Wholesale EPS Mould Manufacturer for Fish Box

Product Main Parameters

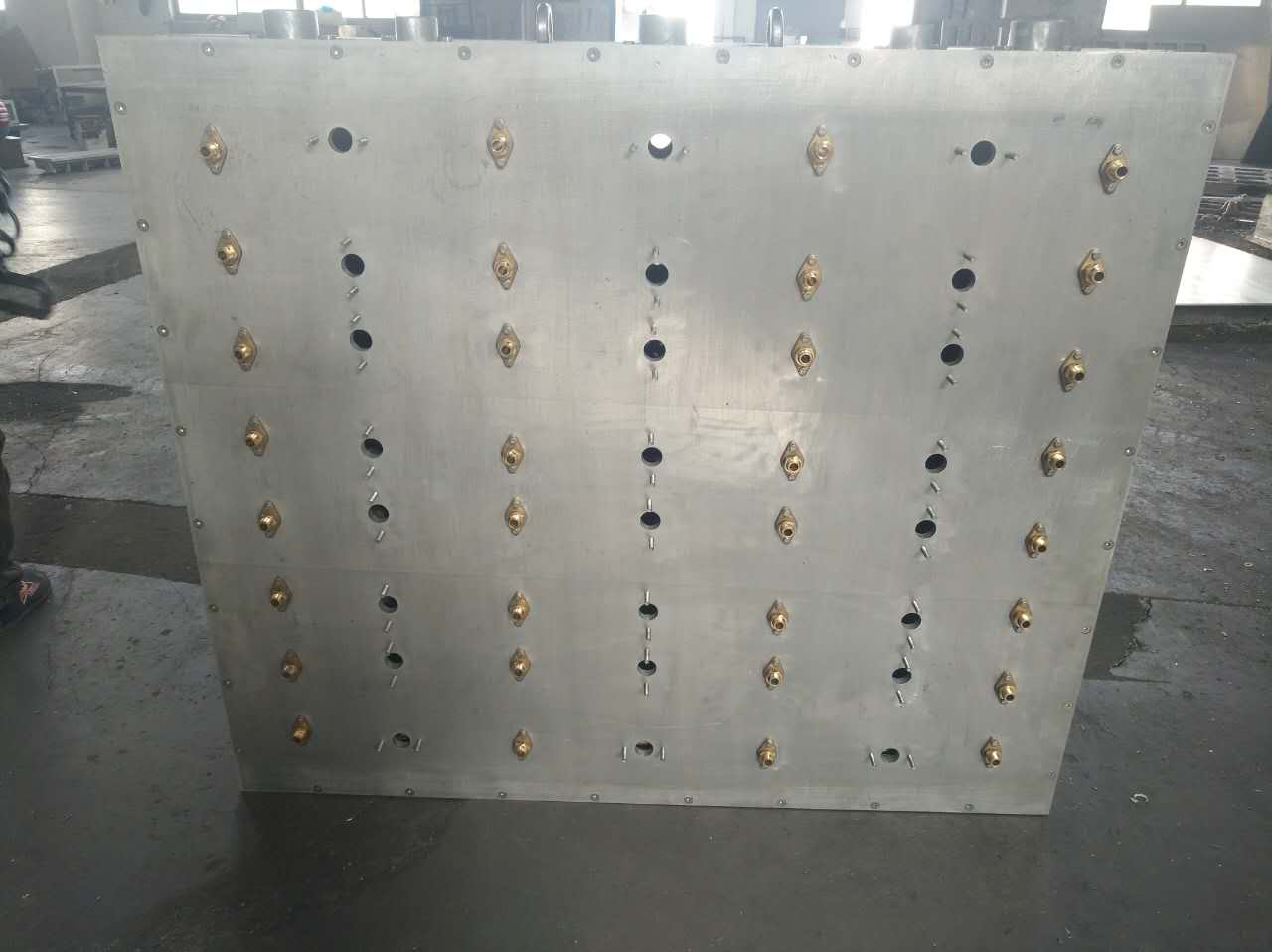

| Steam Chamber | 1200*1000mm, 1400*1200mm, 1600*1350mm, 1750*1450mm |

|---|---|

| Mould Size | 1120*920mm, 1320*1120mm, 1520*1270mm, 1670*1370mm |

| Patterning | Wood or PU by CNC |

| Machining | Fully CNC |

| Aluminum Plate Thickness | 15mm |

| Packing | Plywood box |

| Delivery Time | 25~40 days |

Common Product Specifications

| Material | High-quality aluminum |

|---|---|

| Tolerance | Within 1mm |

| Coating | Teflon for easy demoulding |

Product Manufacturing Process

The production of EPS molds involves a detailed engineering and design process. Initially, the desired product is conceptualized and designed using CAD software to ensure meticulous precision. Important factors like material flow and cooling rates are considered during the design phase. Once the design is finalized, CNC machines create the molds from high-quality aluminum blocks, ensuring accuracy. After fabrication, the molds are assembled and tested rigorously, undergoing trial runs to guarantee they meet industry standards. These processes ensure the molds are durable, efficient, and capable of producing precise EPS products.

