Manufacturer of Advanced 4 Axis CNC Foam Cutter

Product Main Parameters

| Axes of Movement | 4 (X, Y, Z, A or C) |

|---|---|

| Cutting Tool | Hot wire, saw, or router bit |

| Material | EPS, XPS, polyurethane |

Common Product Specifications

| Width | 1200mm |

|---|---|

| Length | 2000mm—6000mm or customized |

| Wire Diameter | Φ2.5mm-Φ3.0mm |

| Capacity | 50-55 steps/min; 150m²/h |

Product Manufacturing Process

4 Axis CNC Foam Cutters undergo a meticulous design and manufacturing process to ensure precise control and optimal performance. The engineering starts with digital models created using CAD software, which are then programmed into the CNC system via G-code. This automation allows the machine to execute precise, repeatable cuts across multiple axes. The foam material is secured in place, and the cutting tool—often a hot wire or router bit—is guided along the programmed path to achieve the desired shape. This process is supported by a robust control system that manages the axes movements with high precision, ensuring the production of complex geometries and exact dimensions. Efficiency is enhanced by integrating reliable components and sensors for self-testing and automatic alarms, minimizing downtime and maintenance requirements. As the technology evolves, manufacturers continually refine these processes to push the boundaries of what is achievable with foam cutting, making it an invaluable tool across various industries.

Product Application Scenarios

The 4 Axis CNC Foam Cutter is widely utilized in industries like aerospace, automotive, architecture, and art. In aerospace, the cutter produces lightweight, structurally integral components that meet stringent safety and performance criteria. In the automotive industry, it facilitates rapid prototyping and precise mold creation for diverse vehicle parts. Architects and artists leverage the cutter's precision to create intricate models and sculptures, translating digital designs into tangible works with exceptional accuracy. The machine's versatility in handling various foam types makes it suitable for producing custom packaging inserts, enhancing product protection during transit. By streamlining the foam cutting process, manufacturers of the 4 Axis CNC Foam Cutter enable industries to achieve greater innovation and efficiency, aligning with the evolving demands of their fields.

Product After-Sales Service

Our dedicated after-sales support ensures customer satisfaction through comprehensive technical assistance, machine maintenance, and parts replacement. We offer remote troubleshooting and on-site service options, backed by a team of skilled technicians. Regular maintenance packages help prolong machine life and optimize performance. Customer training sessions are available to enhance operational expertise and maximize equipment utilization. Additionally, our user-friendly online portal provides resources, manuals, and FAQs for self-service solutions. By prioritizing customer needs, we reinforce our commitment as a trusted manufacturer of the 4 Axis CNC Foam Cutter, fostering long-term relationships built on quality and reliability.

Product Transportation

We manage the safe and efficient transportation of our 4 Axis CNC Foam Cutters using specialized packaging methods to prevent damage during transit. Our logistics partners are chosen for their expertise in handling machinery, ensuring timely deliveries globally. Customers can select from flexible shipping options, including sea, air, or land transport, tailored to meet specific requirements. Comprehensive insurance coverage is available to provide additional peace of mind. Tracking services are offered, allowing customers to monitor their shipments from dispatch to delivery, reinforcing our commitment as a leading manufacturer of the 4 Axis CNC Foam Cutter.

Product Advantages

- Precision and Accuracy: Achieves highly precise and repeatable cuts, crucial for industries requiring exact specifications.

- Complex Cuts: Capable of creating intricate designs and complex shapes that are challenging manually.

- Efficiency: Automates the cutting process, reducing time and labor costs compared to manual cutting.

- Versatility: Can handle different types of foam, making it suitable for diverse industries.

Product FAQ

- What is a 4 Axis CNC Foam Cutter? A specialized machine using computer numerical control for precision foam cutting across four axes, enhancing versatility and precision.

- What materials can it cut? The cutter is ideal for EPS, XPS, and polyurethane foams, providing accuracy and efficiency across these materials.

- What industries benefit from this machine? Aerospace, automotive, architecture, and packaging industries find extensive applications for our 4 Axis CNC Foam Cutter.

- What are the key features of this cutter? Its four-axis capability, precision cutting tools, and robust software integration make it highly efficient and versatile.

- How is the machine operated? Operators use CAD/CAM software to design and translate patterns into G-code, which guides the cutting processes.

- What are the advantages over traditional cutters? Offers more complex, accurate cuts and reduced manual labor, saving time and increasing productivity.

- What maintenance is required? Regular maintenance, parts inspection, and software updates ensure optimal performance and longevity.

- Is training available for operators? Yes, we provide detailed training sessions and resources to enhance operator skills and machine handling.

- Can the machine be customized? Yes, we offer customization options to meet specific client requirements, enhancing its applicability.

- How can I purchase a machine? Contact our sales team for inquiries, quotes, and further information on purchasing options.

