Wholesale Polystyrene Tool: EPS Fish Box Mould

Product Main Parameters

| Parameter | Details |

|---|---|

| Steam Chamber | 1200*1000mm, 1400*1200mm, 1600*1350mm, 1750*1450mm |

| Mould Size | 1120*920mm, 1320*1120mm, 1520*1270mm, 1670*1370mm |

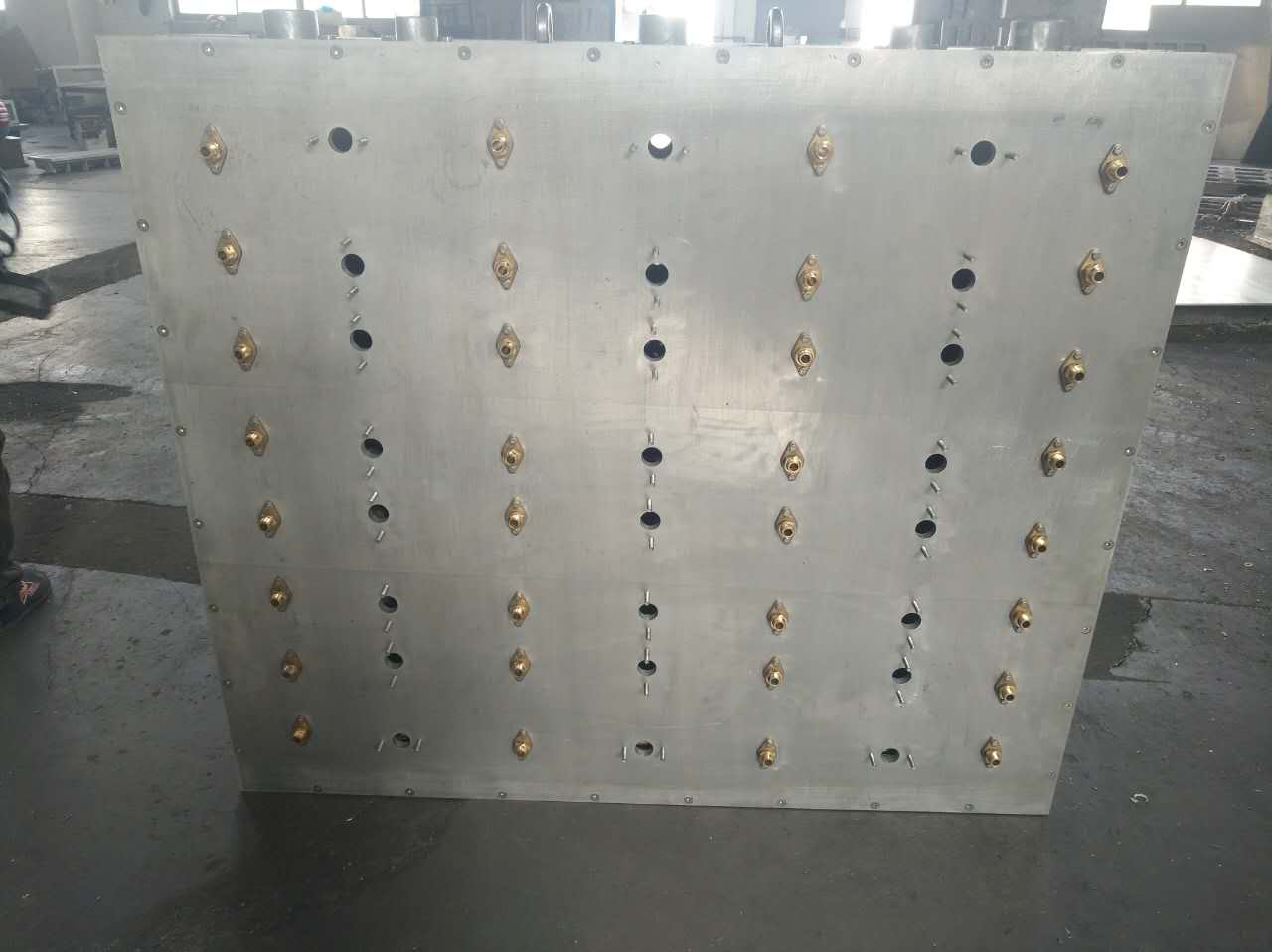

| Patterning | Wood or PU by CNC |

| Machining | Fully CNC |

| Alu Alloy Plate Thickness | 15mm |

| Packing | Plywood Box |

| Delivery | 25~40 days |

Common Product Specifications

| Specification | Details |

|---|---|

| Material | High-quality Aluminum Alloy with Teflon Coating |

| Tolerance | Within 1mm |

| Design Capability | Custom designs available based on client requirements |

Product Manufacturing Process

The manufacturing process of our EPS Fish Box Moulds involves the careful selection of high-grade aluminum alloy, ensuring robustness and longevity. Initially, raw aluminum ingots are melted and cast into preliminary mould shapes. Using state-of-the-art CNC machining technology, these casts are then precisely cut and formed to achieve exact dimensions with a tolerance of within 1mm. The mould cavities and cores are subsequently coated with Teflon to ensure easy demoulding and durability. Our engineering team, with extensive experience, meticulously oversees every step, from patterning to the final assembly, ensuring stringent quality control. This process is designed to maximize the efficiency, reduce waste, and uphold the highest standards of production quality, resulting in a reliable Polystyrene Tool that meets diverse client needs.

Product Application Scenarios

The EPS Fish Box Mould is predominantly utilized in the production of insulating and protective packaging solutions, essential for the seafood industry. Its applications extend to other industries requiring lightweight, insulated containers, such as agricultural produce transportation and storage. Given its superior insulating properties, EPS is unmatched in maintaining temperature-sensitive goods like fish and seafood, ensuring freshness from point of origin to destination. Moreover, the mould is tailored to produce robust and durable boxes, capable of withstanding external pressures and harsh handling environments. Such versatile applications underscore the mould's role as a vital Polystyrene Tool in industries aiming for efficient, cost-effective, and environmentally conscious packaging solutions.

Product After-Sales Service

We provide comprehensive after-sales support, including installation guidance, operational training, and technical support, ensuring clients can maximize the efficiency of their Polystyrene Tool. Our dedicated service team is available round-the-clock to address any queries or issues, providing swift resolutions to ensure minimal downtime and sustained productivity.

Product Transportation

Our EPS Fish Box Moulds are securely packed in plywood boxes to prevent damage during transit. We coordinate with reliable logistics partners to facilitate prompt and safe delivery, offering tracking information to keep the client informed throughout the shipping process.

Product Advantages

- High-quality aluminum construction ensures durability.

