Leading Supplier of Advanced EPS Reactors

EPS Reactor Main Parameters

| Parameter | Value |

|---|---|

| Material | Stainless Steel |

| Capacity | Up to 10,000 L |

| Temperature Range | 10°C - 80°C |

| Pressure Range | 0 - 10 bar |

Common Product Specifications

| Specification | Details |

|---|---|

| Power Supply | 380V/50Hz |

| Protection Level | IP65 |

| Control System | PLC Integrated |

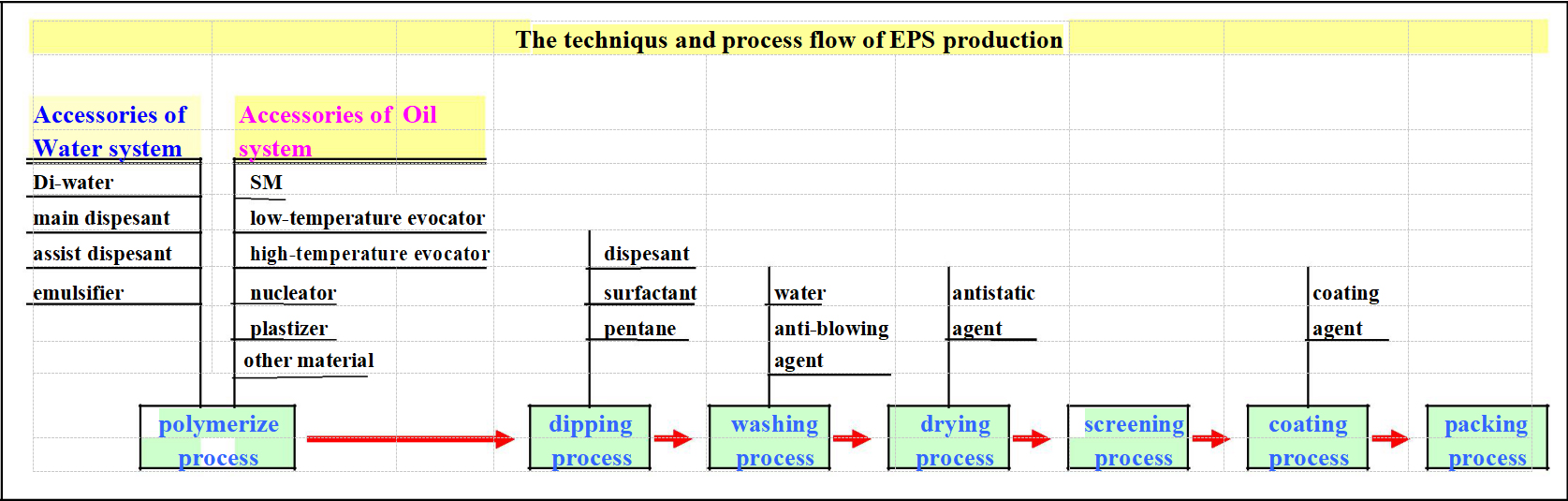

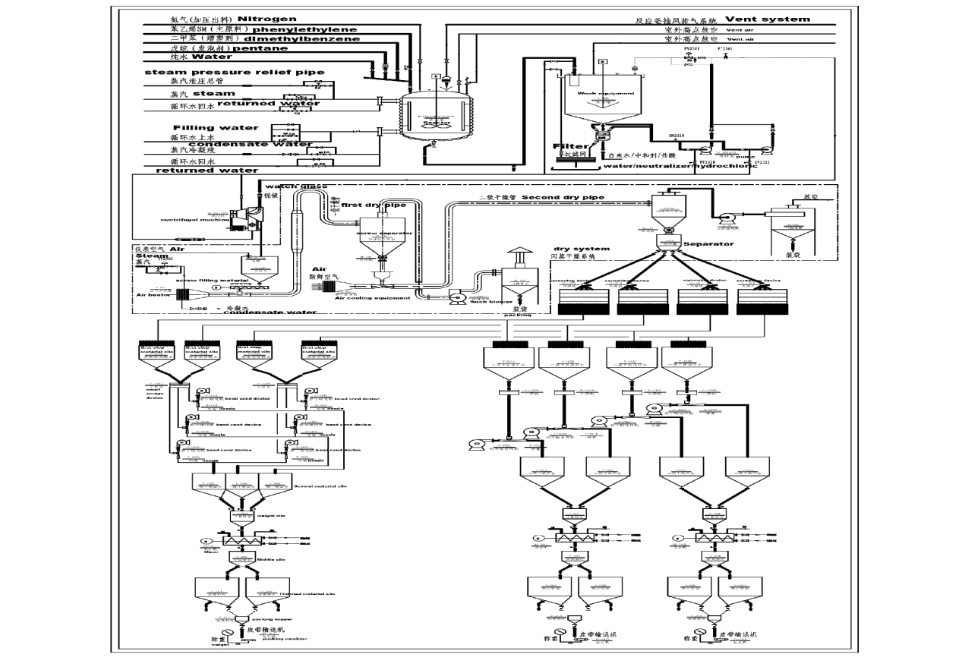

Product Manufacturing Process

The manufacturing process of EPS Reactors involves precise assembling of stainless steel components, followed by rigorous testing to ensure leak-proof and high-performance systems. Drawing from recent studies, the incorporation of advanced welding techniques and corrosion-resistant materials contribute to enhanced reactor longevity. The design prioritizes ease of maintenance and operational efficiency, minimizing downtime and operational costs. The focus on innovative engineering ensures the EPS Reactor meets high environmental and safety standards, making it an indispensable tool in modern wastewater treatment facilities.

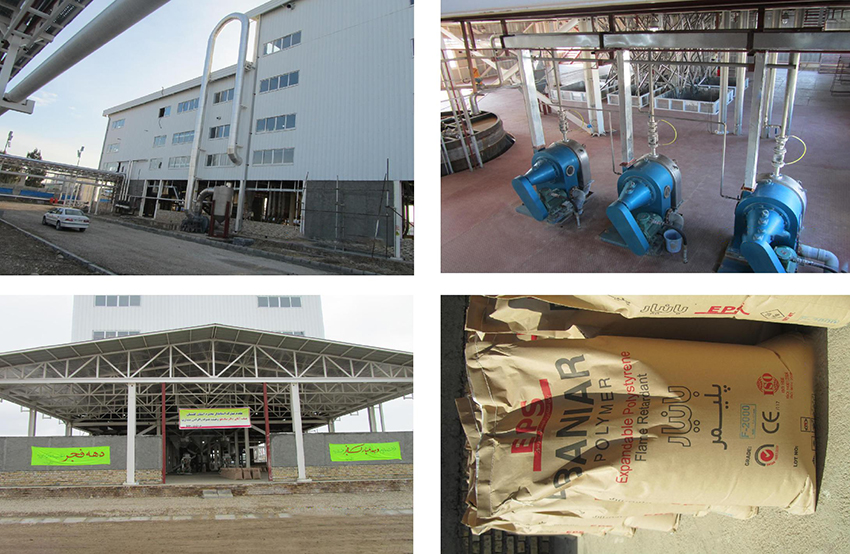

Product Application Scenarios

EPS Reactors play a pivotal role in various wastewater treatment applications, including municipal and industrial wastewater management. According to recent research, these reactors effectively reduce biochemical oxygen demand (BOD) and chemical oxygen demand (COD) levels, ensuring compliance with regulatory standards. Their adaptability to fluctuating environmental conditions makes them suitable for diverse climatic zones and operational scales—from small local plants to large metropolitan facilities. Such versatility and efficiency underline the importance of EPS Reactors in achieving sustainable wastewater management goals worldwide.

Product After-Sales Service

