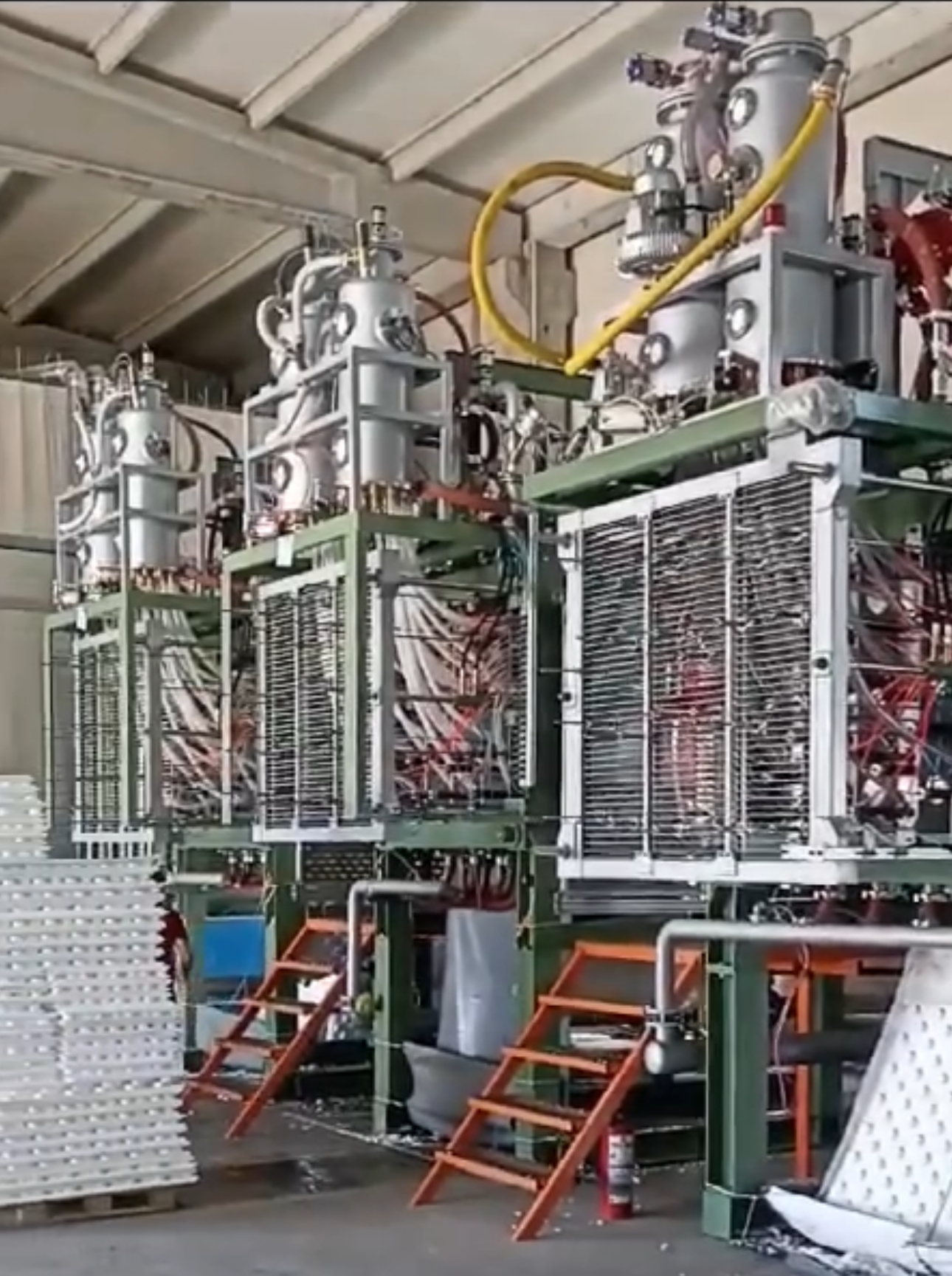

Wholesale EPS Injection Molding Machine for Various Applications

Product Main Parameters

| Parameter | Details |

|---|---|

| Mould Dimension | 2200*1650 mm |

| Max Product Dimension | 2050*1400*400 mm |

| Steam Entry | 5’’(DN125) |

| Consumption | 9~11 Kg/cycle |

| Pressure | 0.4~0.6 Mpa |

| Cooling Water Entry | 4’’(DN100) |

| Weight | 8200 Kg |

Common Product Specifications

| Specification | Details |

|---|---|

| Stroke | 150~1500 mm |

| Steam Pressure | 3~4bar |

| Power | 17.2 Kw |

| Overall Dimension | 5100*2460*5500 mm |

Product Manufacturing Process

The EPS Injection Molding Machine employs a series of steps to produce high-quality EPS products. Initially, raw EPS beads undergo pre-expansion through heat application. This step is crucial for achieving desired bead size and density, which are critical for durability and insulation properties. Afterward, the beads are conditioned for equilibrium. The beads are then injected into the mold, followed by heating, fusing, cooling, and ejection—each step precisely controlled to ensure product integrity.

