hand saw, mark the cut line and secure the EPS block. Guide the jigsaw along the line, applying consistent pressure. The jigsaw's rapid motion will help you achieve clean, precise cuts quickly.

● Thermal Cutting

Thermal cutting methods involve using heat to cut through the EPS blocks. These techniques are highly effective in reducing material crumbling and ensuring smooth edges.

○ Hot Wire Cutter

A hot wire cutter is a specialized tool that uses a heated wire to slice through EPS blocks. The heat melts the foam, resulting in clean and precise cuts with minimal debris. To use this method, set up the hot wire cutter according to the manufacturer's instructions. Position the EPS block on the cutter and guide it along your desired cut line. The hot wire will effortlessly glide through the material, making it an ideal choice for detailed and large-scale projects.

Advanced Cutting Techniques

● EPS CNC Cutting Machine

For high-precision and large-scale cutting requirements, an EPS CNC cutting machine is the epitome of efficiency and accuracy. This computer-controlled machine uses a combination of mechanical and thermal cutting techniques to produce intricate shapes and designs. The EPS CNC cutting machine is programmed via specialized software that allows for detailed customization. When the EPS block is fed into the machine, the programmed instructions guide the cutting process, ensuring impeccable accuracy and uniformity. This method is highly recommended for industrial applications and projects requiring consistent quality.

Practical Tips

● Ensuring Accurate Cuts

Accurate cuts are crucial to avoid unwanted gaps or overlaps, which can affect the thermal performance of the EPS blocks. Always measure and mark your cut lines carefully before starting the cutting process. Use a straightedge or a template to guide your cuts for better precision.

● Minimizing Material Waste

Avoiding material waste is not only cost-effective but also environmentally responsible. When planning your cuts, aim to maximize the use of each EPS block by strategically placing your cut lines. This ensures that even the offcuts can be utilized for smaller sections or additional projects.

● Finishing the Edges

After cutting, the edges of the EPS blocks may need to be finished to ensure a smooth and professional look. Sandpaper can be used to gently smooth out any rough edges. For a more polished finish, consider using a specialized edge-finishing tool designed for foam materials.

In conclusion, cutting EPS blocks effectively requires the right tools and techniques. Whether you opt for mechanical or thermal methods, understanding their applications and limitations will help you achieve the desired results. For large-scale and precision-demanding projects, an EPS CNC cutting machine stands out as the best option, ensuring efficient and accurate cuts every time. By following these guidelines, you can work with EPS blocks like a true professional.

What cutting machine is best for EPP?▾

When selecting the ideal cutting machine for Expanded Polypropylene (EPP), it's crucial to consider several factors that ensure efficiency, precision, and quality. EPP, due to its flexible yet durable nature, is widely utilized in various industries including automotive, packaging, and construction. The right cutting machine can enhance productivity and product quality, making it essential to choose wisely. Among the options available, the EPS Foam Cutting Machine stands out as a premier choice for EPP applications.

EPP requires exact cuts to maintain the integrity of the material. The EPS Foam Cutting Machine excels in delivering precise cuts, crucial for applications such as automotive components or protective packaging where accuracy is paramount. This machine utilizes advanced technology that minimizes material waste and ensures that each cut is clean and accurate. The precision of the EPS Foam Cutting Machine not only meets but exceeds industry standards, ensuring that your EPP products are of the highest quality.

One of the key features of the EPS Foam Cutting Machine is its versatility. It is designed to handle various densities and thicknesses of EPP, making it suitable for a wide range of applications. Whether you're dealing with lightweight packaging materials or denser automotive components, this machine can adapt to your needs. The ability to customize settings for different types of EPP enhances its utility, making it a versatile tool for any manufacturing process.

Operational efficiency is a critical factor in any manufacturing environment. The EPS Foam Cutting Machine is engineered for high-speed operation without compromising on accuracy or safety. Its advanced control systems allow for smooth and continuous cuts, reducing downtime and increasing throughput. This efficiency translates to a higher volume of production, enabling businesses to meet their demands effectively.

Safety is paramount when dealing with cutting machines. The EPS Foam Cutting Machine is designed with safety features that protect operators from potential hazards. Its user-friendly interface ensures that operators can easily adjust settings and monitor the cutting process without extensive training. This combination of safety and ease of use makes it an ideal choice for businesses looking to integrate a cutting machine into their workflow without significant training or safety risks.

Investing in a cutting machine is a significant decision for any business. The EPS Foam Cutting Machine offers excellent value for money with its durability, low maintenance requirements, and operational efficiency. By minimizing waste and maximizing productivity, it ensures a rapid return on investment. Its robust construction means it can withstand the rigors of daily use, providing long-term reliability and consistent performance.

