Revolutionize Fabrication with EPS Batch Preexpander Foam Carving Machine

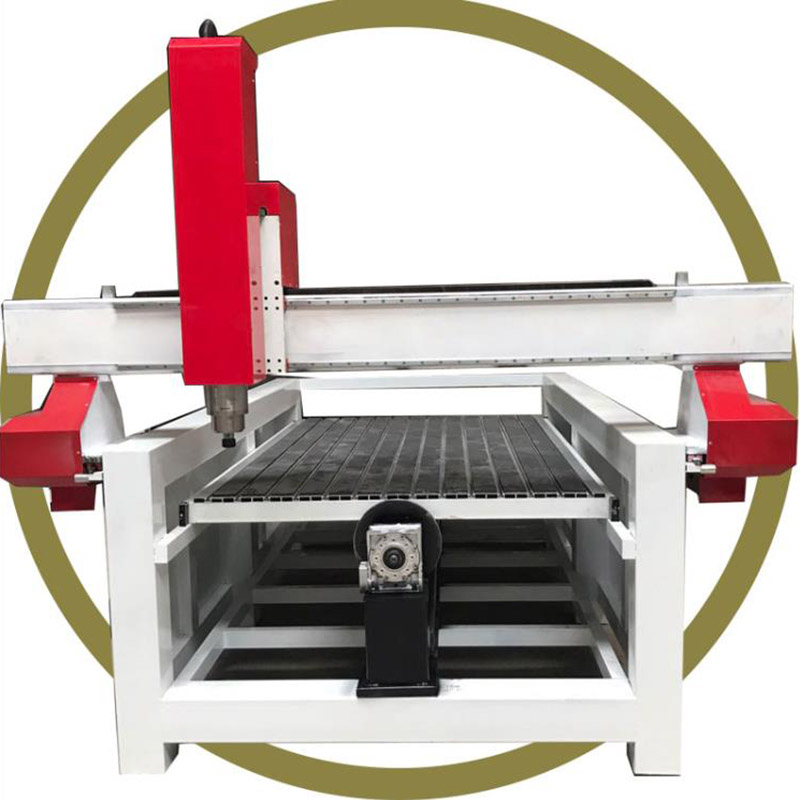

Machine Introduction

EPS CNC router can be used to deal with wood, styrofoam foam and all kinds of non-metallic materials. carving all kinds of large non-metal molds, especially for automobile foam molds, ship models, aviation molds, train molds, food molds (such as moon cake mold) and other precision molds.

Machine Feature

1, Imported four row of steel balls, widened Linear Guide Rail, self-lubricating block. When carving, each direction bears the force equally, guaranteed, the mechanical accuracy and the strength.

2, Z axis stroke size can be 1m, wide processing size, suitable for greater & thicker materails.

3, The intelligent limit protection function prevents damage to the work surface that may be caused by misoperation or software errors. Intelligent processing cross-border protection prevents mechanical collisions caused by the design layout exceeding the processing width.

4, Mutlti-function controlling, fot processing speed, travelling speed and cutting speed. Improving much more quality and efficiency.Diversified control can separately control the processing speed, idling speed, and knife drop speed, which greatly improves the quality and processing efficiency of processed products

5, It has functions such as continuous engraving after power failure, power recovery, processing time prediction, etc., truly humanized design.

Machine appcation

Mold industry: carving all kinds of mold, lost foam mold, automobile foam mold, large wooden block, aviation wooden ship, propeller, train etc.

Musical instrument industry: large-scale musical instrument three-dimensional surface, shape cutting processing;

Applicable materials: styrofoam(EPS), wood substitute, wood and non-metallic carbonized mixture material

Main Technical Parameters

| Model | 1325 EPS foam carving machine | 1830 EPS foam carving machine | 2040 EPS foam carving machine |

| Work Itinerary | 1300*2500mm | 1800*2500mm | 2000*4000mm |

| Feed Height | 500-2000mm | ||

| Max running Speed | 30m/min | ||

| Reposition precision | ±0.05mm | ||

| Cutter Handle Diameter | ¢3、¢4 、¢6 、¢12.7 | ||

| Driving Mode | High Precision Ball Screw | ||

| Spindle Power | 3.5kw/4.5kw/5.5kw/6kw/7.5kw(Optional)0-2400rpm | ||

| Other Powers | 600W | ||

| Working Voltage | 220v50HZ | ||

| Clamping Method | Vacuum adsorption | ||

| Mesa Material | Aluminum Profile + PVC | ||

| Software | TYPE3/Artcam/Castmate/UG/CAD/CAMetc | ||

| Control system | NC studio/Synted/DSP | ||

Case

Related video

The success of DongShen is rooted in continual innovation with the ultimate aim to facilitate our clientele. Our EPS Batch Preexpander is a testament to this commitment. We've created the perfect blend of efficiency, versatility, and innovation all encapsulated within the EPS Batch Preexpander. With this foam carving machine, businesses can elevate their fabrication processes, pushing the boundaries of what is possible. Harness the power of advanced technology and witness a transformation in your production line with the EPS Batch Preexpander Foam Carving Machine, an excellent investment towards growth, efficiency, and innovation. It's time to transform your operations and embrace the future with DongShen's unique foam carving solution.