Product Application Scenarios

EPS molds are versatile and widely used in various industries. In construction, they're essential for producing insulation panels and concrete forming blocks. The packaging industry relies on EPS molds for creating protective packaging materials, crucial for safeguarding electronics and other fragile goods. In consumer goods, EPS molds are used to produce items like coolers and lightweight furniture. Their adaptability and precision make them indispensable across these sectors, playing a critical role in ensuring product quality and consistency.

Product After-sales Service

Our after-sales service includes comprehensive support, offering maintenance and repair services to ensure your EPS molds continue operating at peak efficiency. Our experienced technicians are available for troubleshooting and providing technical guidance. We also offer a warranty period during which our team will assist in addressing any manufacturing defects or issues promptly.

Product Transportation

The EPS molds are securely packed in plywood boxes to ensure safe transportation. We collaborate with reliable logistics partners to ensure timely and damage-free delivery, providing tracking information for your convenience.

Product Advantages

- High precision due to CNC machining

- Durable, made from first-class aluminum

- Quick delivery and rigorous quality checks

- Designed by industry experts with over 20 years of experience

Product FAQ

- Q1: What material is used for the EPS molds?

A1: We use high-quality aluminum ingots to craft our molds, ensuring durability and a long lifespan. Our molds are designed to withstand the rigors of repeated use, making them ideal for various industrial applications. - Q2: How precise are the EPS molds manufactured?

A2: Our EPS molds are fully processed using CNC machines, achieving a tolerance within 1mm. This precision ensures that the final EPS products meet exact specifications and quality standards required by different industries. - Q3: Can the EPS molds be customized according to specific requirements?

A3: Yes, as a wholesale EPS mould manufacturer, we can design custom molds to meet specific client needs. Our experienced engineers convert customer samples into detailed CAD or 3D designs for tailored production. - Q4: What is the estimated delivery time for EPS molds?

A4: The delivery time is typically between 25 to 40 days, depending on the complexity of the mold design and the scale of production. We strive to meet client deadlines efficiently. - Q5: Are your molds compatible with EPS machines from different countries?

A5: Yes, we have extensive experience crafting molds for Chinese, German, Japanese, Korean, and Jordanian EPS machines, ensuring compatibility across various systems. - Q6: What is the packing method for shipping EPS molds?

A6: We pack our molds in durable plywood boxes to protect them during transit. This method safeguards against damage, ensuring safe delivery to your location. - Q7: Do you provide any warranty on the EPS molds?

A7: Yes, we provide a warranty period during which we cover manufacturing defects. Our after-sales service team is available for any required maintenance or support. - Q8: How do you ensure the quality of your EPS molds?

A8: Our quality control measures are stringent, covering every stage from patterning, casting, machining, to assembling. Each mold undergoes rigorous testing for consistent high-quality output. - Q9: Can you help design a new EPS factory setup?

A9: Yes, our experienced technical team can assist in designing new EPS factory setups, providing comprehensive turn-key solutions to enhance production efficiency and capacity. - Q10: What are the environmental considerations for EPS mold manufacturing?

A10: We are committed to sustainable practices by exploring recycled materials and enhancing energy efficiency in our operations to minimize environmental impact while maintaining high production standards.

Product Hot Topics

- How CNC Precision Enhances EPS Mould Manufacturing

The integration of CNC machines in EPS mould manufacturing significantly boosts precision and efficiency. CNC machining allows for exact control over the mold creation process, reducing human error and ensuring that every mold adheres to tight tolerance levels, typically within 1mm. This precision is vital for producing complex EPS products that require exact dimensions and quality. The advanced technology of CNC machines also speeds up production timelines, ensuring rapid delivery without compromising on quality. As a wholesale EPS mould manufacturer, leveraging CNC precision is key to maintaining competitive advantage and meeting client expectations in diverse industrial sectors.

- The Role of Aluminum in Durable EPS Moulds

Aluminum is a preferred material in the manufacturing of EPS molds due to its durability and lightweight properties. Its excellent thermal conductivity and resistance to corrosion make it ideal for withstanding the repetitive heating and cooling cycles during EPS production. Furthermore, aluminum molds are easier to handle, reducing labor costs and improving operational efficiency. As a wholesale EPS mould manufacturer, using high-quality aluminum ensures that our molds last longer and deliver consistent results under demanding industrial conditions. Additionally, the recyclability of aluminum aligns with sustainable manufacturing practices, addressing growing environmental concerns.

