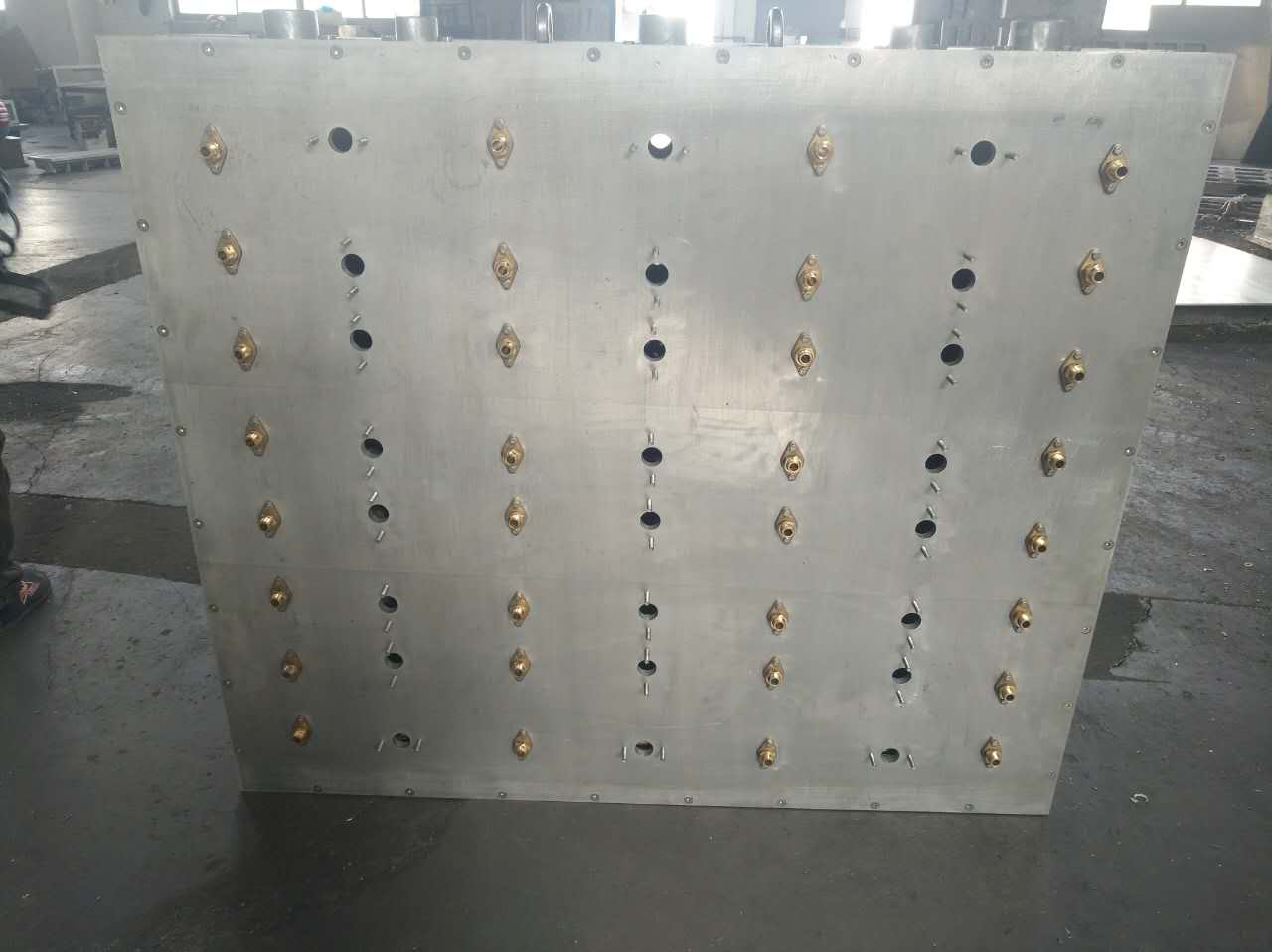

Manufacturer of High-Quality Styrofoam Form Fish Box Moulds

| Main Technical Parameters | Specifications |

|---|---|

| Steam chamber | 1200*1000mm, 1400*1200mm, 1600*1350mm, 1750*1450mm |

| Mould size | 1120*920mm, 1320*1120mm, 1520*1270mm, 1670*1370mm |

| Patterning | Wood or PU by CNC |

| Machining | Fully CNC |

| Alu alloy plate thickness | 15mm |

| Packing | Plywood box |

| Delivery | 25~40 days |

Common Product Specifications

| Material | Specification |

|---|---|

| Aluminum Ingot | High-quality, 15mm~20mm thick aluminum alloy plates |

| CNC Processing | Fully CNC with tolerance within 1mm |

| Coating | Teflon coating for easy demoulding |

Product Manufacturing Process

Our EPS fish box moulds are manufactured following a meticulous process to ensure high quality and durability. Initially, high-grade aluminum ingots are sourced and formed into thick plates. These plates undergo CNC machining to achieve precise dimensions with a tolerance within 1mm. Post-machining, the moulds are assembled and coated with Teflon to facilitate easy demoulding. Each step, from patterning and casting to assembling and coating, is subject to strict quality control measures.

According to authoritative papers, EPS mould manufacturing is a detailed and technical process involving several stages of quality checks to ensure the end product meets the desired standards. The use of CNC machines guarantees precision, while Teflon coating ensures smooth operation and longevity of the moulds.

Product Application Scenarios

EPS fish box moulds are primarily used in packaging applications where insulation and lightweight properties are crucial. These moulds are ideal for creating fish boxes that help maintain the temperature and safety of perishable goods during transport. Authoritative studies have shown that EPS packaging is highly effective for temperature-sensitive products, reducing spoilage and extending shelf life.

Additionally, EPS fish boxes crafted using these moulds are widely used in the seafood industry due to their superior insulation properties and shock absorption capabilities. This ensures that the products remain fresh and intact throughout the supply chain.

Product After-Sales Service

