Premier Eps Ejector Supplier: DongShen's High-Performance Polystyrene Foam Machine

Product Details

Expanded polystyrene block foam machine is an efficient EPS machine to make EPS blocks. EPS blocks can be cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc.

Expanded polystyrene block foam machine can produce high density EPS blocks, working in fast cycle, and all blocks are straight and strong and with low water moisture. The machine can also make low density blocks with good quality. It can make high density at 40g/l and low density at 4g/l.

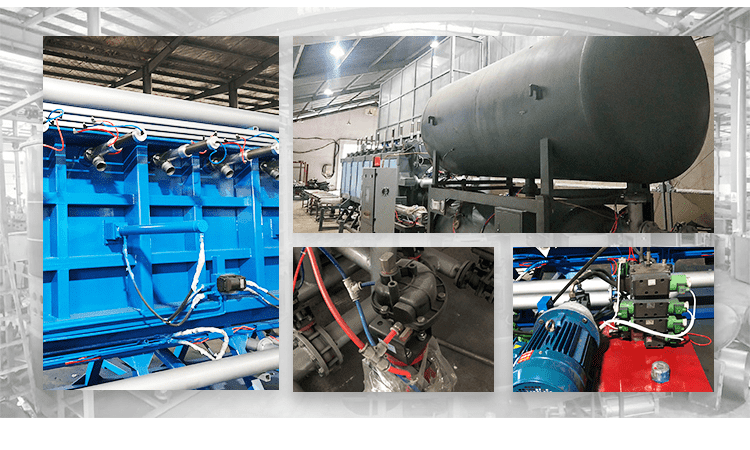

Expanded polystyrene block foam machine complete with main machine body, control box, vacuum system, weighing system etc.

EPS insulation sheets makig machine advantages:

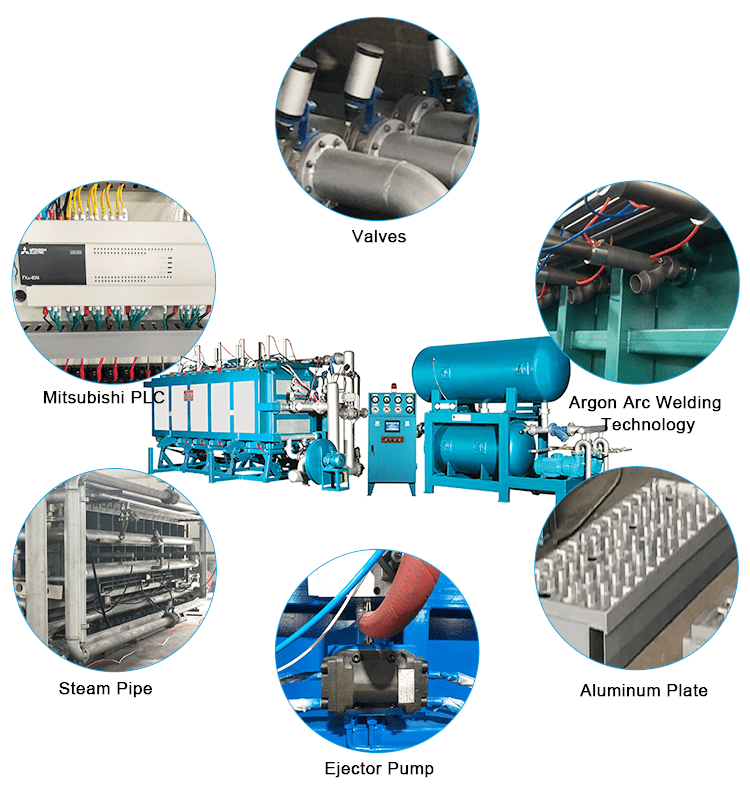

1.Machine is made of high-strength square tubes and thick steel plates;

2.Machine uses 5mm thick aluminum steam plates with Teflon coating. And under aluminum plate, bigger sized supports at more quantity are placed to avoid aluminum plate deform under high pressure. Aluminum plates doesn’t change form after ten years working;

3.Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

4.Machine with more steam lines to ensure steaming even in blocks, so block fusion is better;

5.Machine plates are with better drainage system so blocks are more dried and can be cut in short time;

6.All machine plates through rust removing, ball spraying, then do anti-rust base painting and surface painting, so machine body is not easy to get rusted;

7.Machine use smart piping system and steaming process, ensuring good fusion of blocks both for high density and low density;

8.Fast filling system and efficient vacuum system ensures machine fast working, each block 4~8 minutes;

9.Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

10.Most components used in the machine are imported or famous branded products.

Main Technical Parameters

|

Item |

Unit |

PB2000V |

PB3000V |

PB4000V |

PB6000V |

|

|

Mould Cavity Size |

mm |

2040*1240*1030 |

3060*1240*1030 |

4080*1240*1030 |

6100*1240*1030 |

|

|

Block Size |

mm |

2000*1200*1000 |

3000*1200*1000 |

4000*1200*1000 |

6000*1200*1000 |

|

|

Steam |

Entry |

Inch |

2’’(DN50) |

2’’(DN50) |

6’’(DN150) |

6’’(DN150) |

|

Consumption |

Kg/cycle |

25~45 |

45~65 |

60~85 |

95~120 |

|

|

Pressure |

Mpa |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

|

|

Compressed Air |

Entry |

Inch |

1.5’’(DN40) |

1.5’’(DN40) |

2’’(DN50) |

2’’(DN50) |

|

Consumption |

m³/cycle |

1.5~2 |

1.5~2.5 |

1.8~2.5 |

2~3 |

|

|

Pressure |

Mpa |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

|

|

Vacuum Cooling Water |

Entry |

Inch |

1.5’’(DN40) |

1.5’’(DN40) |

1.5’’(DN40) |

1.5’’(DN40) |

|

Consumption |

m³/cycle |

0.4 |

0.6 |

0.8 |

1 |

|

|

Pressure |

Mpa |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

|

|

Drainage |

Vacuum Drain |

Inch |

4’’(DN100) |

5’’(DN125) |

5’’(DN125) |

6’’(DN150) |

|

Down Steam Vent |

Inch |

4’’(DN100) |

5’’(DN125) |

6’’(DN150) |

6’’(DN150) |

|

|

Air Cooling Vent |

Inch |

4’’(DN100) |

4’’(DN100) |

6’’(DN150) |

6’’(DN150) |

|

|

Capacity 15kg/m³ |

Min/cycle |

4 |

5 |

7 |

8 |

|

|

Connect Load/Power |

Kw |

19.75 |

23.75 |

24.5 |

32.25 |

|

|

Overall Dimension (L*H*W) |

mm |

5700*4000*2800 |

7200*4500*3000 |

11000*4500*3000 |

12600*4500*3100 |

|

|

Weight |

Kg |

5000 |

6500 |

10000 |

14000 |

|

Case

Related video

- Previous:EPS insulation sheets making machine

- Next:Full automatic EPS expanded polystyrene styrofoam block sheet making machine

At DongShen, client satisfaction is our top priority. We understand that every business's need varies, which is why our machine is designed to cater to diverse requirements. Choose us, your reliable Eps Ejector Supplier, to experience the transformation that our Expanded Polystyrene Block Foam Machine can bring to your EPS production process. With our machine at your disposal, you take a step towards a future of higher quality, greater productivity, and assured success.