Vula indlela yokubumba yomjovo ye-dongshen ye-dongshen

Isifinyezo se-EPS(I-PolySTrere enwebekayo) Ukukhiqizwa okubonakalayo okuluhlaza

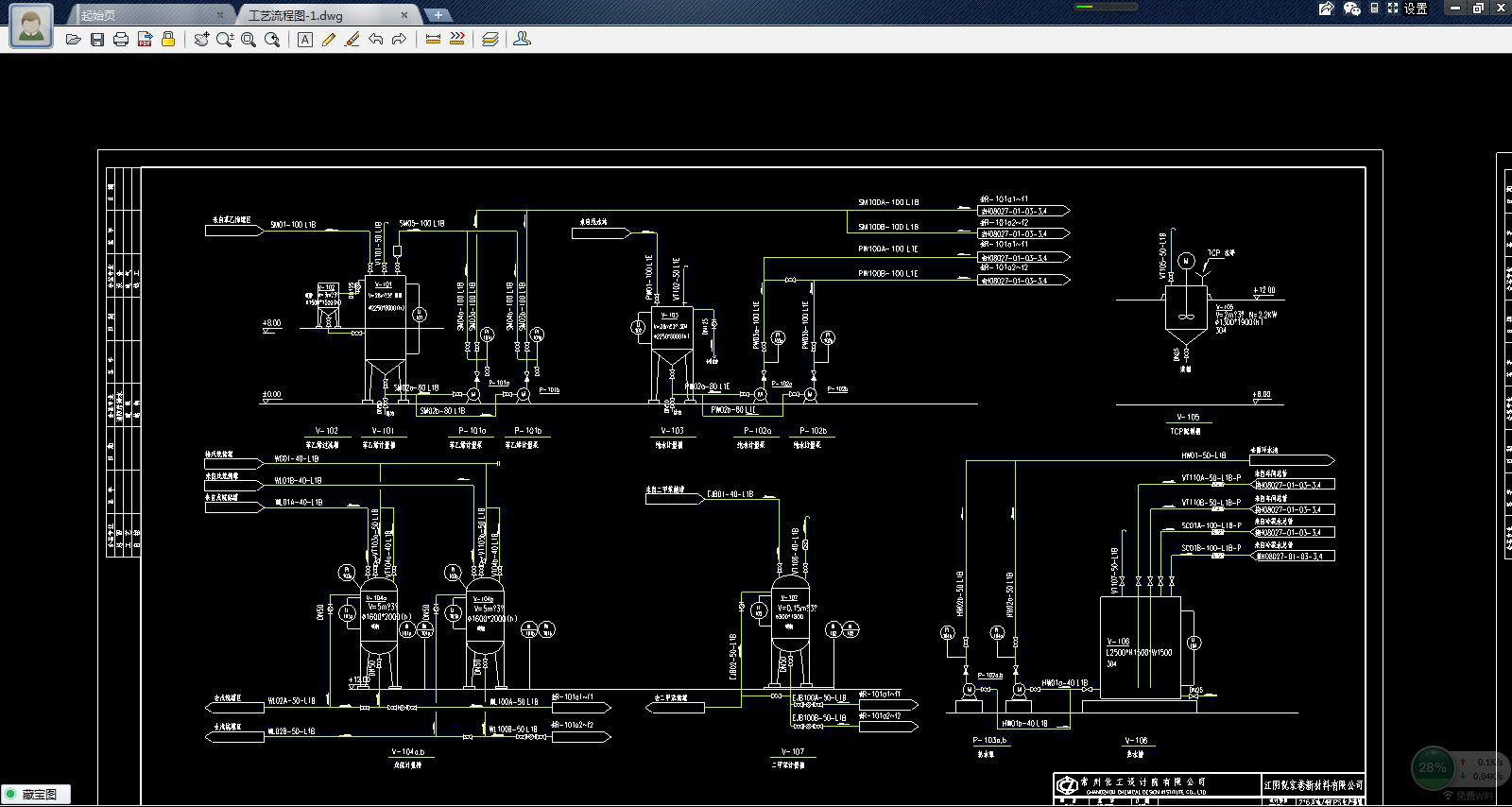

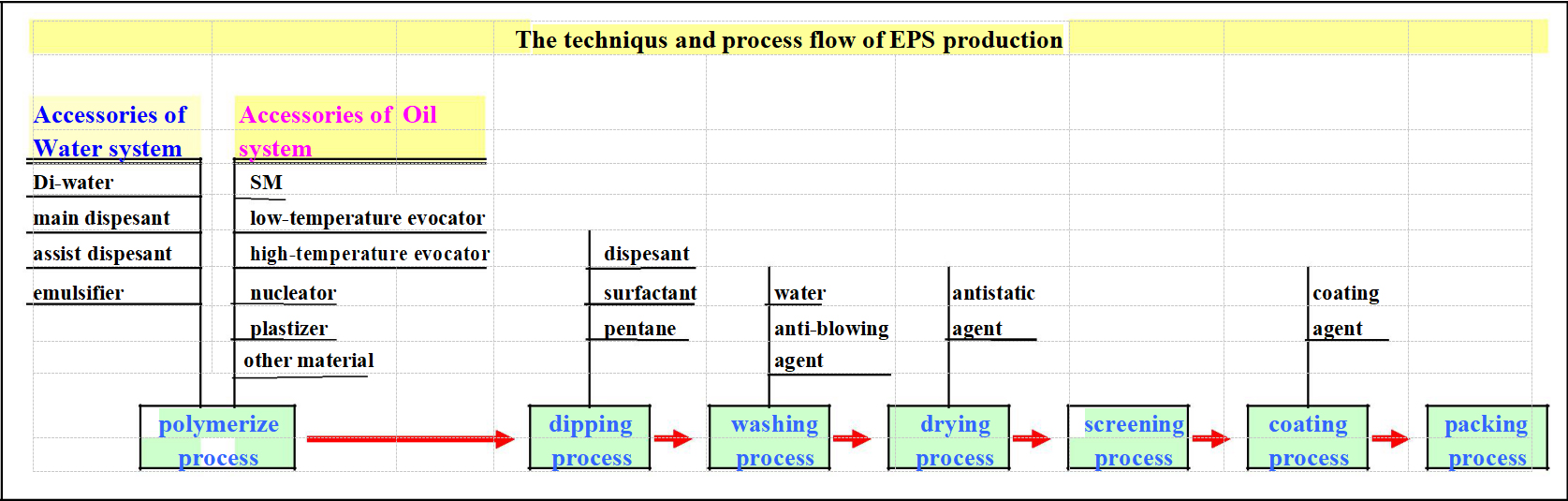

Inqubo yokugeleza Isingeniso

Inqubo yayo eyodwa - Indlela Yezinyathelo kufaka phakathi i-polymerization, ukungahambi kahle, ukupholisa, ukugeza, ukugeza, ukumiswa, ukufihla, ukuhlanganisa, ukuhambisa. Isikhathi sokukhiqiza somjikelezo wokukhiqiza sokukhiqizwa kwe-EPS singamahora ayi-16 ~ 17.