We offer comprehensive after-sales service for our EPS fish box moulds, including technical support, maintenance, and repair services. Our experienced engineers are available to assist with any issues and provide guidance on optimizing mould performance.

Product Transportation

Our products are securely packed in plywood boxes to prevent any damage during transportation. We ensure timely delivery, typically within 25 to 40 days from the date of order confirmation.

Product Advantages

- High-quality aluminum material ensures durability and longevity.

- Precision CNC machining guarantees accurate mould sizes.

- Teflon coating facilitates easy demoulding and enhances productivity.

- Experienced engineers provide custom designs for complex mould requirements.

Product FAQ

- Q: What materials are used in your EPS fish box moulds? A: Our moulds are made from high-quality aluminum ingots, ensuring durability and robustness.

- Q: What is the lead time for delivery? A: Generally, our delivery time ranges from 25 to 40 days depending on order specifications.

- Q: Do you offer custom designs? A: Yes, we provide custom design services tailored to your specific needs and requirements.

- Q: How do you ensure the quality of your moulds? A: We implement strict quality control processes at every step, from patterning to Teflon coating.

- Q: What are the common applications of EPS fish box moulds? A: They are primarily used for packaging perishable goods, providing excellent insulation and shock absorption.

- Q: Do you provide after-sales support? A: Yes, we offer comprehensive after-sales support including technical assistance and maintenance services.

- Q: What is the thickness of the aluminum plates used? A: We use aluminum alloy plates with a thickness ranging from 15mm to 20mm.

- Q: Are your moulds compatible with machines from other countries? A: Yes, our moulds are designed to be compatible with EPS machines from countries like Germany, Korea, Japan, and Jordan.

- Q: How are the moulds packed for transportation? A: The moulds are securely packed in plywood boxes to prevent any damage during transport.

- Q: Can you convert customer samples to CAD or 3D drawings? A: Yes, we offer conversion services from customer samples to CAD or 3D drawings for precise manufacturing.