Product Hot Topics

- Innovations in Foam Cutting Technology: Manufacturers are constantly seeking to push the boundaries of foam cutting with advancements like the 4 Axis CNC Foam Cutter, which combines precision engineering and adaptable features to meet the diverse demands of modern industries. The integration of CAD/CAM software allows seamless transition from design to execution, enabling manufacturers to achieve complex geometries and intricate designs with ease. As industries like aerospace and automotive require more precise and efficient manufacturing processes, the role of advanced cutters becomes indispensable.

- Maximizing Efficiency with CNC Foam Cutters: The advent of the 4 Axis CNC Foam Cutter has transformed traditional manufacturing processes by significantly enhancing efficiency and precision. As a leading manufacturer, we focus on delivering machines that automate complex cuts with high reproducibility, thereby reducing labor costs and increasing output. Industries appreciate the cutter's ability to handle versatile foam types while maintaining superior accuracy, crucial for meeting the evolving challenges in sectors such as architecture and packaging.

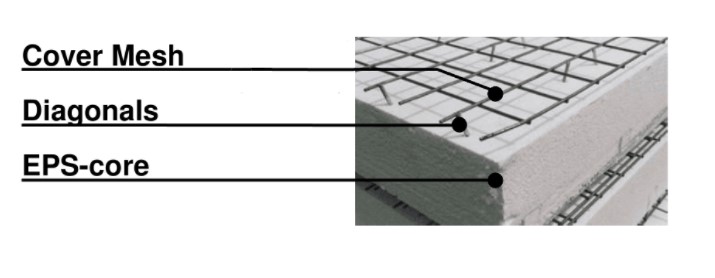

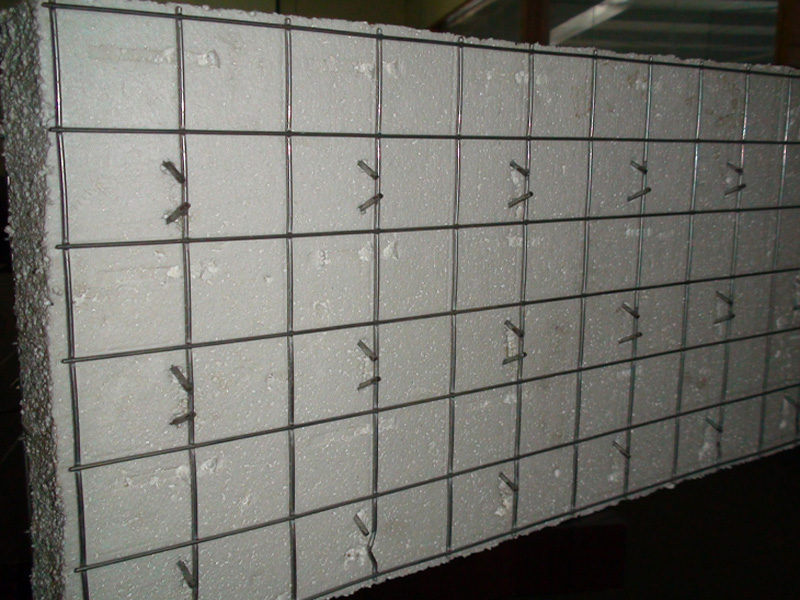

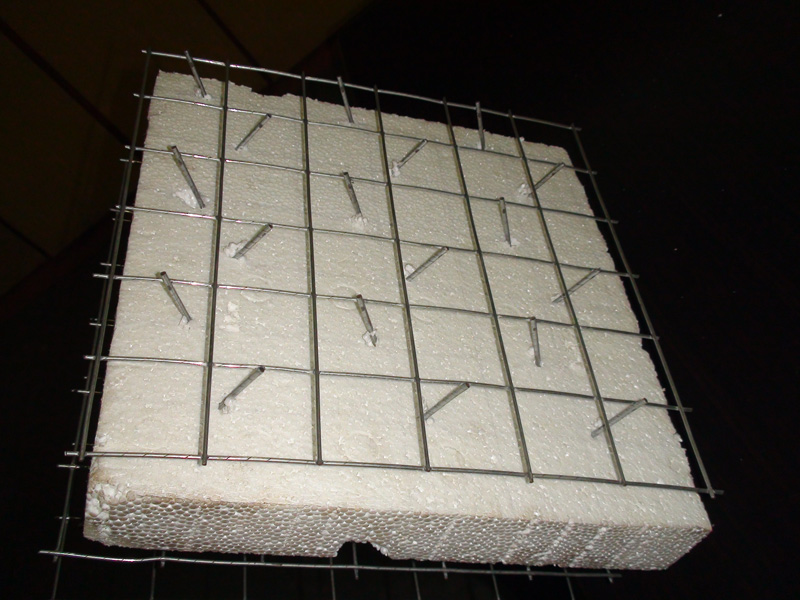

Image Description