Premium CNC Styrofoam Cutter - Dongshen's Advanced Box Making Solution

Product Details

High quality styrofoam box making machine has efficient vacuum system, fast hydraulic system, and fast drainage system. For the same product, cycle time in E type machine is 25% shorter than in normal machine, and energy consumption is 25% less.

High quality styrofoam box making machine completes with PLC, touch screen, filling system, efficient vacuum system, hydraulic system, electric box

Main Features

Machine plates are made of thicker steel plates so it’s long lasting;

Machine has efficient vertical vacuum system, vacuum tank and condenser tank separate;

Machine use fast hydraulic system, saving mould closing and opening time, using high pressure oil cylinder, hydraulic pressure 140-145bar, hydraulic speed up to 250mm/s.

Different filling methods are available to avoid filling problem in special products, back pressure filling, normal pressure filling, pulse filling, pressurized filing etc choice.

Machine uses big pipe system, allowing low pressure steaming. 3~4bar steam can work the machine;

Machine heating system uses German pressure sensor to control steam pressure.

Components used in the machine are mostly imported and famous branded products, low malfunction;

Machine with lifting legs, so client only need to make a simple working platform for workers.

Machine steam consumption less and working efficiency higher.

Main Technical Parameters

| Item | Unit | FAV1200E | FAV1400E | FAV1600E | FAV1750E | |

| Mould Dimension | mm | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 | |

| Max Product Dimension | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 | |

| Stroke | mm | 150~1500 | 150~1500 | 150~1500 | 150~1500 | |

| Steam | Entry | Inch | 3’’(DN80) | 4’’(DN100) | 4’’(DN100) | 4’’(DN100) |

| Consumption | Kg/cycle | 4~7 | 5~9 | 6~10 | 6~11 | |

| Pressure | Mpa | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | |

| Cooling Water | Entry | Inch | 2.5’’(DN65) | 3’’(DN80) | 3’’(DN80) | 3’’(DN80) |

| Consumption | Kg/cycle | 25~80 | 30~90 | 35~100 | 35~100 | |

| Pressure | Mpa | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 | |

| Compressed Air | Low Pressure Entry | Inch | 2’’(DN50) | 2.5’’(DN65) | 2.5’’(DN65) | 2.5’’(DN65) |

| Low Pressure | Mpa | 0.4 | 0.4 | 0.4 | 0.4 | |

| High Pressure Entry | Inch | 1’’(DN25) | 1’’(DN25) | 1’’(DN25) | 1’’(DN25) | |

| High Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | |

| Consumption | m³/cycle | 1.5 | 1.8 | 1.9 | 2 | |

| Drainage | Inch | 5’’(DN125) | 6’’(DN150) | 6’’(DN150) | 6’’(DN150) | |

| Capacity15kg/m³ | S | 60~110 | 60~120 | 60~120 | 60~120 | |

| Connect Load/Power | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Overall Dimension(L*W*H) | mm | 4700*2000*4660 | 4700*2250*4660 | 4800*2530*4690 | 5080*2880*4790 | |

| Weight | Kg | 5500 | 6000 | 6500 | 7000 | |

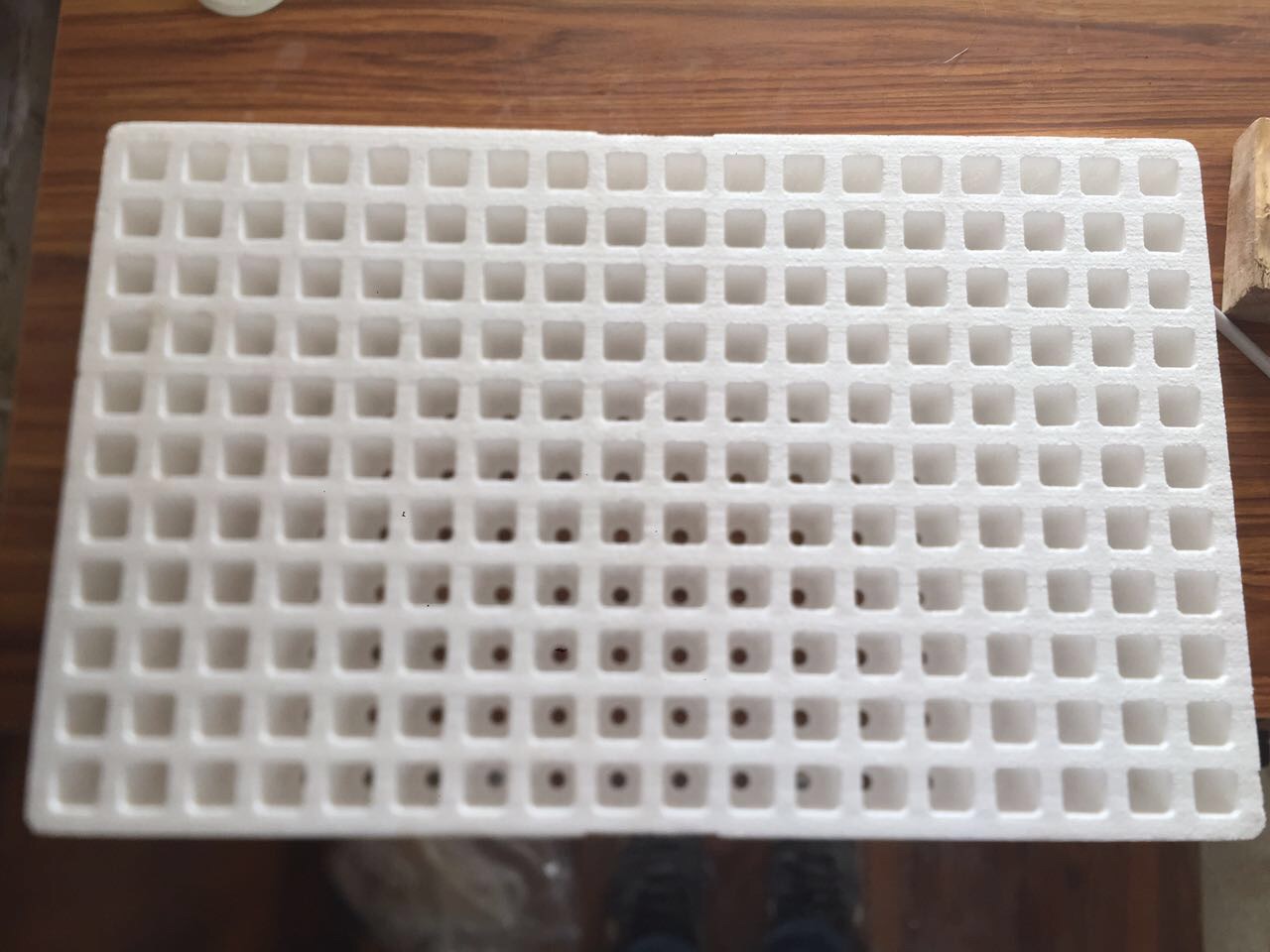

Case

Related video

Every component of our CNC Styrofoam Cutter is made to ensure longevity. Its rapid hydraulic system allows for a smooth and reliable operation, while the efficient vacuum system ensures clean and precise cuts every time. Moreover, the machine's quick drainage capabilities make it ideal for businesses looking to reduce downtime and increase productivity. Choosing Dongshen's CNC Styrofoam Cutter is an investment in quality, speed, and efficiency. Our dedicated team is always ready to provide technical support to ensure that your machine runs without a hitch, prolonging its lifespan and providing excellent value for money. Transform your packaging process with the superior capabilities of our CNC Styrofoam Cutter, and give your business the competitive edge it needs.