- Environmental Sustainability in EPS Mould Manufacturing

With increasing scrutiny on environmental impacts, EPS mould manufacturers are innovating towards more sustainable practices. This includes utilizing recycled materials in mold production and investing in energy-efficient machinery to minimize carbon footprints. Additionally, developing biodegradable alternatives to traditional EPS products are gaining traction. Such initiatives not only reduce waste but also appeal to eco-conscious clients, ensuring a balance between industrial demands and ecological responsibility. As a wholesale EPS mould manufacturer, we remain committed to these practices, helping to pave the way for a greener future in manufacturing.

- Custom EPS Moulds: Meeting Diverse Industry Needs

The ability to create custom EPS molds is crucial in addressing the specific needs of diverse industries. From construction to consumer goods, each sector demands unique mold designs tailored to their applications. Customization involves converting client samples into precise CAD or 3D models, ensuring that every mold meets exact specifications. This capability enhances production versatility and efficiency, enabling businesses to innovate and adapt to market trends. As a leading wholesale EPS mould manufacturer, we prioritize customization to provide solutions that align with our clients' specific operational requirements and strategic goals.

- Optimizing Production with EPS Mould Maintenance

Regular maintenance of EPS molds is essential for sustaining production efficiency and prolonging mold lifespan. Routine checks identify wear and tear that could affect the accuracy of the final EPS product. As a wholesale EPS mould manufacturer, we recommend a proactive approach to mold maintenance, including cleaning, lubrication, and periodic inspections. This practice not only prevents costly downtime but also ensures consistent quality in every production batch, upholding the high standards of the EPS industry. Our after-sales service includes comprehensive maintenance support to aid businesses in optimizing their EPS production operations.

- The Impact of Quality Control in EPS Mould Production

Quality control is a critical aspect of EPS mould manufacturing, ensuring that each mold meets rigorous industry standards. This involves thorough testing and inspection at each stage of production, from initial design to final assembly. As a wholesale EPS mould manufacturer, our quality control measures include trial runs and adjustments to refine mold performance, guaranteeing the reliability and precision of each product. Stringent quality assurance not only boosts client confidence but also minimizes the risk of defects in the final EPS products, leading to improved customer satisfaction and brand loyalty.

- Innovations in EPS Mould Heat Transfer Efficiency

Enhancing heat transfer efficiency in EPS molds can lead to significant improvements in production speed and energy consumption. This involves optimizing the mold design to facilitate even heating and cooling, reducing cycle times and increasing throughput. Advanced materials and coatings, such as Teflon, play a role in improving the release of EPS products from molds, further enhancing efficiency. As a wholesale EPS mould manufacturer, we continuously explore innovative solutions to optimize heat transfer, aligning our production processes with modern technological advancements to deliver superior mold performance.

- Challenges and Solutions in EPS Mould Customization

Customizing EPS molds presents challenges such as ensuring compatibility with existing production systems and meeting specific client design requirements. These challenges require a thorough understanding of different materials, precise CAD skills, and advanced machining capabilities. As a wholesale EPS mould manufacturer, we address these challenges by leveraging our extensive industry experience and expertise. Our team collaborates closely with clients to tailor molds to their needs, overcoming obstacles through innovative engineering solutions and robust quality assurance practices, ensuring that customization enhances rather than hinders production processes.

- The Future of EPS Mould Manufacturing

Advancements in technology and materials science are shaping the future of EPS mould manufacturing, with a focus on automation, efficiency, and sustainability. Emerging technologies such as AI-driven design and 3D printing could revolutionize mold production, offering new levels of precision and customization. As environmental considerations continue to impact manufacturing, sustainable practices and material innovation will play a central role. As a forward-thinking wholesale EPS mould manufacturer, we remain at the forefront of these trends, investing in research and development to provide cutting-edge solutions that meet evolving industry needs.

- Understanding EPS Mould Lifecycle Management

Managing the lifecycle of EPS molds involves strategic planning from design to disposal, ensuring each mold is utilized efficiently and sustainably. This includes regular maintenance schedules, performance monitoring, and optimization of operational practices. At the end of a mold's lifecycle, recycling or repurposing its materials can contribute to sustainable manufacturing goals. As a wholesale EPS mould manufacturer, we advocate for comprehensive lifecycle management strategies that enhance mold longevity, reduce environmental impact, and support businesses in maintaining profitable and responsible production frameworks.

Image Description

There is no picture description for this product