Dongshen provides comprehensive after-sales services, including installation support, maintenance training, and 24/7 technical assistance for all EPS Reactor systems. Regular performance evaluations and updates ensure systems operate at peak efficiency.

Product Transportation

We ensure safe and timely delivery of EPS Reactors via global logistics partners. Each shipment is securely packaged to mitigate damage risks during transit, with tracking available for real-time delivery updates.

Product Advantages

- High operational efficiency with reduced energy consumption

- Robust design for long-term durability

- Flexible application across multiple industries

- State-of-the-art control systems for precise operations

Product FAQ

- What is an EPS Reactor?

An EPS Reactor is a specialized bioreactor used in wastewater treatment, leveraging microbial biofilms to effectively process and reduce pollutants.

- Why choose Dongshen as your EPS Reactor supplier?

Dongshen offers unparalleled expertise, cutting-edge technology, and comprehensive support, making it a trusted supplier of EPS Reactors globally.

- How does the EPS Reactor handle temperature fluctuations?

Our reactors are engineered to maintain optimal functionality across a wide temperature range, ensuring consistent performance even with environmental changes.

- What maintenance is required for EPS Reactors?

Regular inspections and cleaning are recommended to ensure optimal performance. Dongshen provides maintenance guides and support.

- Can EPS Reactors handle high-pressure applications?

Yes, our reactors are built to withstand significant pressure, offering reliable operations for demanding industrial applications.

- Is it possible to customize reactor specifications?

Dongshen provides customization options to cater to specific operational requirements, ensuring the EPS Reactor fits seamlessly into existing setups.

- How do EPS Reactors improve wastewater quality?

By utilizing microbial biofilms, our reactors enhance the breakdown of organic pollutants, resulting in cleaner effluent output.

