Supplier of Polystyrene Decorative Moulding Solutions

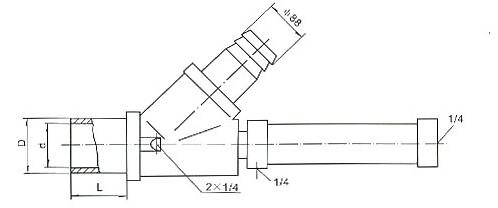

Main Technical Parameters

| Specification | Cylinder Diameter | Remark |

|---|---|---|

| 705 | 3100 | 63 |

| 100 | 8010 | 80 |

Common Product Specifications

| Type | Description |

|---|---|

| Crown Moulding | Classic touch for ceiling-wall junctions |

| Baseboards | Protective finish for wall-floor junctions |

Manufacturing Process

Polystyrene decorative moulding is primarily made from expanded or extruded polystyrene, processes well-documented in materials engineering literature. The EPS process involves expanding beads with steam to form a lightweight foam, while the XPS process involves melting and extruding to create a denser material. These mouldings undergo precision cutting - hot wire cutting or CNC routing, with optional injection moulding for complex designs. Surface coatings of acrylic or polyurethane are applied for additional durability and aesthetic finishes. Studies highlight the material's versatility for diverse applications, suggesting its efficacy as an affordable alternative to wood or plaster due to ease of handling and installation.

Product Application Scenarios

Polystyrene decorative moulding is utilized across residential and commercial environments, from enhancing the interiors of living rooms and bedrooms to highlighting architectural features like columns and eaves in outdoor settings. Scholarly articles confirm its popularity in both modern and traditional designs, attributed to its ability to mimic more costly materials like wood or plaster at a fraction of the cost. The moulding's versatility in design allows architects and homeowners to achieve desired aesthetics without significant investment, offering a practical solution for high-end appearances.

Product After-Sales Service

Our dedicated team ensures comprehensive after-sales support, offering guidance on installation and maintenance. Customers can contact us for any queries regarding product usage and troubleshooting.

Product Transportation

We provide global shipping solutions with secure packaging to ensure the safe arrival of polystyrene moulding products. Our logistics team coordinates with reliable carriers to facilitate timely delivery.

Product Advantages

- Affordability: Cost-effective alternative to traditional moulding materials.

- Durability: Resistant to moisture, rot, and insects.

- Ease of Installation: Lightweight and easy to work with.

- Versatility: Wide range of styles and finishes for customization.

Product FAQ

- What materials are used in Polystyrene Decorative Moulding? Our supplier ensures the use of high-quality expanded or extruded polystyrene, known for its lightweight and durable properties.

- How is the moulding installed? Installation is straightforward, often requiring basic tools and adhesives, nails, or screws. Detailed guidance is available from our supplier support team.

- Can these mouldings be painted? Yes, polystyrene mouldings can be painted with water-based paints to match any decor, enhancing their appearance and longevity.

- What styles of moulding are available? From traditional crown mouldings to modern baseboards, our supplier offers a variety of styles to fit diverse architectural needs.

- Are these mouldings suitable for outdoor use? Yes, our polystyrene mouldings are treated with protective coatings, making them suitable for exterior applications.

Product Hot Topics

- Cost-effective Decorative Solutions: Polystyrene Decorative Moulding is increasingly popular among architects and designers, who value its affordability and versatility. As a leading supplier, we provide high-quality products that cater to diverse aesthetic requirements.

- Innovation in Architecture: The use of Polystyrene Decorative Moulding represents a significant shift in architectural design, offering a practical and stylish alternative to traditional materials. Our supplier expertise ensures top-notch quality and customer satisfaction.

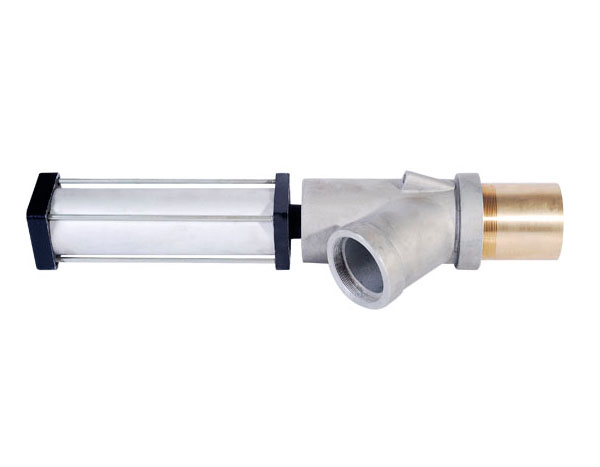

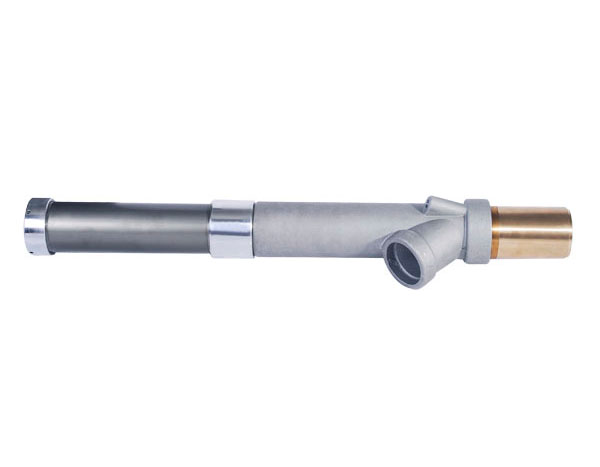

Image Description