Sustainability is becoming increasingly important in manufacturing. The EPS Foam Cutting Machine is designed to be environmentally friendly, with features that reduce energy consumption and material waste. Its precision cutting capabilities mean fewer off-cuts and scraps, contributing to a more sustainable manufacturing process. This environmental consideration makes it an attractive option for businesses committed to reducing their carbon footprint.

In conclusion, the EPS Foam Cutting Machine is the best choice for cutting EPP due to its precision, versatility, efficiency, safety, cost-effectiveness, and environmental friendliness. Its advanced technology and user-friendly design make it a valuable asset for any industry that utilizes EPP. By choosing this machine, businesses can enhance their production processes, ensuring high-quality outcomes and operational efficiency.

● Precision and Efficiency

EPP requires exact cuts to maintain the integrity of the material. The EPS Foam Cutting Machine excels in delivering precise cuts, crucial for applications such as automotive components or protective packaging where accuracy is paramount. This machine utilizes advanced technology that minimizes material waste and ensures that each cut is clean and accurate. The precision of the EPS Foam Cutting Machine not only meets but exceeds industry standards, ensuring that your EPP products are of the highest quality.

● Versatility and Adaptability

One of the key features of the EPS Foam Cutting Machine is its versatility. It is designed to handle various densities and thicknesses of EPP, making it suitable for a wide range of applications. Whether you're dealing with lightweight packaging materials or denser automotive components, this machine can adapt to your needs. The ability to customize settings for different types of EPP enhances its utility, making it a versatile tool for any manufacturing process.

● Efficiency in Operation

Operational efficiency is a critical factor in any manufacturing environment. The EPS Foam Cutting Machine is engineered for high-speed operation without compromising on accuracy or safety. Its advanced control systems allow for smooth and continuous cuts, reducing downtime and increasing throughput. This efficiency translates to a higher volume of production, enabling businesses to meet their demands effectively.

● Safety and User-Friendliness

Safety is paramount when dealing with cutting machines. The EPS Foam Cutting Machine is designed with safety features that protect operators from potential hazards. Its user-friendly interface ensures that operators can easily adjust settings and monitor the cutting process without extensive training. This combination of safety and ease of use makes it an ideal choice for businesses looking to integrate a cutting machine into their workflow without significant training or safety risks.

● Cost-Effectiveness

Investing in a cutting machine is a significant decision for any business. The EPS Foam Cutting Machine offers excellent value for money with its durability, low maintenance requirements, and operational efficiency. By minimizing waste and maximizing productivity, it ensures a rapid return on investment. Its robust construction means it can withstand the rigors of daily use, providing long-term reliability and consistent performance.

● Environmental Considerations

Sustainability is becoming increasingly important in manufacturing. The EPS Foam Cutting Machine is designed to be environmentally friendly, with features that reduce energy consumption and material waste. Its precision cutting capabilities mean fewer off-cuts and scraps, contributing to a more sustainable manufacturing process. This environmental consideration makes it an attractive option for businesses committed to reducing their carbon footprint.

In conclusion, the EPS Foam Cutting Machine is the best choice for cutting EPP due to its precision, versatility, efficiency, safety, cost-effectiveness, and environmental friendliness. Its advanced technology and user-friendly design make it a valuable asset for any industry that utilizes EPP. By choosing this machine, businesses can enhance their production processes, ensuring high-quality outcomes and operational efficiency.

How do you cut polystyrene molding?▾

Polystyrene molding offers considerable benefits over traditional wood molding, including being lightweight, cost-effective, and easy to handle. However, achieving precise cuts in polystyrene molding requires understanding the right techniques and tools. This guide will walk you through the best practices for cutting polystyrene molding effectively and efficiently.

To cut polystyrene molding, you don't need specialized equipment; a regular wood saw will suffice. However, the choice of the blade is critical. Opt for a saw blade with fewer than 120 teeth. A 36-tooth blade is ideal as it allows you to cut through the polystyrene quickly and cleanly, minimizing any risk of melting the plastic. The key here is the speed of cutting; moving the saw briskly through the material reduces heat buildup and avoids melting.

Ensuring that your saw operates at the correct RPM (revolutions per minute) is crucial for a clean cut. The ideal range for cutting polystyrene is between 2,400 and 3,000 RPM. If the RPM is too low, the saw can generate excessive heat, causing the polystyrene to melt. Conversely, too high an RPM can make the saw vibrate excessively, leading to uneven cuts. Keeping the saw in this optimal range ensures a smooth and efficient operation.

