Supplier of Advanced EPS Coating Machine Solutions

Product Main Parameters

| Parameter | FAV1200 | FAV1400 | FAV1600 | FAV1750 |

|---|---|---|---|---|

| Mould Dimension (mm) | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 |

| Max Product Dimension (mm) | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 |

| Stroke (mm) | 150~1500 | 150~1500 | 150~1500 | 150~1500 |

| Steam Entry (Inch) | 3''(DN80) | 4''(DN100) | 4''(DN100) | 4''(DN100) |

| Consumption (Kg/cycle) | 5~7 | 6~9 | 7~11 | 8~12 |

| Pressure (Mpa) | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 |

Common Product Specifications

| Feature | Specification |

|---|---|

| Machine Structure | 16~25mm steel plate, strong, no client foundation required. |

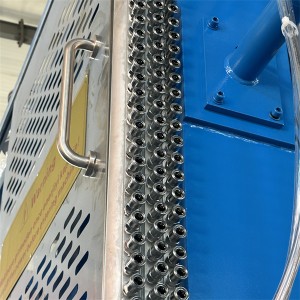

| Filling System | Three modes: normal, vacuum, pressurized. 44 discharging holes. |

| Steam System | Balance valve, Germany electric gauge switch. |

| Cooling System | Vertical vacuum with water spray. |

| Drainage System | Big butterfly valve, fast draining. |

Product Manufacturing Process

EPS Coating Machines involve a meticulous process that begins with surface preparation, ensuring the EPS is clean and primed for optimal adhesion of coatings. The application phase utilizes advanced spray or roller mechanisms for even coverage, vital for both protective and aesthetic coatings. Curing follows, a crucial step where the coating hardens, enhancing the EPS's durability and resistance to environmental factors. Finally, finishing processes might be applied, such as sanding or texturing, to achieve the desired surface appearance. This complex process guarantees high-quality outcomes, as evidenced by numerous authoritative studies in manufacturing technology and material sciences.

Product Application Scenarios

EPS Coating Machines are pivotal across various industries. In construction, they are used for creating insulated panels and building facades, where durability and aesthetics are paramount. In packaging, coated EPS offers superior protection for electronics and fragile items. The versatility extends to decorative applications, including sculptures and signage, where visual appeal and longevity are essential. Authoritative research highlights how these machines facilitate the tailored application of coatings, transforming EPS into a robust material suitable for diverse uses, thus driving innovation in numerous sectors.

Product After-Sales Service

- Comprehensive training for operators on machine use and maintenance.

- 24/7 technical support and troubleshooting assistance.

- Warranty on all components, ensuring peace of mind for our clients.

- Regular updates on software and system improvements.

- On-site service for maintenance and repairs if required.

Product Transportation

Shipping of our EPS Coating Machines is conducted with the utmost care, utilizing sturdy packaging and trusted logistics partners. We ensure timely and safe delivery, understanding the importance of reliable transportation in maintaining the integrity and functionality of our machinery upon arrival. Our logistics team coordinates closely with clients to manage customs documentation and delivery timelines efficiently.

Product Advantages

- Automated operations reduce labor costs and increase efficiency.

- Consistent and high-quality coating output across mass production.

- Flexibility in coating applications, catering to various industries.

- Enhanced durability and aesthetic appeal of finished products.

- Proven technology supported by extensive research and development.

Product FAQ

- What is the primary use of the EPS Coating Machine?

Our EPS Coating Machine is primarily used for applying protective and decorative coatings to EPS products, enhancing their durability, fire resistance, and aesthetic appeal. As a leading supplier, we ensure top-tier technology that meets diverse industry needs.

- How does the machine improve the structural integrity of EPS products?

The coatings applied by our EPS Coating Machine cure into a hard shell, which adds to the structural integrity of EPS products, allowing them to better withstand impacts and loads. This enhancement is a key feature of our offerings as a supplier.

- What industries benefit from EPS Coating Machines?

EPS Coating Machines serve various sectors, including construction, packaging, and decorative arts. Our role as a trusted supplier ensures these industries receive machines optimized for their specific applications.

- Are there different types of coatings available with the machine?

Yes, our EPS Coating Machine can apply various types of coatings, such as cement-based, acrylic, and polyurethane. Each type serves different purposes, from enhancing fire resistance to providing aesthetic finishes. As your supplier, we guide you in choosing the right coating for your needs.

- What are the machine’s power requirements?

Our machines have varying power requirements depending on the model. For example, the FAV1200 model operates at 9 kW. We provide detailed specifications to ensure your facility can accommodate these needs, further supporting you as a reliable supplier.

- How does the machine ensure consistency in coating application?

Our EPS Coating Machine uses advanced automation and control systems to ensure uniform application and consistency across all products, maintaining high-quality standards that we, as suppliers, commit to.

- Is training provided with the purchase of the machine?

Yes, comprehensive training is included with every machine purchase. Our experts offer guidance on operation and maintenance to ensure efficient use, supporting our commitment as a dedicated supplier.

- What maintenance services are available post-purchase?

We provide extensive after-sales support, including regular maintenance, technical assistance, and updates, reinforcing our position as a dependable supplier for your EPS coating needs.

- Are customized solutions available?

