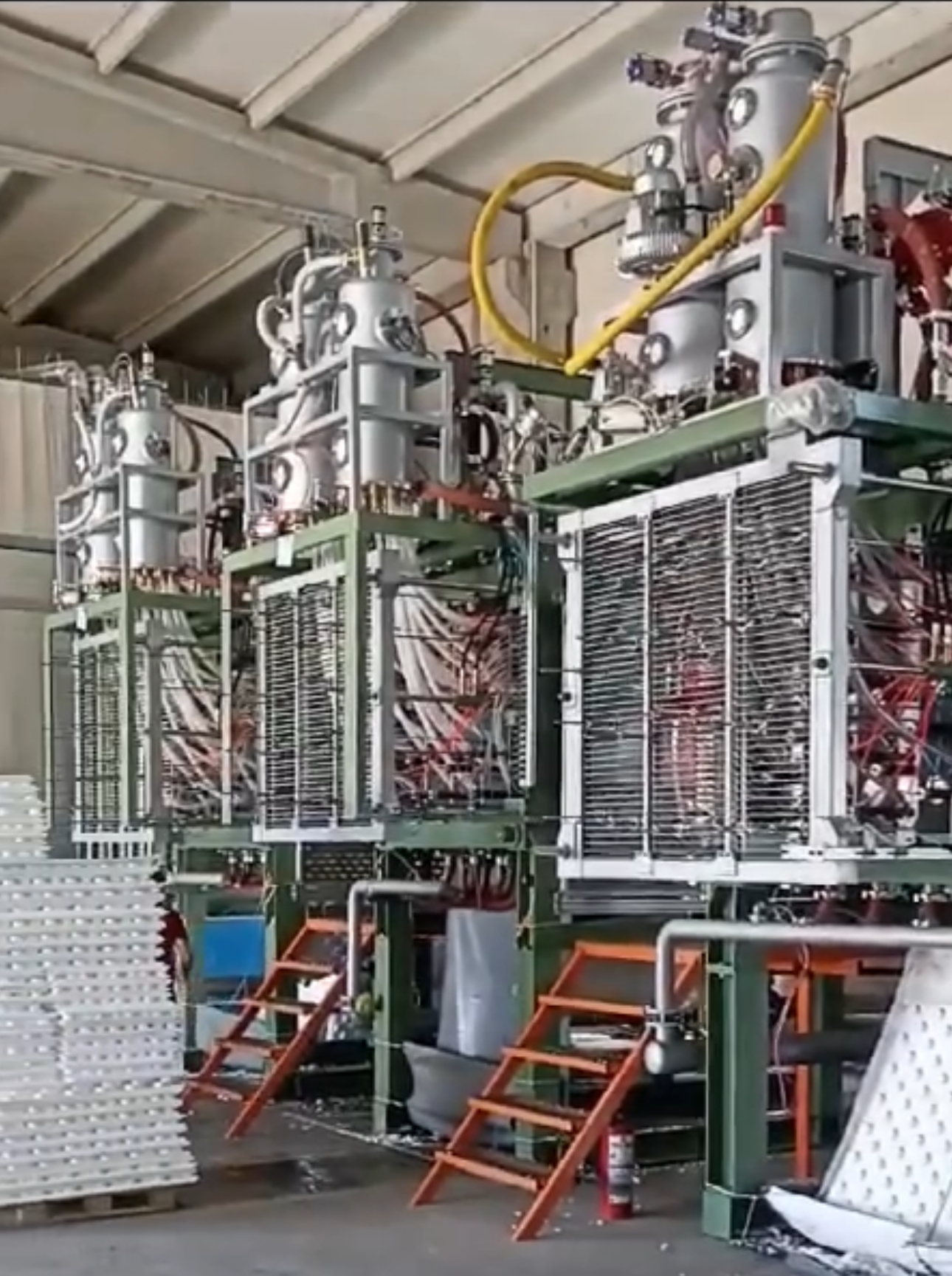

Wholesale CNC Styrofoam Vacuum Casting Machine

Product Main Parameters

| Item | Unit | PSZ-1200E | PSZ-2200E |

|---|---|---|---|

| Mould Dimension | mm | 1200*1000 | 2200*1650 |

| Max Product Dimension | mm | 1000*800*400 | 2050*1400*400 |

| Steam Consumption | Kg/cycle | 4~7 | 9~11 |

| Connect Load/Power | Kw | 9 | 17.2 |

Common Product Specifications

| Component | Specification |

|---|---|

| Material | Stainless Steel |

| Control System | Mitsubishi PLC |

| Touch Screen | Schneider or Winview |

Product Manufacturing Process

The production process for the CNC Styrofoam machine integrates precision engineering with advanced technology. Firstly, digital designs are created using CAD software, which are converted into G-code for the CNC machine. The machine operates with high precision, consistently reproducing complex shapes and designs. The manufacturing process involves high-grade materials, such as thicker steel plates and a robust hydraulic system, ensuring longevity and reliability. Studies indicate that the adoption of CNC technology in Styrofoam machining significantly reduces waste and enhances efficiency, especially in applications requiring detailed artistry and accuracy.

