Wholesale Aluminum EPS Vegetable Box Mould for Efficient Production

Main Technical Parameters

| Steam Chamber Size | 1200*1000mm, 1400*1200mm, 1600*1350mm, 1750*1450mm |

|---|---|

| Mould Size | 1120*920mm, 1320*1120mm, 1520*1270mm, 1670*1370mm |

| Patterning | Wood or PU by CNC |

| Machining | Fully CNC |

| Alu Alloy Plate Thickness | 15mm |

| Packing | Plywood box |

| Delivery | 25~40 days |

Common Product Specifications

| Material | High-quality Aluminum |

|---|---|

| Teflon Coating | Yes |

| Precision | Mould tolerance within 1mm |

| Compatibility | Compatible with various EPS machines |

Product Manufacturing Process

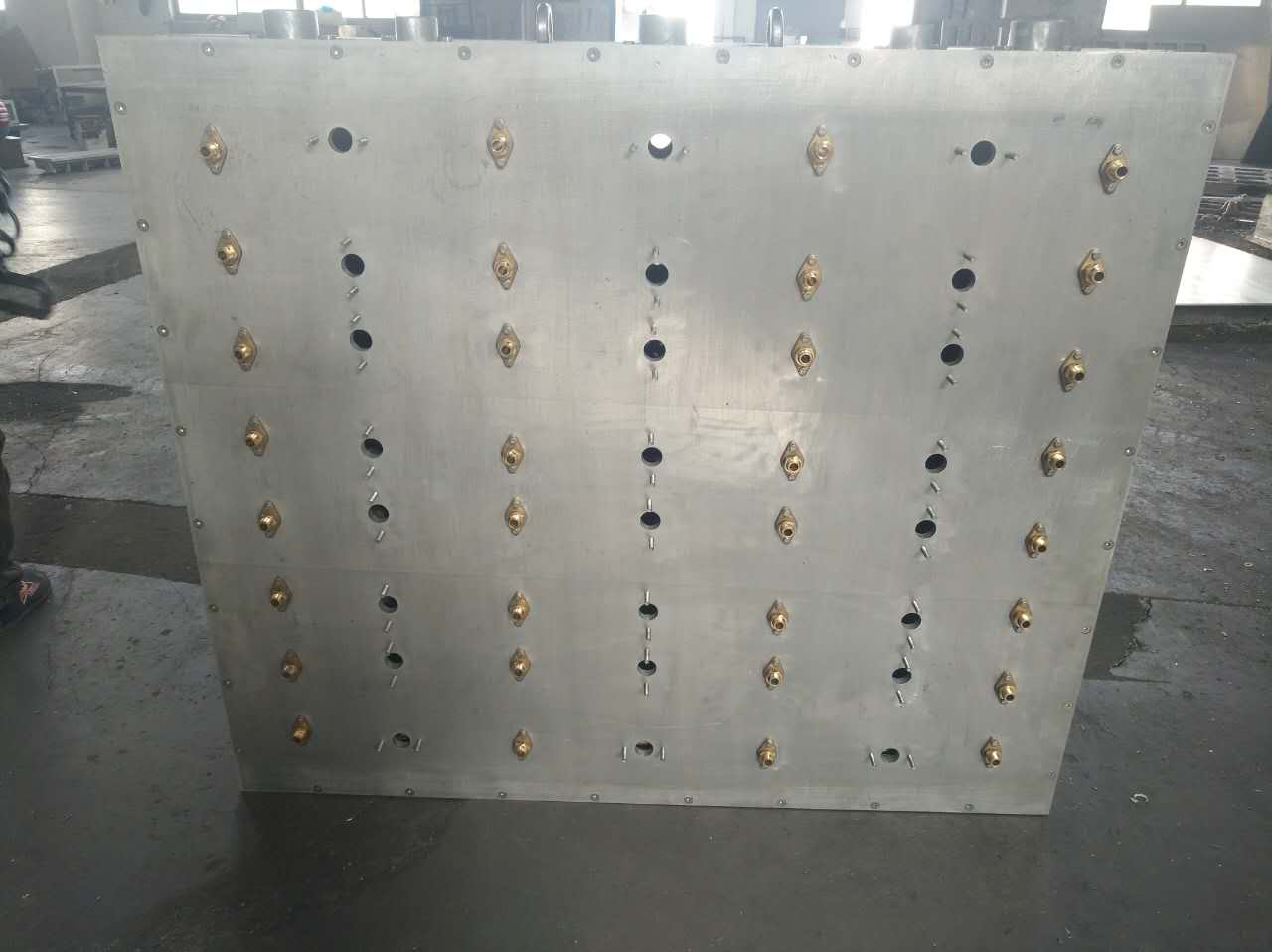

The manufacturing of Aluminum EPS Vegetable Box Moulds involves several key stages: patterning, casting, CNC machining, assembling, and Teflon coating. Initially, detailed CAD designs are developed, outlining the specific dimensions and features of the mould. These designs are then translated into physical patterns using CNC machining, ensuring accuracy and precision. The aluminum is cast and subjected to further CNC machining to achieve the exact shape and dimensions required. The final assembly involves the integration of components such as the core and cavity, including the installation of cooling channels for efficient EPS setting. Teflon coating is applied to facilitate easy demoulding. This process ensures the production of high-quality, durable moulds suitable for efficient EPS box production.