- What are the safety features of EPS Reactors?

Our reactors include robust safety mechanisms, such as automatic shutdowns and alerts, to prevent operational hazards and ensure user safety.

- How is the EPS Reactor's efficiency measured?

Efficiency is gauged by the reduction in pollutant metrics, like BOD and COD, and consistent reactor operation under specified conditions.

- What technical support does Dongshen offer for EPS Reactors?

We provide 24/7 technical assistance, regular system updates, and on-site support to ensure continuous reactor efficiency and resolve issues promptly.

Product Hot Topics

- The Future of Wastewater Treatment: EPS Reactors

The potential of EPS Reactors is reshaping the wastewater treatment landscape, offering sustainable and efficient solutions. As environmental regulations tighten globally, the demand for advanced treatment technologies is soaring. EPS Reactors, with their ability to handle varying loads and conditions, are at the forefront of this innovation. Industries and municipalities alike are recognizing their value, leading to a surge in adoption and research. This trend is expected to continue, heralding a new era in sustainable water management.

- EPS Reactors: Meeting the Challenges of Urban Waste Management

Urbanization poses significant wastewater management challenges. EPS Reactors provide a robust solution, effectively addressing the complexities of urban waste streams. Their adaptability and efficiency make them ideal for metropolitan environments, where space and resource constraints are prevalent. With growing urban populations, EPS Reactors represent a critical innovation in maintaining urban sanitation standards while minimizing environmental impact.

- Customizing EPS Reactors for Industry-Specific Needs

Industries have distinct wastewater treatment requirements. EPS Reactors' customization capabilities allow for tailored solutions that meet specific industrial needs. Whether dealing with high organic loads or specific chemical pollutants, these reactors can be adjusted to optimize performance. This flexibility ensures that industries can maintain compliance without compromising on operational efficiency, marking EPS Reactors as pivotal for industrial environmental strategies.

- Operational Efficiency Through EPS Reactor Innovations

Continual innovation in EPS Reactor technology is enhancing operational efficiencies. Recent advancements have focused on improving energy consumption, throughput, and system integration. These enhancements translate to lower operational costs and increased treatment capacity, making EPS Reactors not only an environmental choice but an economically sound one as well. As innovations continue, these reactors are positioned to become even more integral to cost-effective wastewater treatment solutions.

- EPS Reactors in Developing Regions: A Game Changer

For developing regions facing water treatment infrastructure limitations, EPS Reactors offer a transformative solution. Their efficiency and low maintenance requirements provide a feasible option for regions with limited resources. Implementing these reactors can significantly improve water quality and public health, showing their potential as a catalyst for change in developing areas. The economic and environmental benefits make EPS Reactors a key player in global water management strategies.

- Environmental Impact of EPS Reactors

EPS Reactors have been shown to reduce environmental impact by lowering pollutant levels in treated water. By efficiently managing contaminants, these reactors help to protect aquatic ecosystems and reduce the strain on natural water bodies. This environmentally-friendly approach to wastewater treatment underscores the importance of EPS Reactors in achieving sustainable development goals, aligning industrial processes with environmental conservation efforts.

- Comparing EPS Reactors to Traditional Wastewater Systems

EPS Reactors offer significant advantages over traditional wastewater systems. Their ability to operate under varying loads and conditions provides greater flexibility and efficiency. Additionally, the reduced sludge production and enhanced treatment capabilities position EPS Reactors as superior alternatives for modern wastewater challenges. Organizations transitioning to these advanced systems report improved performance and compliance with environmental regulations, highlighting the benefits of adopting EPS technology.

- Maximizing Resource Utilization with EPS Reactors

Resource optimization is crucial in wastewater management. EPS Reactors contribute to this by maximizing biofilm efficacy and minimizing waste. Their design allows for efficient nutrient and contaminant processing, reducing the need for additional resources. This efficiency leads to cost savings and a smaller environmental footprint, aligning with broader goals of sustainable resource management and economic efficiency.

- Scaling EPS Reactors for Large-Scale Applications

As wastewater demands increase, the scalability of EPS Reactors becomes a critical asset. These systems can be adjusted to meet large-scale operational needs, making them suitable for extensive municipal or industrial applications. The ability to scale without compromising performance ensures that EPS Reactors remain effective as demand grows, providing a reliable solution for large-scale wastewater treatment challenges.

- Innovative Maintenance Strategies for EPS Reactors

Effective maintenance is key to sustaining EPS Reactor performance. Innovations in predictive maintenance technologies are enabling more efficient upkeep, reducing downtime and prolonging system life. These strategies focus on early detection of potential issues, ensuring that reactors continue to operate at peak efficiency. Adopting advanced maintenance practices reflects a commitment to long-term operational success, reinforcing the reliability of EPS Reactors in demanding environments.

Image Description