Superior Quality EPS Beads Production Line for Fish Box Creation

The product description

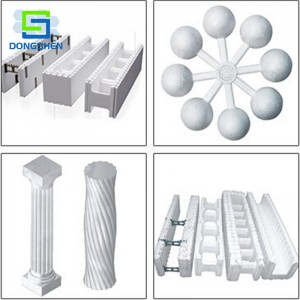

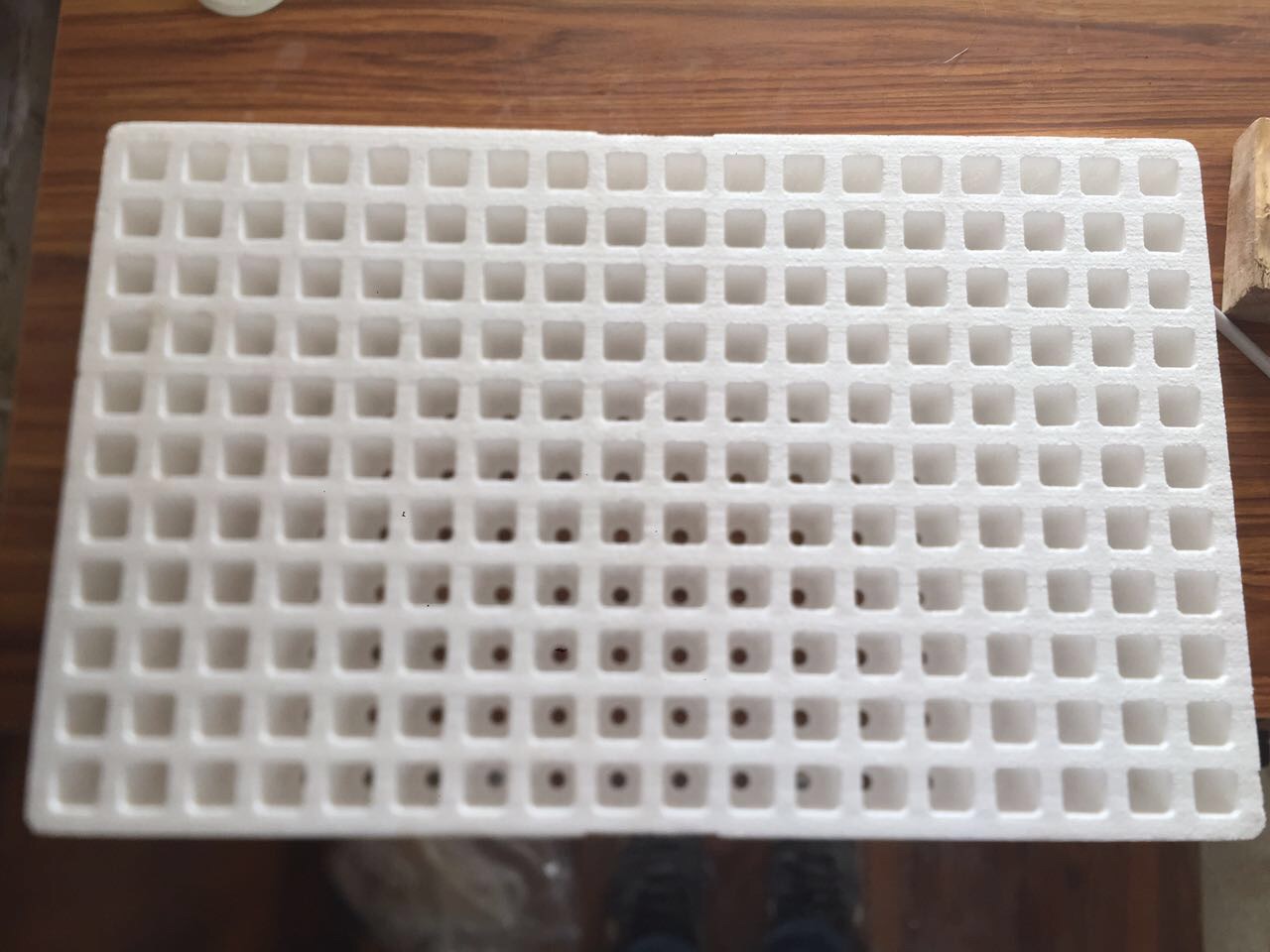

EPS Fish Box Making Machine is used together with mould to produce packaging products like electrical packing, vegetable and fruit boxes, seedling trays etc. and construction products like brick insert and ICF block etc. With different moulds, the machine can produce different shape.

Machine completes with PLC, touch screen, material hopper, efficient vacuum system, lifting legs

Main Features

1. Machine structure: All frames are welded by 16~25mm steel plate, very strong. Machine legs are made by high-strength H type steel profile, foundation is not required from clients.

2. Filling system: Machine allows three filling modes: normal pressure filling, vacuum filling and pressurized filling. Material hopper has sensor to control material level, material discharging is done with rotary discharging plates, total 44 discharging holes.

3. Steam system: adopt balance valve and Germany electric gauge switch to control steaming.

4. Cooling system: vertical vacuum system with water spray device at the top make vacuum efficient.

5. Drainage system: increase mould outlet and use 6 inch drainage pipe and big butterfly valve, make moud draining faster.

Technical Parameter

| Item | Unit | FAV1200 | FAV1400 | FAV1600 | FAV1750 | |

| Mould Dimension | mm | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | |

| Max Product Dimension | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 | |

| Stroke | mm | 150~1500 | 150~1500 | 150~1500 | 150~1500 | |

| Steam | Entry | Inch | 3’’(DN80) | 4’’(DN100) | 4’’(DN100) | 4’’(DN100) |

| Consumption | Kg/cycle | 5~7 | 6~9 | 7~11 | 8~12 | |

| Pressure | Mpa | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | |

| Cooling Water | Entry | Inch | 2.5’’(DN65) | 3’’(DN80) | 3’’(DN80) | 3’’(DN80) |

| Consumption | Kg/cycle | 45~130 | 50~150 | 55~170 | 55~180 | |

| Pressure | Mpa | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 | |

| Compressed Air | Entry | Inch | 1.5’’(DN40) | 2’’(DN50) | 2’’(DN50) | 2’’(DN50) |

| Consumption | m³/cycle | 1.5 | 1.8 | 1.9 | 2 | |

| Pressure | Mpa | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | |

| Capacity15kg/m³ | s | 60~120 | 70~140 | 70~150 | 80~150 | |

| Connect Load/Power | Kw | 9 | 12.5 | 16.5 | 16.5 | |

| Overall Dimension(L*W*H) | mm | 4700*2000*4660 | 4700*2250*4660 | 4800*2530*4690 | 5080*2880*4790 | |

| Weight | Kg | 5000 | 5500 | 6000 | 6500 | |

Case

Related video

This machine by DongShen is a testament to our commitment to quality and innovation. Its versatility and resilience are designed to cater to diverse industrial needs, offering unparalleled performance and consistency. From packaging electronic devices to making boxes for fruits, vegetables, and seedlings, our Eps Beads Production Line is equipped to handle it all - this is the epitome of multifunctionality. In conclusion, our Eps Beads Production Line is a must-have for companies seeking a reliable, cost-effective, and efficient solution for their packaging needs. Backed by DongShen's expertise and dedication to excellence, you can count on us for innovative, robust, and superior quality machinery that will propel your business to greater heights. Experience the best of EPS fish box production with DongShen’s Eps Beads Production Line. Be a part of the future, today!