Product Application Scenarios

The CNC Styrofoam machine has versatile application scenarios, including packaging, construction, and creative industries. In packaging, it efficiently produces protective elements such as electrical packing and vegetable and fruit boxes. For construction, it is used to create components like brick inserts and ICFs. The machine's capability to produce intricate and large-scale designs makes it a favorite in architectural prototyping and model making. Research shows that CNC Styrofoam machines are pivotal in themed environments such as theme parks and exhibitions, where custom, intricate designs are essential.

Product After-Sales Service

- Comprehensive technical support and troubleshooting assistance.

- Regular maintenance services to ensure optimal performance.

- Spare parts availability and replacement guarantees.

Product Transportation

The machine is shipped securely in heavy-duty packaging to prevent damage during transit. We offer global shipping with tracking services, ensuring timely delivery to your location. Local customs and handling fees are considered, and all necessary documentation is provided.

Product Advantages

- High precision and accuracy for consistent production quality.

- Efficiency in design reproduction, suitable for mass production.

- Versatility in creating diverse shapes and sizes for different industries.

- Reduction in material waste contributes to cost-effective operations.

- Low energy consumption.

Product FAQ

- What is the maximum production size?

The machine can produce items with a maximum dimension of 2050*1400*400 mm, allowing for large-scale production suitable for numerous applications.

- How does CNC technology enhance production?

CNC technology ensures precision through computer-controlled cutting and shaping, maintaining consistent quality and accuracy across repeated cycles.

- What are the materials used in construction?

The machine is primarily constructed using stainless steel, known for its durability and resistance to corrosion, providing a long-lasting solution.

- How does the vacuum system work?

The efficient vacuum system reduces cycle time and energy consumption, utilizing a vacuum tank and condenser tank to operate separately for optimal performance.

- Is the machine compatible with other brands?

Yes, the machine is designed to be compatible with multiple EPS moulds, including those from Germany, Korea, and Japan, ensuring versatility.

- What is the energy consumption?

The energy consumption varies by model, with the PSZ-2200E consuming approximately 17.2 Kw, optimized for efficiency and cost-effectiveness.

- What control systems are employed?

The machine uses Mitsubishi PLC for precise control, paired with Schneider or Winview touch screens for user-friendly operation.

- Are there any safety features included?

Yes, the machine incorporates several safety features, including low malfunction rates with high-quality components and a reliable hydraulic system.

- What is the maintenance requirement?

Regular maintenance is recommended for optimal performance. We provide comprehensive support to assist with any technical issues or parts replacements.

- Can it be customized per client requirements?

Absolutely, we offer customization based on client needs. Our technical team works closely to design and implement features as per specific production demands.

Product Hot Topics

- Efficiency in Production

The introduction of wholesale CNC Styrofoam machines is revolutionizing production lines. Their ability to maintain high precision while reducing cycle times and energy consumption is invaluable in both small-scale and large-scale manufacturing. Many companies are adopting these machines for their consistency and reliable output, resulting in significant cost savings and an improved product development cycle.

- Versatile Applications

From packaging to construction, the wholesale CNC Styrofoam machines are being utilized in diverse industries. Their flexibility in design and function allows for seamless integration into existing production lines, enabling manufacturers to expand their capabilities without significant overhaul. This adaptability is a key driver in today's competitive market where customization is crucial.

- Sustainability in Manufacturing

With increasing environmental concerns, the wholesale CNC Styrofoam machines provide a sustainable solution by minimizing waste output. The precision cutting and shaping reduce material excess, aligning with eco-friendly manufacturing goals. As industries move towards sustainability, these machines are gaining recognition for their contribution to greener production practices.

- Technological Advancements

Technology is at the forefront of the wholesale CNC Styrofoam machines' success. Advanced computing and software integration allow for intricate design execution with minimal human error. Businesses leveraging these technological advancements are witnessing a transformation in their operations, resulting in higher quality and efficiency.

- Customization Capabilities

The ability of wholesale CNC Styrofoam machines to customize production lines per client specifications is a significant advantage. Industries requiring specific design and shape outputs benefit from this capability, allowing for tailored solutions that meet exact requirements. This personalized approach is a powerful differentiator in competitive sectors.

Image Description