Revolutionize EPS Processing with Dongshen's Advanced CNC Foam Cutter

Introduction

EPS continuous pre expander machine is functioned to expand EPS raw material to required density, machine works in continuous way both in taking raw material and discharging expanded material.The machine can do second and third expansion to get low density.

EPS continuous pre expander machine with Screw Conveyor,with power-off protection device. First and second expansion loader, Expansion Chamber, Fluidized bed Drier

EPS continuous pre expander machine is a kind of EPS Machine working with mechanical control. EPS raw material is first filled from screw conveyor to expansion loader. At the bottom of loader is the screw, to move material from loader to expansion chamber. During steaming, agitating shaft is moving constantly to make the material density even and uniform. Raw material move to chamber continuously, and after steaming, material level continuously move up, till the material level comes to same level of discharging opening port, then material will automatically flow out. The higher the discharge opening is, the longer the material stays in the barrel, so the lower the density is; the lower the discharge opening is, the shorter the material stays in the barrel, so the higher the density is. The control of the continuous pre-expanding machine is very simple. Whether the steam pressure is stable or not has a great influence on the density of expanding. Therefore, our continuous pre-expanding machine is equipped with a Japanese pressure reducing valve. In order to make the steam pressure in the machine more stable, we use the screw to feed the material at a uniform speed, and the uniform steam and uniform feed are as uniform as possible.

EPS styrofoam beads expanding machine

| Item | SPY90 | SPY120 | |

| Expansion chamber | Diameter | Φ900mm | Φ1200mm |

| Volume | 1.2m³ | 2.2m³ | |

| Usable volume | 0.8m³ | 1.5m³ | |

| Steam | Entry | DN25 | DN40 |

| Consumption | 100-150kg/h | 150-200kg/h | |

| Pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | |

| Compressed Air | Entry | DN20 | DN20 |

| Pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | |

| Drainage | Entry | DN20 | DN20 |

| Throughput | 15g/1 | 250kg/h | 250kg/h |

| 20g/1 | 300kg/h | 300kg/h | |

| 25g/1 | 350kg/h | 410kg/h | |

| 30g/1 | 400kg/h | 500kg/h | |

| Material conveying line | DN100 | Φ150mm | |

| Power | 10kw | 14.83kw | |

| Density | First expansion | 12-30g/l | 14-30g/l |

| Second expansion | 7-12g/l | 8-13g/l | |

| Overall dimension | L*W*H | 4700*2900*3200(mm) | 4905*4655*3250(mm) |

| Weight | 1600kg | 1800kg | |

| Room height required | 3000mm | 3000mm | |

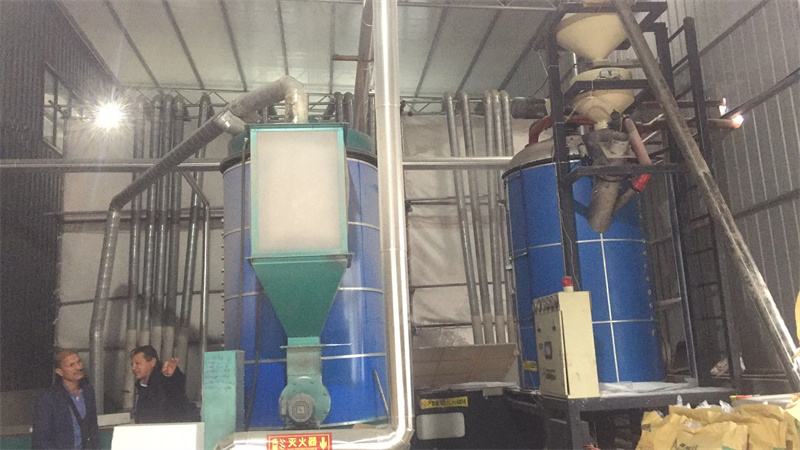

case

Related video

But that's not all. Dongshen's CNC Foam Cutter, an EPS continuous pre-expander machine, also champions efficiency. With its intelligent design, it ensures optimal utilization of resources, reducing waste while maximizing output. This makes it a must-have for any business aiming to optimize production while maintaining the highest quality standards. In the rapidly evolving manufacturing landscape, Dongshen keeps you future-ready. Our CNC Foam Cutter is a testament to our commitment to adopt the latest technology, driving businesses towards success. We understand that every business has unique needs, and our CNC Foam Cutter is designed to meet and exceed these expectations. Invest in Dongshen's CNC Foam Cutter today and step into a future of unlimited potential.