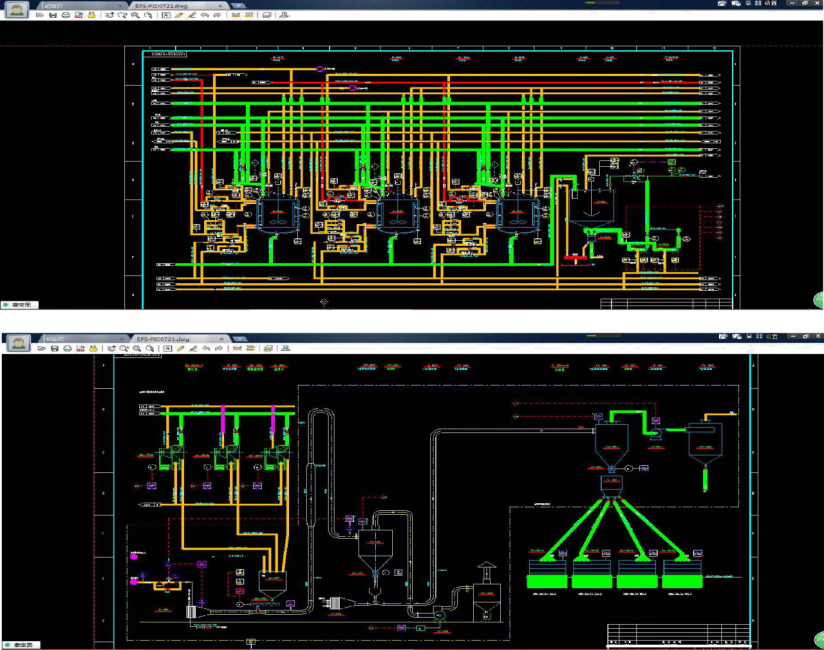

(1) I-polymerization kanye nokuthunyelwa

I-Polymerization kanye nokufakwa umnyuziki kufakwa kwi-Reactor. Ngaphansi kokulimala okuthile, i-SM izokopela. Ngokuvuselelwa okuyisikhumbuzo, i-SM izonwetshwa futhi inqunywe ibe yimichilo, bese ikhomba amaconsi e-SM Amafutha okumisa emanzini ngenxa yengcindezi engaphezulu. Kukhona ama-dispersants asomisa emanzini ukugwema izinhlayiya ze-SM futhi zixhumane ndawonye. Kule nqubo amandla ahlukile kufanele abe makhulu kunamandla okuxhuma ukuze uqinisekise okuphansi - ama-polyerization wokushisa.

I-Low - Ukuvuselelwa kwe-polymerization ukusabela kusebenza ekwehleni kukawoyela we-SM, ukushisa okukhishwe ekusabelaneni kuzosuswa ngamanzi apholile ku-Clip Set. Ukususa ukushisa ngesikhathi, kufanele siqinisekise umsebenzi ojwayelekile wokuphinda usebenzise kabusha uhlelo lwamanzi ngesikhathi sokuphendula. Ngaphandle kwalokho, izinga lokushisa elikuphendukayo lizoba liphezulu kakhulu, okuholela ekuphenduleni okusheshayo nokuvunywa okuphezulu.

Inqubo yokukhiqiza ubuhlalu ilawulwa ngesandla, ngesikhathi senqubo, izinga lokushisa kufanele lilawulwe kahle ukugwema ukuguquguquka okukhulu, ngenye indlela, ububanzi obuhlalu buzobhujiswa. Ngaleso sikhathi, ukubonwa kaningi kwamasampula kubalulekile ukulawula usayizi wobuhlalu.

Ngokulungiswa kwe-Light Weight Caco3 ne-TCP, usayizi wobuhlalu ungalawulwa.

Uhlelo lwe-DCS lusetshenziselwa ukulawulwa kokushisa kuyo yonke inqubo yokushisa, i-polymerization, ukuwohloka, ukuphakama - ukuphendula okushisa, nokupholisa. Ukuqinisekisa ukukhiqizwa kokuphepha, uhlelo lwe-DCS luzolawula isimo se-templet kanye nesikhathi, kanye ne-alamu ngaphezulu - izinga lokushisa noma icala lokucindezela.

Lapho isilinganiso sokuguqulwa se-SM sifinyelela cishe ama-75% (cishe amahora ama-4 kuye kwangama-5 ngaphansi kokushisa okungapheli), inani elithile le-ejenti elishayelwe kufanele lingezwe. Ngemuva kokufakwa kokuthunyelwa kanye ne-polymerization ngaphansi kwesikhathi esithile nengcindezi, singathola ubuhlalu be-eps.

