Wholesale Expanded Polystyrene Blocks

Product Main Parameters

| Item | Specification |

|---|---|

| Material | Expanded Polystyrene |

| Density | 10-30 kg/m³ |

| Thermal Conductivity | 0.03-0.04 W/m·K |

| Size | Customizable |

| Color | White |

Common Product Specifications

| Application | Specification |

|---|---|

| Construction | Insulated Concrete Forms, Wall Insulation, Roof Insulation |

| Packaging | Protective Packaging for Electronics, Appliances |

| Crafts & Modeling | Prototypes, Models, Designs |

| Marine Industry | Flotation Devices, Buoys |

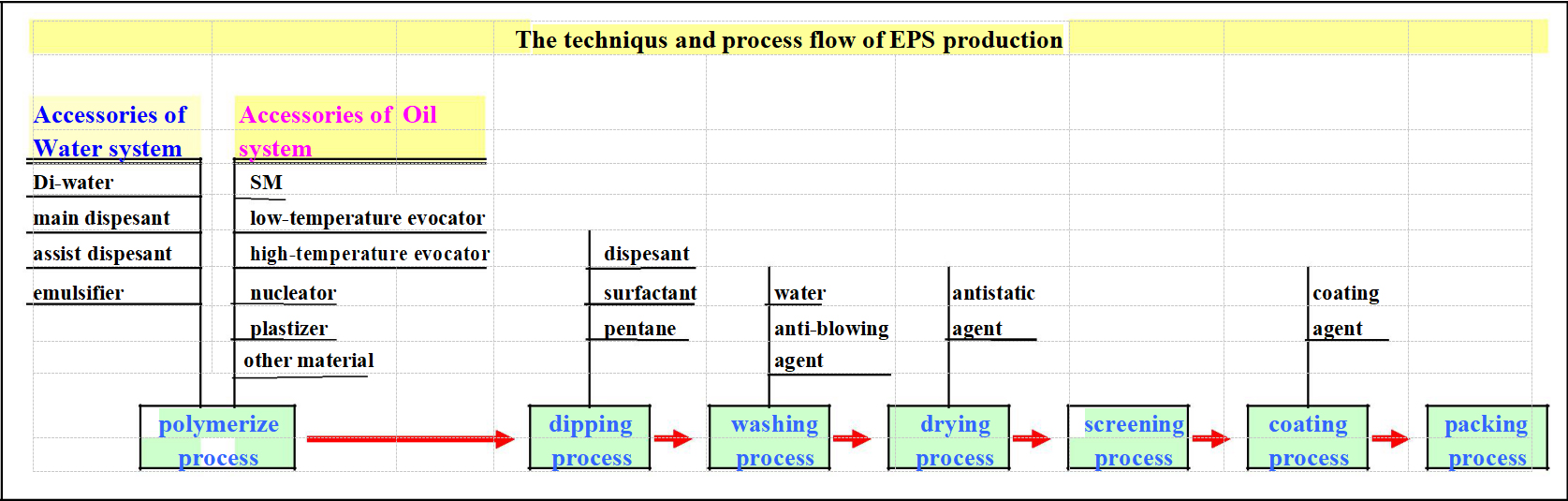

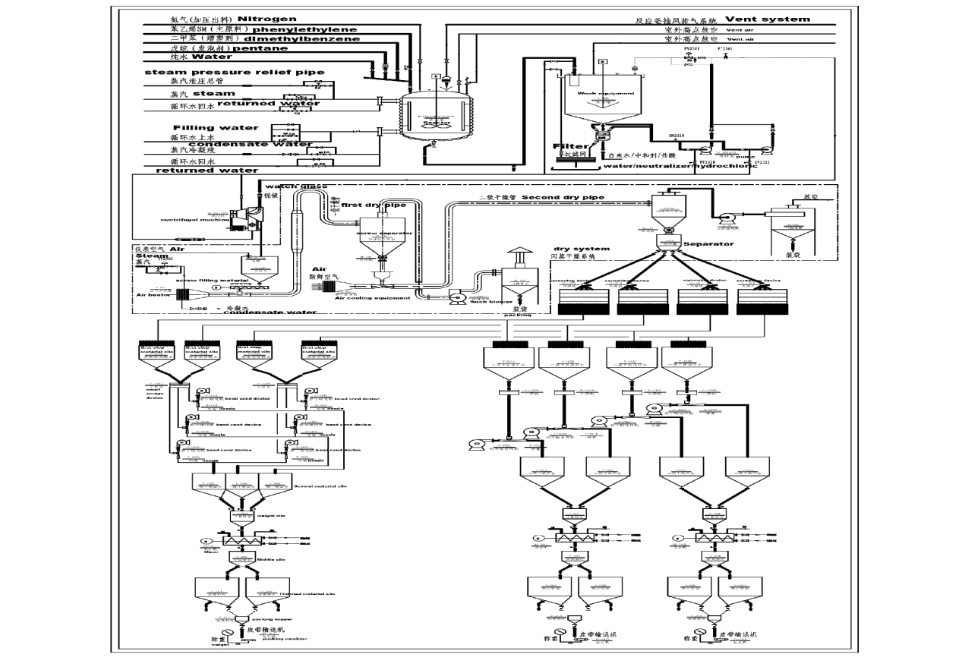

Product Manufacturing Process

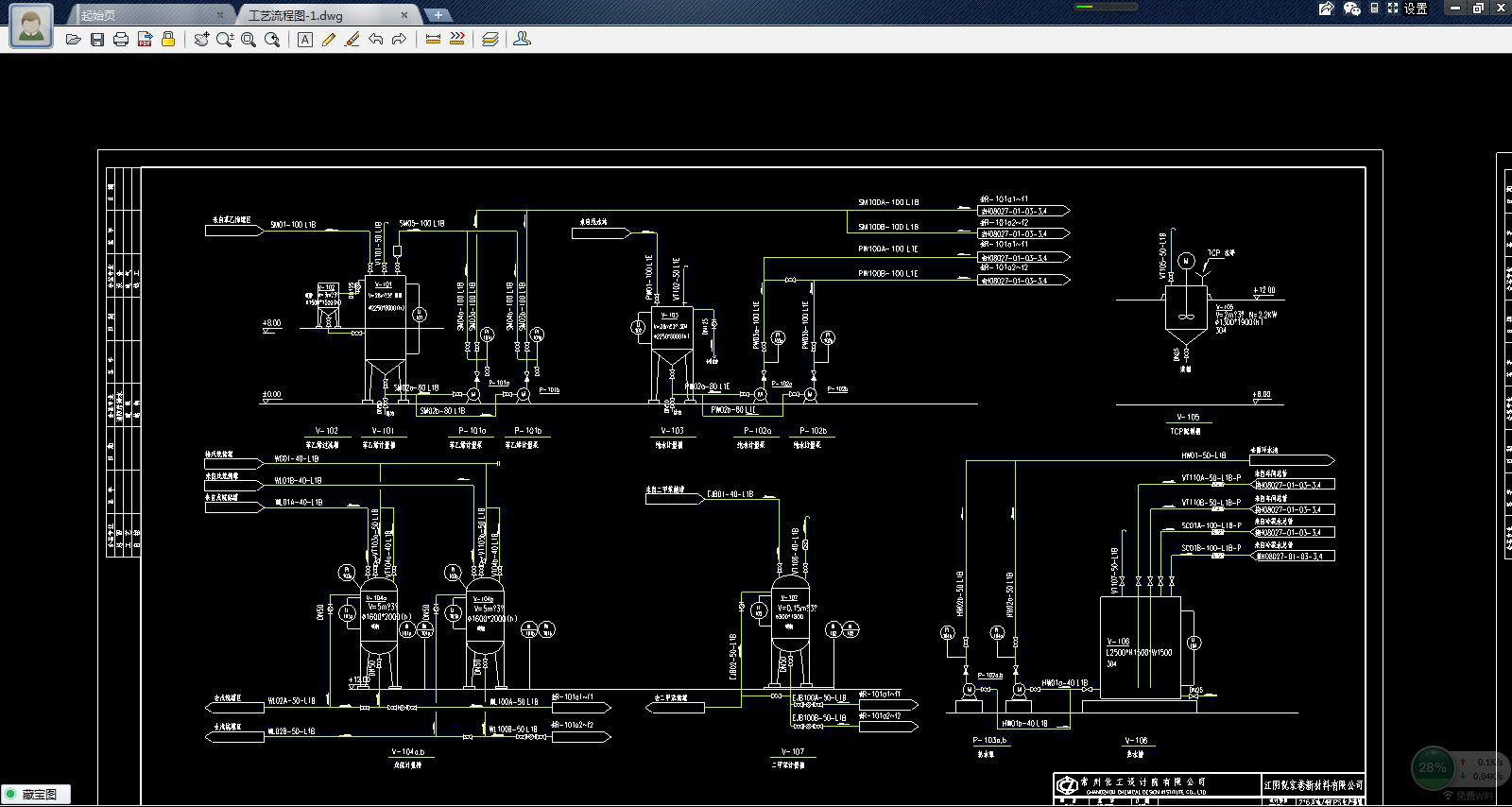

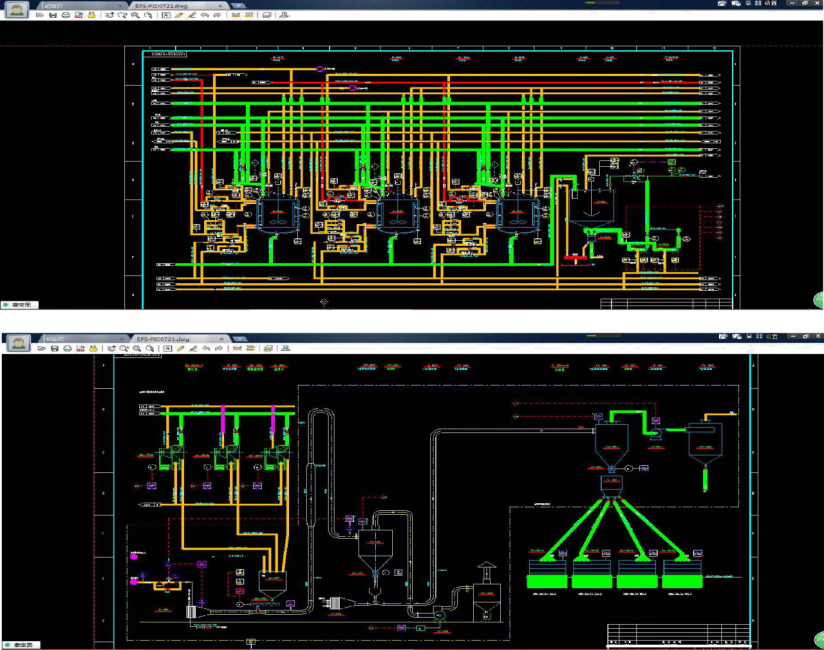

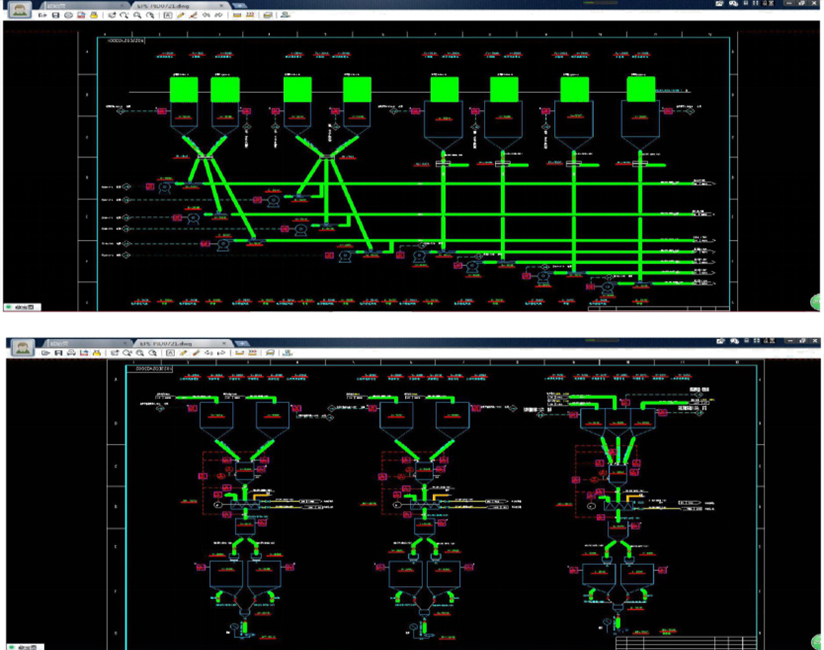

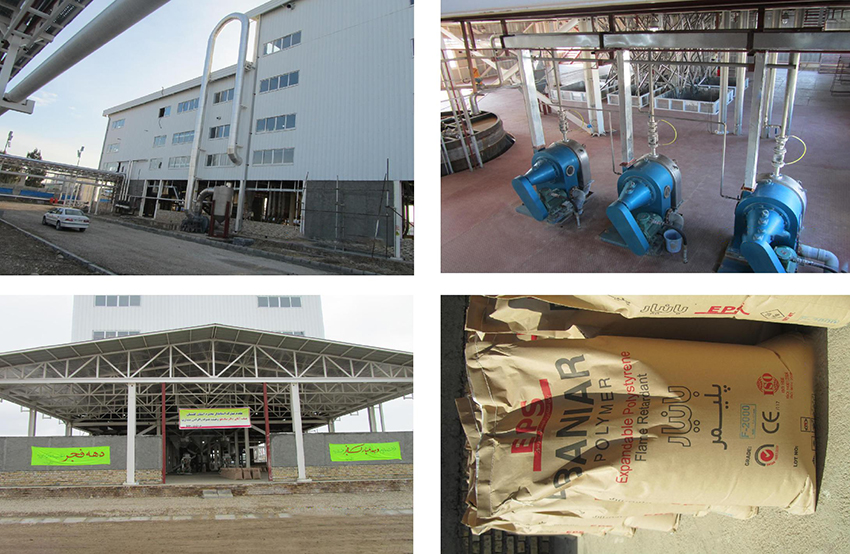

The manufacturing process for wholesale Expanded Polystyrene Blocks involves multiple steps. Initially, polystyrene beads are mixed with a blowing agent like pentane gas and subjected to steam heating. This heat causes the beads to soften and expand significantly. After this initial expansion, the beads are stabilized and subjected to a second heating phase to fuse them into large, solid blocks.