Absolutely. We offer customization options to meet specific production requirements, demonstrating our versatility and dedication as a leading supplier of EPS Coating Machines.

- What measures are taken to ensure machine safety?

Safety is a top priority. Our machines include multiple safety features, such as emergency stops and protective casings, ensuring safe operation and reaffirming our role as a responsible supplier.

Product Hot Topics

- Innovations in EPS Coating Machine Technology: Insights from a Leading Supplier

As a leading supplier in the industry, we continuously integrate cutting-edge technologies into our EPS Coating Machines. Recent advancements focus on automation and precision, allowing for superior coating applications that are both efficient and high-quality. Our development team works closely with industry experts to ensure our machines meet evolving market needs, offering clients enhanced capabilities and performance. These innovations not only improve the manufacturing process but also contribute to the broader industry by setting new standards in EPS coating solutions.

- The Environmental Impact of EPS Coating Machines: A Supplier's Perspective

Environmental sustainability is increasingly vital in manufacturing, and as a responsible supplier, we prioritize eco-friendly practices in our EPS Coating Machines. We focus on reducing waste and energy consumption through optimized machine designs and energy-efficient technologies. Our machines support water-based and other environmentally friendly coatings, helping clients achieve their sustainability goals. This commitment to green practices reflects our dedication to responsible manufacturing, ensuring a reduced carbon footprint and minimal environmental impact across our operations.

- Choosing the Right Supplier for EPS Coating Machines: Key Considerations

Selecting the right supplier is crucial for businesses seeking EPS Coating Machines. Key factors include technological expertise, after-sales support, and customization options. As an experienced supplier, we offer comprehensive service packages, ensuring clients receive not only top-quality machines but also the ongoing support necessary for successful operation. Our ability to tailor solutions to specific industry requirements sets us apart, providing added value and ensuring alignment with clients' production goals.

- The Future of EPS in Construction: Advanced Applications of Coating Machines

EPS materials are playing an increasingly significant role in construction, driven by the capabilities of modern coating machines. As a supplier, we provide machines that enhance the thermal, acoustic, and aesthetic properties of EPS panels, making them ideal for sustainable building solutions. The future of EPS in construction is bright, with continued innovations in coating technology expanding its applications. Our machines are at the forefront of this evolution, supporting clients' efforts to incorporate advanced materials in their projects.

- Understanding EPS Coating Standards: Insights from a Supplier's Experience

Industry standards for EPS coating are crucial for ensuring quality and compliance. As a knowledgeable supplier, we help clients navigate these standards, providing machines that meet or exceed industry benchmarks. Our expertise in regulatory requirements and best practices ensures that our clients' products adhere to necessary safety and performance criteria. This understanding is critical for clients seeking to maintain high standards in their manufacturing processes while minimizing risk during product development.

- Maximizing ROI with EPS Coating Machines: Strategies from a Leading Supplier

Investing in EPS Coating Machines can yield significant returns if properly managed. As a supplier, we advise clients on strategies to maximize efficiency and reduce production costs, leveraging cutting-edge technology for optimal performance. Our machines are designed to support high-volume production while minimizing waste and downtime. By implementing best practices in machine operation and maintenance, clients can achieve a substantial ROI, benefiting from enhanced productivity and reduced operational expenses.

- Exploring Customization in EPS Coating Solutions: A Supplier's Approach

Customization is a cornerstone of modern manufacturing, and as a supplier, we emphasize tailored EPS Coating Machine solutions to meet diverse industry needs. Whether adjusting machine specifications for specific product dimensions or incorporating unique coating materials, our customization options enable clients to optimize their production processes. Our approach ensures that each machine is aligned with clients' strategic goals, offering flexibility and adaptability in a rapidly changing market.

- The Role of Automation in EPS Coating Machines: Supplier Insights

Automation is transforming the landscape of EPS coating, offering numerous benefits such as increased efficiency, consistency, and reduced labor costs. As a supplier, we integrate advanced automation technologies into our machines, enhancing precision and reducing human error. This transition allows manufacturers to scale production while maintaining high-quality standards, addressing the growing demand for EPS products across various industries. Automation is not just a trend but a fundamental shift in manufacturing, and our machines are designed to support this evolution.

- Comparing EPS Coating Machine Models: Expert Tips from a Supplier

Choosing the right EPS Coating Machine model can be daunting, given the variety of options available. As an experienced supplier, we guide clients through the selection process, comparing models based on capacity, features, and specific industry applications. Understanding the nuances of each model ensures that clients select equipment that best fits their operational needs and production goals. Our detailed comparison analyses provide valuable insights, helping clients make informed decisions that enhance their manufacturing capabilities.

- The Global Market for EPS Coating Machines: Supplier's Analysis

The global market for EPS Coating Machines is expanding rapidly, driven by increased demand in construction, packaging, and other industries. As a seasoned supplier, we observe trends such as the growing emphasis on energy efficiency, sustainability, and advanced features that enhance productivity and product quality. Our machines are designed to align with these market dynamics, helping clients capitalize on emerging opportunities. Understanding the global market landscape allows us to offer strategic advice and cutting-edge solutions that meet contemporary industry challenges.

Image Description

There is no picture description for this product