When cutting polystyrene molding, it's essential to maintain a steady hand and ensure smooth, continuous movements. Start the saw and let it reach the desired RPM before making contact with the polystyrene. Gently guide the saw through the material, applying consistent pressure. Avoid stopping mid-cut as this can create uneven edges and increase the risk of melting.

If a saw is not available, a chopper can also be used to cut polystyrene molding. The chopper should have a sharp blade and be capable of making clean, straight cuts. Position the molding securely in the chopper, align the blade with the desired cutting line, and bring the blade down swiftly to ensure a neat cut.

Joining polystyrene molding pieces requires the right type of glue. Plastic glue is recommended for its quick drying time and strong bonding properties. For an easily accessible alternative, PVC glue from any hardware store will work; however, it takes approximately an hour to dry. Applying the adhesive evenly and ensuring the surfaces are clean before joining will result in a secure bond.

Polystyrene frames can be joined using an underpinner, similar to wood molding. One important consideration is to avoid placing pins too close to the edge of the frame corners, as this can cause splitting. Ensure that the underpinner is set to the correct pressure to avoid damaging the polystyrene while securely joining the pieces.

For those looking for more efficient and professional-grade cutting of polystyrene molding, investing in machines from Eps Cutting Machine manufacturer can be advantageous. These machines are designed to handle polystyrene with precision, ensuring clean cuts at optimal speeds. The specialized equipment from Eps Cutting Machine manufacturer offers tailored solutions that cater specifically to the properties of polystyrene, delivering consistently excellent results with minimal effort.

By adhering to these guidelines and considering the use of specialized cutting machines, you can achieve precise, clean cuts in your polystyrene molding projects, enhancing both the aesthetic and functional quality of your work.

Selecting the Right Saw and Blade

To cut polystyrene molding, you don't need specialized equipment; a regular wood saw will suffice. However, the choice of the blade is critical. Opt for a saw blade with fewer than 120 teeth. A 36-tooth blade is ideal as it allows you to cut through the polystyrene quickly and cleanly, minimizing any risk of melting the plastic. The key here is the speed of cutting; moving the saw briskly through the material reduces heat buildup and avoids melting.

● Optimal Saw RPM

Ensuring that your saw operates at the correct RPM (revolutions per minute) is crucial for a clean cut. The ideal range for cutting polystyrene is between 2,400 and 3,000 RPM. If the RPM is too low, the saw can generate excessive heat, causing the polystyrene to melt. Conversely, too high an RPM can make the saw vibrate excessively, leading to uneven cuts. Keeping the saw in this optimal range ensures a smooth and efficient operation.

Techniques for Cutting

When cutting polystyrene molding, it's essential to maintain a steady hand and ensure smooth, continuous movements. Start the saw and let it reach the desired RPM before making contact with the polystyrene. Gently guide the saw through the material, applying consistent pressure. Avoid stopping mid-cut as this can create uneven edges and increase the risk of melting.

● Using a Chopper

If a saw is not available, a chopper can also be used to cut polystyrene molding. The chopper should have a sharp blade and be capable of making clean, straight cuts. Position the molding securely in the chopper, align the blade with the desired cutting line, and bring the blade down swiftly to ensure a neat cut.

Adhesives for Joining

Joining polystyrene molding pieces requires the right type of glue. Plastic glue is recommended for its quick drying time and strong bonding properties. For an easily accessible alternative, PVC glue from any hardware store will work; however, it takes approximately an hour to dry. Applying the adhesive evenly and ensuring the surfaces are clean before joining will result in a secure bond.

● Using an Underpinner

Polystyrene frames can be joined using an underpinner, similar to wood molding. One important consideration is to avoid placing pins too close to the edge of the frame corners, as this can cause splitting. Ensure that the underpinner is set to the correct pressure to avoid damaging the polystyrene while securely joining the pieces.

Efficient Cutting with Eps Cutting Machine Manufacturer

For those looking for more efficient and professional-grade cutting of polystyrene molding, investing in machines from Eps Cutting Machine manufacturer can be advantageous. These machines are designed to handle polystyrene with precision, ensuring clean cuts at optimal speeds. The specialized equipment from Eps Cutting Machine manufacturer offers tailored solutions that cater specifically to the properties of polystyrene, delivering consistently excellent results with minimal effort.

By adhering to these guidelines and considering the use of specialized cutting machines, you can achieve precise, clean cuts in your polystyrene molding projects, enhancing both the aesthetic and functional quality of your work.