These blocks are lightweight, comprising over 90% air while retaining impressive strength and stability. The entire process is monitored carefully to ensure consistent quality and size of the beads. Advanced technologies like DCS systems are employed for temperature and pressure control to ensure safe and efficient production.

Product Application Scenarios

Wholesale Expanded Polystyrene Blocks find diverse applications across various industries due to their unique properties:

Construction: EPS blocks are used in insulated concrete forms (ICFs) to improve building energy efficiency. They also serve as wall and roof insulation, providing excellent thermal resistance.

Packaging: These blocks are ideal for protective packaging of electronics, appliances, and fragile items due to their lightweight and shock-absorbing properties.

Crafts & Modeling: Artists and hobbyists favor EPS blocks for creating prototypes, models, and intricate designs, thanks to their ease of cutting and shaping.

Marine Industry: EPS blocks are used in flotation devices like life vests and buoys because of their buoyancy and water resistance.

Product After-sales Service

We provide comprehensive after-sales service for our wholesale Expanded Polystyrene Blocks. Our support includes technical assistance, replacement of defective products, and guidance on recycling practices. Customers can reach out through our dedicated helpline or email support for prompt resolutions.

Product Transportation

Our wholesale Expanded Polystyrene Blocks are packaged securely to prevent damage during transportation. We collaborate with reliable logistics partners to ensure timely delivery. Custom packaging options are available based on client requirements.

Product Advantages

- Lightweight and easy to handle

- Excellent thermal insulation properties

- High moisture resistance

- Durable and strong

- Versatile and customizable for various applications

- Recyclable, reducing environmental impact

Product FAQ

1. What are the primary uses of Expanded Polystyrene Blocks?

EPS blocks are mainly used in construction for insulation, in packaging for protective purposes, in crafts and modeling for creating prototypes and designs, and in the marine industry for flotation devices.

2. Are these blocks available for wholesale?

Yes, we offer wholesale Expanded Polystyrene Blocks for bulk purchases. Contact us for pricing and minimum order quantities.

3. How are EPS blocks manufactured?

They are made by expanding polystyrene beads with steam heating, followed by stabilization and a second heating phase to fuse them into solid blocks.

4. Can I customize the size of the EPS blocks?

Yes, we offer customizable sizes to meet specific client requirements.

5. What are the environmental considerations for EPS blocks?

EPS blocks are recyclable, and efforts are being made to incorporate recycled materials into new products to reduce environmental impact.

6. What is the thermal conductivity of EPS blocks?

The thermal conductivity of EPS blocks ranges from 0.03 to 0.04 W/m·K.

7. How durable are EPS blocks?

Despite their lightweight nature, EPS blocks are strong and resistant to compression.

