Manufacturer of EPP Injection Molding Filling Gun

Product Main Parameters

| Type | Specification | Remark |

|---|---|---|

| Common Type | 221480; 100; 120; 150; 180; 200; 220 | Length 150 and 180 are the common models. |

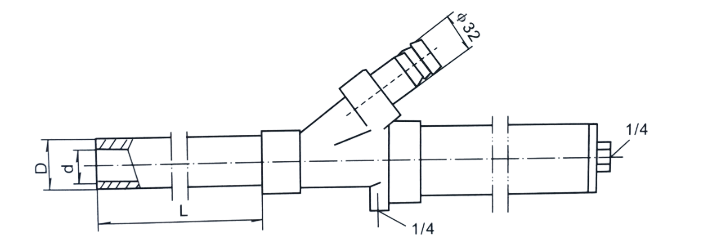

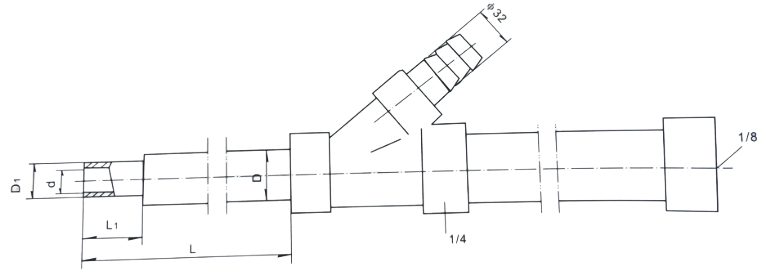

| Air Front Small Head | 30; 150; 180; 1410 | Feeding air pipe interface 1/4 |

| German Type | 50; 310; 2016; 2535 | Stainless steel barrel, specify if copper needed |

Common Product Specifications

| Part | Specification |

|---|---|

| Feeding Air Pipe Interface | 1/4 |

| Cylinder Diameter | Range 22–50 |

Product Manufacturing Process

EPP injection molding is a specialized manufacturing process that involves molding expanded polypropylene beads under controlled conditions. This process begins with the pre-expansion of EPP beads using steam to expand them to the desired density. These beads are then injected into a custom-designed mold where they are subjected to further heat, causing them to expand and fuse, filling the mold cavity completely. The process concludes with cooling, during which the part solidifies, and is then ejected from the mold. According to a study published in the Journal of Materials Processing Technology, this method is recognized for producing parts with high impact resistance and thermal insulation properties, making it particularly useful for applications in the automotive and packaging industries.

Product Application Scenarios

In the automotive industry, EPP injection molding is utilized to produce components such as bumper cores and energy absorbers due to the material's lightweight and impact-resistant properties. EPP's excellent thermal insulation capabilities make it ideal for packaging solutions, protecting delicate electronics during shipping. Additionally, consumer goods such as sports helmets and children’s toys benefit from EPP's durability and recyclability. A comprehensive review in the International Journal of Advanced Manufacturing Technology emphasizes EPP's role in sustainable manufacturing due to its recyclability and energy efficiency in production processes.

Product After-Sales Service

We offer a comprehensive after-sales service package that includes technical support, replacement parts, and a maintenance guide to ensure optimal performance and longevity of your EPP Injection Molding Filling Gun.

Product Transportation

Products are shipped using secure, climate-controlled logistics services to maintain product quality and integrity during transit. We ensure timely delivery and tracking for all orders.

Product Advantages

- Lightweight and impact resistant

- Thermal insulation properties

- Recyclable and environmentally friendly

- Customizable mold designs

Product FAQ

- What materials are used in EPP injection molding? EPP injection molding uses expanded polypropylene beads, known for their lightweight and durable properties.

- How does the EPP injection molding process work? The process involves pre-expanding EPP beads, filling them into molds, and using heat to expand and fuse them into finished parts.

- Is EPP environmentally friendly? Yes, EPP is 100% recyclable and aligns with sustainable manufacturing practices.

- What industries benefit from EPP products? Industries such as automotive, packaging, and consumer goods commonly use EPP products for their lightweight and energy-efficient properties.

- Can EPP products be customized? Yes, we offer custom mold designs to fit specific requirements.

- How do I maintain the EPP Filling Gun? Regular cleaning and inspection are recommended to ensure ongoing performance.

- What is the expected lifespan of an EPP Filling Gun? With proper maintenance, EPP Filling Guns are designed for long-term use.

- Do you offer technical support? Yes, we provide comprehensive technical support and troubleshooting services.

- How are the products shipped? Products are carefully packaged and transported using secure logistics services.

- What if I encounter a problem with my order? Contact our customer service team for prompt assistance and resolution.

Product Hot Topics

- Why Choose EPP Injection Molding? EPP Injection Molding offers numerous advantages, including reduced weight, excellent shock absorption, and recyclability, making it an excellent choice for manufacturers seeking sustainable solutions.

- Innovations in Automotive with EPP The automotive industry increasingly adopts EPP Injection Molding for parts that benefit from weight reduction, leading to improved fuel efficiency and safety enhancements in vehicle design.

- Packaging Solutions with EPP EPP is revolutionizing the packaging sector by providing superior protection for delicate goods, contributing to reduced shipping damage and enhanced product safety.

- Sustainability in Manufacturing The environmental benefits of EPP, such as its recyclability and energy-efficient production process, are driving its adoption in eco-conscious manufacturing sectors.

- Advancements in EPP Molding Technology Continuous improvements in EPP molding technology are expanding its applications across industries, providing versatility in product design and functionality.

- Challenges in EPP Mold Design Designing EPP molds can be complex, but the rewards include highly customizable and efficient products tailored to specific industry needs.

- Economic Benefits of EPP The cost savings associated with lightweight EPP products, recyclable materials, and energy efficiency offer significant economic benefits to manufacturers.

- Future Trends in EPP Usage As industries increasingly seek sustainable solutions, EPP is poised for growth due to its environmental benefits and adaptability.

- Comparing EPP with Traditional Materials EPP provides distinct advantages over traditional polymers, especially in terms of weight, durability, and environmental impact.

- Customer Feedback on EPP Products Customers consistently report high satisfaction with EPP products, praising their durability, versatility, and environmental benefits.

Image Description