I-ejenti evuthayo yokufakwa kokufakwayo ifakwe ku-kettle ngokulinganisa ipompo, futhi inesisindo ngokunembile ngesisindo sedivayisi. Ngemuva kwenqubo ephakeme - Inqubo ye-temptere, lapho kuphola kumazinga okushisa acacisiwe, okuqukethwe kungakhishwa ethangini lokuwasha.

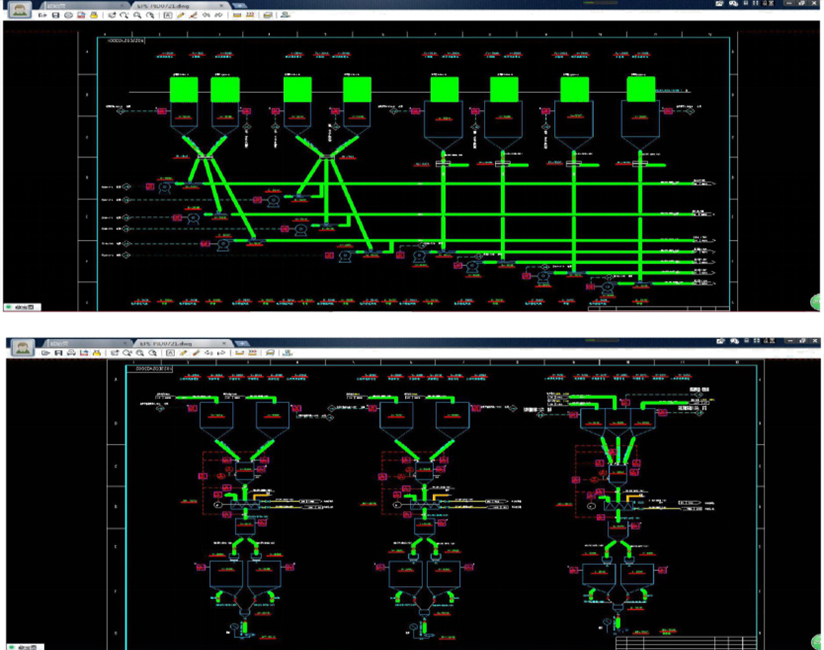

(2) ukugeza

Ukungcola okufana nokuhlakazeka futhi ama-defloculates kumele asuswe ngokugeza. Ngemuva kokuhlanza, ubuhlalu be-EPS buzomiswa ngama-dehydration centrifugal ukususa iningi lamanzi, futhi ulungele ukoma okuqhubekayo.

Singasebenzisa futhi i-de - i-ejenti ye-Foaming ukususa ukungcola.

(3) ukomisa

Ngemuva kwe-centrifugal dehydration, kuzoba khona okusele kwamanzi okungu-3% ngaphezulu kobuhlalu be-EPS (okuqukethwe kwamanzi kakhulu kuzothonya ikhwalithi yemikhiqizo ye-EPS), ngakho-ke inqubo eyengeziwe yomiswa iyadingeka, phakathi nale nqubo, imihla ebuhlanya ye-EPS yomiswa ngomoya oshisayo. Ukushaywa ngumoya oshisayo, amanzi ahlala kuwo abe umusi, khona-ke lolu hlobo lwegesi - Ingxube eqinile ingena ekuhlungeni kwesikebhe, kanti ubuhlalu buzokhipha indawo yokuhlunga eliphansi enkabeni yohlukanisi, bese ucindezela umoya onomswakama oshisayo ugeleza ngokusebenzisa ipayipi lesikhungo. Ngale ndlela ubuhlalu buzomiswa.

Ngemuva kokomiswa komoya okushisayo, ubuhlalu budinga ukusehliswa ngumoya obandayo ukuze uphinde unciphise okuqukethwe kwamanzi, bese ulungela ukuhlolwa. Ukuvimbela ukunqwabelana kukagesi, umenzeli we-antistatic kufanele wengezwe ngesikhathi sokomiswa.