Product Application Scenarios

Aluminum EPS Vegetable Box Moulds are primarily used in the agricultural and packaging sectors. These moulds are essential for producing EPS boxes that are widely utilized in transporting fresh produce, including vegetables and fruits. The insulating properties of EPS boxes help maintain the freshness of perishable goods during transit. Furthermore, their lightweight yet rigid structure offers protection against physical damages, making them ideal for both local and export markets. Retailers also utilize these boxes for storage and display purposes, ensuring that the produce remains fresh and appealing to consumers. The durability and reusability of EPS boxes contribute to cost-effective and sustainable packaging solutions.

Product After-Sales Service

- Comprehensive customer support for installation and operation

- Warranty coverage for manufacturing defects

- Regular maintenance and service plans available

- Replacement parts supplied as needed

Product Transportation

Our Aluminum EPS Vegetable Box Moulds are securely packed in sturdy plywood boxes to ensure safe delivery. We coordinate with reliable shipping partners to ensure timely and efficient transportation to our clients worldwide.

Product Advantages

- Wholesale pricing ensures cost efficiency

- High thermal conductivity for faster production cycles

- Lightweight yet durable construction

- Corrosion-resistant material ensures longevity

- Customizable designs to meet specific client needs

Product FAQ

- What is the minimum order quantity? Our minimum order quantity for wholesale Aluminum EPS Vegetable Box Moulds is generally one unit, as we understand client requirements can vary.

- How do you ensure the quality of your moulds? We have stringent quality checks at each stage of production, including material selection, CNC machining, and final assembly with Teflon coating, to ensure superior quality.

- Can the moulds be customized? Yes, our technical team can customize the moulds according to specific size and design requirements provided by the client.

- What type of EPS machines are compatible with your moulds? Our moulds are compatible with various EPS machines from countries like China, Germany, Korea, and Japan.

- How long does it take to receive an order? Delivery typically takes 25-40 days, depending on the complexity and customization level of the order.

- What are the payment terms? We offer flexible payment terms; please contact our sales team for detailed information.

- What kind of maintenance do the moulds require? Regular cleaning and inspection are recommended to maintain the mould's performance and prolong its lifespan.

- Do you provide technical support after purchase? Yes, we offer comprehensive after-sales support including installation guidance and operational training.

- Are replacement parts available? Replacement parts are available and can be ordered as needed.

- Is there a warranty provided? Yes, we offer a warranty for any manufacturing defects that may arise.

Product Hot Topics

- Advantages of Using Aluminum in EPS Moulds - Aluminum's excellent thermal conductivity is a significant advantage in the production of EPS moulds. This property ensures faster cooling and reduces cycle times, increasing the efficiency of the moulding process. Additionally, aluminum is lightweight, making it easier to handle and maneuver during installation and use. Its resistance to corrosion and ease of machinability further contribute to its suitability for creating intricate and durable moulds.

- The Role of Moulds in the Agricultural Packaging Industry - Moulds are critical in producing the EPS boxes used extensively in the agricultural sector. These boxes offer exceptional protection and insulation for fresh produce, extending shelf life and reducing spoilage. With the growing demand for sustainable and cost-effective packaging solutions, the precision and efficiency of modern mould designs play a pivotal role in meeting industry needs.

- Impact of EPS Packaging on Transportation Costs - The lightweight nature of EPS packaging significantly reduces transportation costs, offering economic benefits for producers and retailers. EPS boxes help lower the overall shipping weight of goods, resulting in reduced fuel consumption and shipping charges, while still providing superior protection for the contents.

- Environmental Considerations of Using EPS - Although EPS is non-biodegradable, its recyclability presents a viable solution for reducing environmental impact. Advancements in recycling technologies are paving the way for more sustainable use of EPS, allowing manufacturers and consumers to capitalize on its benefits while promoting ecological responsibility.

- Customization Trends in EPS Mould Design - As market demands evolve, customization in EPS mould design has become increasingly important. Manufacturers are now offering bespoke solutions tailored to specific client needs, utilizing advanced design and machining techniques to achieve precise and innovative mould configurations.

- Cost Efficiency of Wholesale EPS Mould Purchases - Purchasing EPS moulds wholesale offers significant cost savings for businesses. Large-scale orders reduce the per-unit cost, offering economical advantages without compromising on quality or performance.

- Innovations in EPS Production Techniques - Continuous innovations in EPS production techniques are enhancing the material's performance and application range. From advancements in polymerization processes to improvements in mould design, these innovations are helping meet the ever-growing demands of diverse industries.

- Ensuring Quality in EPS Mould Manufacturing - Quality assurance in EPS mould manufacturing is achieved through rigorous testing and inspection across all production stages. This commitment to quality ensures that moulds deliver consistent performance, reliability, and longevity in various applications.

- Future Prospects of EPS in Agricultural Packaging - The future of EPS in agricultural packaging looks promising with continuous improvements in material properties and mould design. The ongoing focus on sustainability and efficiency is expected to drive further innovations, enhancing the role of EPS in global supply chains.

- After-Sales Support and Customer Satisfaction - Providing exceptional after-sales support is crucial for maintaining customer satisfaction and loyalty. Comprehensive support services, such as technical guidance, maintenance plans, and warranty coverage, ensure that clients derive maximum value and performance from their EPS mould purchases.

Image Description

There is no picture description for this product