8. Do you offer technical support for setting up an EPS production line?

Yes, we provide comprehensive technical support, including design assistance and on-site supervision for setting up EPS production lines.

9. Are EPS blocks moisture-resistant?

Yes, EPS blocks are highly resistant to water and moisture, making them suitable for various applications.

10. What measures are in place for quality control?

We implement strict quality control measures, including DCS systems for temperature and pressure monitoring, to ensure consistency and quality of our products.

Product Hot Topics

1. The Growing Demand for EPS Blocks in Construction

The construction industry is increasingly turning to wholesale Expanded Polystyrene Blocks for their excellent thermal insulation and lightweight properties. These blocks contribute to energy-efficient buildings, helping to reduce overall energy consumption and costs. As sustainable construction practices gain momentum, the demand for EPS blocks is expected to rise, making them a popular choice for new builds and retrofitting projects.

2. Innovations in EPS Block Manufacturing

Recent advancements in manufacturing technology have improved the quality and versatility of Expanded Polystyrene Blocks. Innovations such as automated control systems for temperature and pressure ensure consistent production, while new formulations enhance the material’s insulating properties. These technological strides are enabling manufacturers to meet the growing demand for high-performance EPS blocks in various industries.

3. Environmental Impact and Recycling of EPS Blocks

Wholesale Expanded Polystyrene Blocks offer numerous benefits, but their environmental impact is a concern. Recycling initiatives are gaining traction, aiming to reduce plastic waste by incorporating recycled EPS into new products. Increased awareness and better recycling infrastructure are key to mitigating the environmental footprint of EPS blocks. Companies are also exploring biodegradable alternatives to address these concerns.

4. The Role of EPS Blocks in Sustainable Packaging

EPS blocks are widely used in packaging due to their lightweight and shock-absorbing properties. As the demand for sustainable packaging solutions grows, EPS blocks are being re-evaluated for their recyclability and environmental impact. By incorporating recycled materials and improving recycling processes, the packaging industry is working towards more eco-friendly solutions without compromising on protection and durability.

5. Customization Options for EPS Blocks

One of the key advantages of wholesale Expanded Polystyrene Blocks is their versatility. Customers can customize the size, density, and shape to meet specific project requirements. This flexibility makes EPS blocks an attractive option for a wide range of applications, from construction to crafts and modeling. As demand for customized solutions grows, manufacturers are expanding their offerings to cater to diverse needs.

6. Importance of Quality Control in EPS Block Production

Maintaining high standards of quality control is crucial in the production of Expanded Polystyrene Blocks. Advanced systems like DCS ensure precise temperature and pressure control during manufacturing, resulting in consistent and high-quality products. Rigorous quality checks and adherence to industry standards are essential to meet the expectations of clients and ensure the durability and performance of EPS blocks.

7. Applications of EPS Blocks in the Marine Industry

The marine industry utilizes EPS blocks for flotation devices such as life vests and buoys due to their buoyant and water-resistant properties. The lightweight nature of EPS blocks ensures they provide effective flotation without adding significant weight. As safety regulations and standards evolve, the marine industry continues to rely on high-quality EPS blocks for reliable and durable flotation solutions.

8. Challenges and Solutions in EPS Block Transportation

Transporting Expanded Polystyrene Blocks presents challenges due to their lightweight yet bulky nature. Efficient packaging and logistics strategies are essential to optimize space and ensure safe delivery. Manufacturers are working on innovative packaging solutions and collaborating with logistics partners to overcome these challenges and deliver EPS blocks to clients in pristine condition.

9. Future Trends in EPS Block Usage

The future of wholesale Expanded Polystyrene Blocks looks promising, with increasing applications in various industries. As sustainability and energy efficiency become top priorities, the demand for EPS blocks in construction and packaging is expected to grow. Advancements in recycling and manufacturing technologies will further enhance the performance and environmental credentials of EPS blocks, solidifying their place in the market.

10. The Economic Benefits of Using EPS Blocks

Using wholesale Expanded Polystyrene Blocks offers significant economic benefits. Their lightweight nature reduces transportation costs, while their excellent insulating properties contribute to energy savings in buildings. The durability and versatility of EPS blocks also minimize replacement and maintenance costs. These economic advantages make EPS blocks an attractive option for businesses looking to optimize costs without compromising on quality and performance.

Image Description