Izinga lokushisa lokumisa lilawulwa uhlelo lwe-DCS.

(4) ukuhlolwa

Usayizi we-EPS ubuhlalu obomile akalingani, ulwazi lokuhlola luyadingeka ukuhlukanisa ubuhlalu ngokucaciswa nokudlulisela kuma-silos ahlukene.

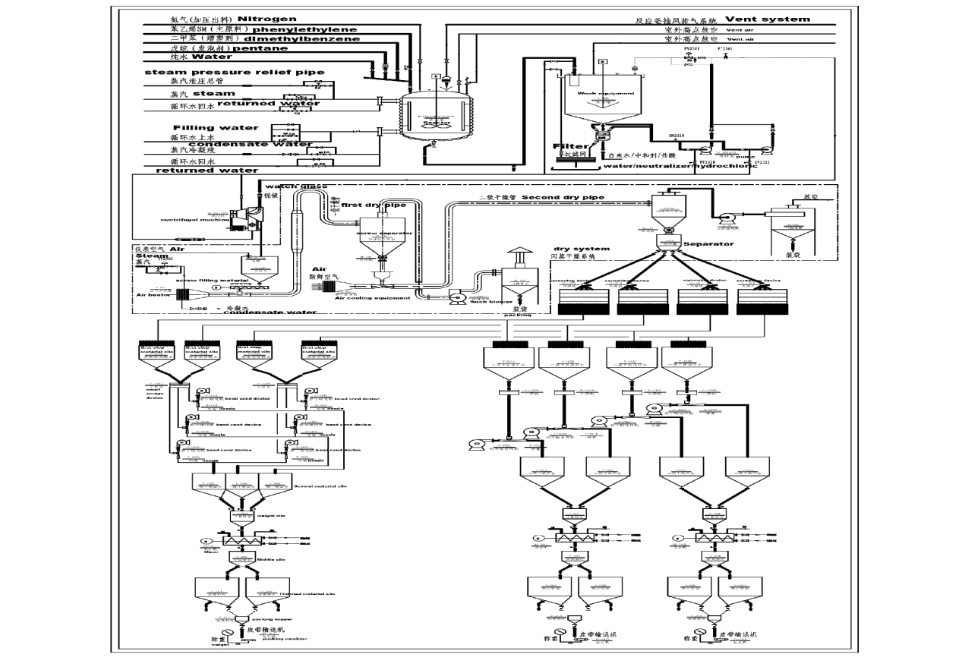

(5) coating

Ngesikhathi sokukhiqiza i-EPS, ukugcinwa, izinto zokuhamba kanye nenqubo, ukuphunyula kwe-ejenti yokuqhuma akunakugwenywa. Uma u-Agent Okakhulu kakhulu elahlekile, kuzokwenzeka izinkinga eziningi, njengokuncipha kwezinga elikhulayo, ukwanda kobunzima, ubunzima bokwakha, njll. Ukwelula ukulahleka kwe-ejenti evumayo, ukusetshenziswa kwe-ejenti ye-EPS ebusweni.

Icala

NgeDongshen ehola indlela, ikusasa lokubumba okungokomfanekiso okuthi styrofoam libonisa amandla angabi nalo, lifaka umbono othembisayo embonini. Sijoyine njengoba siqhubeka nokusungula futhi siguqule inqubo yokukhiqiza ebonakalayo ye-EPS eluhlaza. Ekuphetheni, ukuhlanganiswa komjovo we-styrofoam eDongshen's Eps Raw ebonakalayo kusebenza njengophawu lwemboni. Sivivinya izilawuli zekhwalithi eziqinile, ukuhlanganisa ubuchwepheshe obuthuthukile ukuletha izinto eziphakeme ze-EPS ezingavuthiwe kubalingani bethu namakhasimende. Hlola izimangaliso ze-Styrofoam umjovo ukubumba nge-dongshen namuhla.