Product Hot Topics

- Comment: The quality of EPS fish box moulds from Dongshen is unmatched. As a manufacturer, they have consistently provided us with durable and precise moulds that meet our exact specifications. The CNC machining ensures that every mould is produced with the highest accuracy, which is crucial for our packaging needs. Additionally, their after-sales support is excellent, always ready to assist with any issues. We highly recommend their products to anyone in need of reliable EPS moulds.

- Comment: Our company has been sourcing EPS fish box moulds from Dongshen for over a decade. Their commitment to quality and precision is evident in every product we have received. The Teflon coating on the moulds makes the demoulding process effortless, significantly improving our productivity. Dongshen's ability to create custom designs tailored to our needs has been incredibly beneficial. Their thorough quality control measures ensure that every mould we receive is of the highest standard.

- Comment: Dongshen's expertise in manufacturing EPS fish box moulds is unparalleled. The high-quality aluminum alloy plates and precise CNC machining result in moulds that are both durable and accurate. Their ability to convert our samples into detailed CAD drawings has streamlined our production process. With a lead time of 25 to 40 days, they have always met our deadlines. The secure packaging in plywood boxes ensures that the moulds arrive in perfect condition.

- Comment: As a manufacturer in the seafood industry, the insulation and shock absorption properties of EPS fish boxes are crucial for us. Dongshen's EPS fish box moulds have consistently provided us with high-quality packaging solutions. Their technical support team is highly knowledgeable and always available to assist with any concerns. The compatibility of their moulds with our existing EPS machines has made the integration seamless.

- Comment: We have been using Dongshen's EPS fish box moulds for several years, and the quality has been exceptional. The CNC machining ensures precise dimensions, and the Teflon coating makes the demoulding process smooth. Dongshen's engineers are highly experienced and have designed complex moulds for us that meet our unique requirements. Their commitment to quality and customer satisfaction sets them apart from other manufacturers.

- Comment: Dongshen's EPS fish box moulds have significantly improved our packaging capabilities. The high-quality aluminum material and precise CNC machining result in moulds that are durable and reliable. The Teflon coating ensures easy demoulding, which has increased our production efficiency. Dongshen's ability to create custom designs tailored to our needs has been invaluable. Their after-sales support is prompt and effective.

- Comment: The EPS fish box moulds from Dongshen are of superior quality. The CNC machining guarantees precise sizes, and the Teflon coating facilitates easy demoulding. The aluminium alloy plates used are thick and durable. Their engineers have extensive knowledge and experience, which is evident in the quality of the moulds. The secure packaging and timely delivery further enhance their service. We are highly satisfied with their products.

- Comment: Dongshen has been our go-to manufacturer for EPS fish box moulds for years. Their commitment to quality and precision is commendable. The high-quality aluminum plates and Teflon coating ensure durability and easy demoulding. The CNC machining results in accurate mould sizes. Their after-sales support is excellent, always ready to assist with any issues. We highly recommend Dongshen's EPS fish box moulds to anyone in need of reliable packaging solutions.

- Comment: Our experience with Dongshen's EPS fish box moulds has been outstanding. The high-quality aluminum material and precise CNC machining result in durable and accurate moulds. The Teflon coating makes the demoulding process smooth, enhancing our production efficiency. Dongshen's ability to create custom designs tailored to our needs has been incredibly beneficial. Their after-sales support is prompt and effective, ensuring our complete satisfaction.

- Comment: Dongshen's EPS fish box moulds have exceeded our expectations. The quality of the aluminum alloy plates and the precision of the CNC machining are remarkable. The Teflon coating ensures easy demoulding, significantly improving our productivity. Dongshen's engineers are highly experienced and have designed complex moulds for us that meet our unique requirements. The secure packaging and timely delivery further enhance their exceptional service. We highly recommend their products to anyone in need of high-quality EPS moulds.

Image Description

There is no picture description for this product