- Precision CNC machining for accurate mould size.

- Teflon coating facilitates easy demoulding and longevity.

- Customizable to meet specific client needs.

- Efficient design reduces production costs and waste.

Product FAQ

- What materials are used in the mould? Our moulds are crafted from premium aluminum alloy, ensuring durability and precision.

- How accurate are the mould sizes? All mould sizes are precise, with tolerances maintained within 1mm through CNC machining.

- Can you custom design moulds? Yes, we offer custom design services to meet specific client requirements, leveraging our expert engineering team.

- What are the typical delivery times? Delivery times range from 25 to 40 days, depending on the complexity of the order and customization needs.

- How do you ensure quality control? We implement strict quality control at every stage of the production process, from patterning to final assembly, ensuring top-notch product standards.

- Are the moulds easy to maintain? Yes, the Teflon coating facilitates easy demoulding and maintenance, enhancing mould longevity.

- What industries commonly use this mould? Our EPS Fish Box Moulds are widely used in the seafood packaging industry, agriculture, and other sectors requiring insulated containers.

- Do you offer after-sales support? Yes, we provide full after-sales support, including installation guidance and technical assistance.

- Is there a warranty on the mould? Our moulds come with a warranty, details of which can be discussed at the time of purchase.

- How is the mould transported? Moulds are packed in sturdy plywood boxes and transported via trusted logistics partners, ensuring safe delivery.

Product Hot Topics

- Innovation in Polystyrene Tool Design - Discussing our latest advancements in mould design that enhance efficiency and reduce environmental impact.

- Environmental Impact of Polystyrene - An exploration of the sustainability challenges associated with polystyrene and initiatives aimed at mitigating its impact.

- Recycling Polystyrene: Opportunities and Challenges - Examining current technologies and future prospects for recycling EPS products.

- Applications of EPS in Modern Industries - A comprehensive overview of how EPS moulds are integral to diverse industrial applications.

- Efficiency in EPS Mould Production - A deep dive into how our manufacturing processes ensure high-quality, precision moulds.

- Customization in EPS Mould Design - Highlighting our capabilities in providing bespoke solutions to meet specific client needs.

- Global Market Trends in EPS Moulds - Analyzing current and future trends shaping the demand for EPS moulds worldwide.

- Customer Success Stories - Showcasing how our EPS moulds have enabled clients to achieve remarkable production efficiencies.

- Future of Polystyrene Tools - Predicting future developments in polystyrene technology and their potential impacts.

- Collaborations for Sustainable Solutions - Discussing how partnerships can drive innovation in sustainable EPS moulds and products.

Image Description

There is no picture description for this product