Product Application Scenarios

EPS Injection Molding is employed across various sectors due to its lightweight, thermal insulation, and robust structural qualities. It is ubiquitously used in the packaging industry for crafting protective packaging for delicate items like electronics and appliances. In the construction sector, its insulation properties are leveraged for energy-efficient building solutions. Additionally, due to its adaptability, it's also used in manufacturing educational materials and recreational products.

Product After-sales Service

We offer a comprehensive after-sales service for our wholesale EPS Injection Molding Machine, including technical support, maintenance, and parts replacement. Our technical team is available to address any operational issues and ensure maximum uptime. Clients receive documentation detailing machine operation and troubleshooting steps.

Product Transportation

Our EPS Injection Molding Machines are shipped using our trusted logistic partners ensuring safe and timely delivery. We offer global shipping and coordinate with clients to ensure compliance with local import regulations and paperwork.

Product Advantages

- Efficient and Fast Production

- Reduced Energy Consumption

- Customizable for Various Product Shapes

- Low Maintenance with High-Quality Components

- Flexible for Multiple Industrial Applications

Product FAQ

- How does the machine improve efficiency? Our EPS Injection Molding Machine reduces cycle time by 25% and energy consumption by 25%, enhancing overall production efficiency.

- What are the maintenance requirements? Regular maintenance includes checking hydraulic and steam systems, cleaning filters, and ensuring proper lubrication to prevent wear and tear.

- Can the machine handle multiple product types? Yes, the machine supports various molds for different EPS product shapes, from packaging to construction materials.

- Is technical support available? Yes, our team provides ongoing technical support and assistance for troubleshooting and operational guidance.

- What is the typical lifespan of the machine? With proper maintenance, the machine can last over a decade, supported by durable steel plates and renowned components.

- Are there any environmental concerns? While EPS is not biodegradable, efforts in recycling processes are underway to mitigate environmental impact.

- What are the shipping details? Machines are shipped globally with our trusted logistics partners, ensuring secure and timely delivery.

- Can surplus EPS be recycled? Yes, recycling options exist, and we encourage environmentally responsible disposal of EPS products.

- Is training available for machine operation? Yes, we offer training workshops and detailed user manuals for operators to ensure safe and efficient usage.

- What quality standards does the machine adhere to? The machine is manufactured adhering to international quality standards, using high-grade components for reliability.

Product Hot Topics

- Innovations in EPS Molding Technology Advancements in EPS Injection Molding Machines have led to greater efficiency and customization options, facilitating diverse industrial applications worldwide.

- Environmental Impact of EPS While EPS products are not biodegradable, the recycling initiatives and technologies are rapidly evolving to manage the environmental footprint effectively.

- EPS vs. Traditional Insulation Materials EPS offers superior thermal insulation compared to traditional alternatives, making it a preferred choice in the construction industry for energy-efficient buildings.

- The Role of EPS Molding Machines in Packaging Due to its shock-absorbing capabilities, EPS remains a crucial material in the packaging industry, protecting delicate items during transportation.

- Energy Efficiency in EPS Production The latest EPS Injection Molding Machines boast reduced energy consumption, aligning with global energy-saving initiatives and cost reduction.

- Global Market Trends for EPS Products The demand for EPS products is on the rise, with increased applications across diverse sectors such as automotive, electronics, and construction.

- Technological Advancements in EPS Molding Recent innovations in EPS Molding Technology have paved the way for faster production cycles, higher product quality, and better material utilization.

- Impact of EPS on Modern Construction The adaptability and insulation properties of EPS position it as a key material in sustainable and energy-efficient building designs.

- Challenges in EPS Waste Management Addressing the disposal and recycling of EPS waste remains a challenge, though strides are being made in developing effective recycling methods.

- Future Prospects of EPS Molding Technology With ongoing research and innovation, EPS Molding Technology is poised for further advancements, promising enhanced versatility and efficiency.

Image Description