Innovative EPS Foaming Machine for High-quality Floor Heating Panel Lamination

Operation process

Manually place the EPS panel at the corresponding position on the tray --- press the start button --- the laminating frame automatically presses down --- the electric furnace oven automatically moves forward --- the heating time is timed --- the tray time delay enters the timing end --- the tray automatically enters the timing end --- the heating time is timed out --- the tray automatically rises to start the blistering molding --- the electric furnace oven moves backward --- the cooling time is timed out --- the laminating frame automatically rises --- the tray automatically drops --- the automatic sheet pulling --- the tray drops into place --- the tray Automatically move out to the initial state - manually insert the second EPS panel

Functional design and features

1. Pulling function: It adopts the form of frequency converter, variable frequency motor, and reducer to pull the plate. The output force is large, and the pulling speed can be adjusted at will. The encoder is used to control the pulling length, resulting in high precision of the pulling length.

2. Heating brick temperature control method:

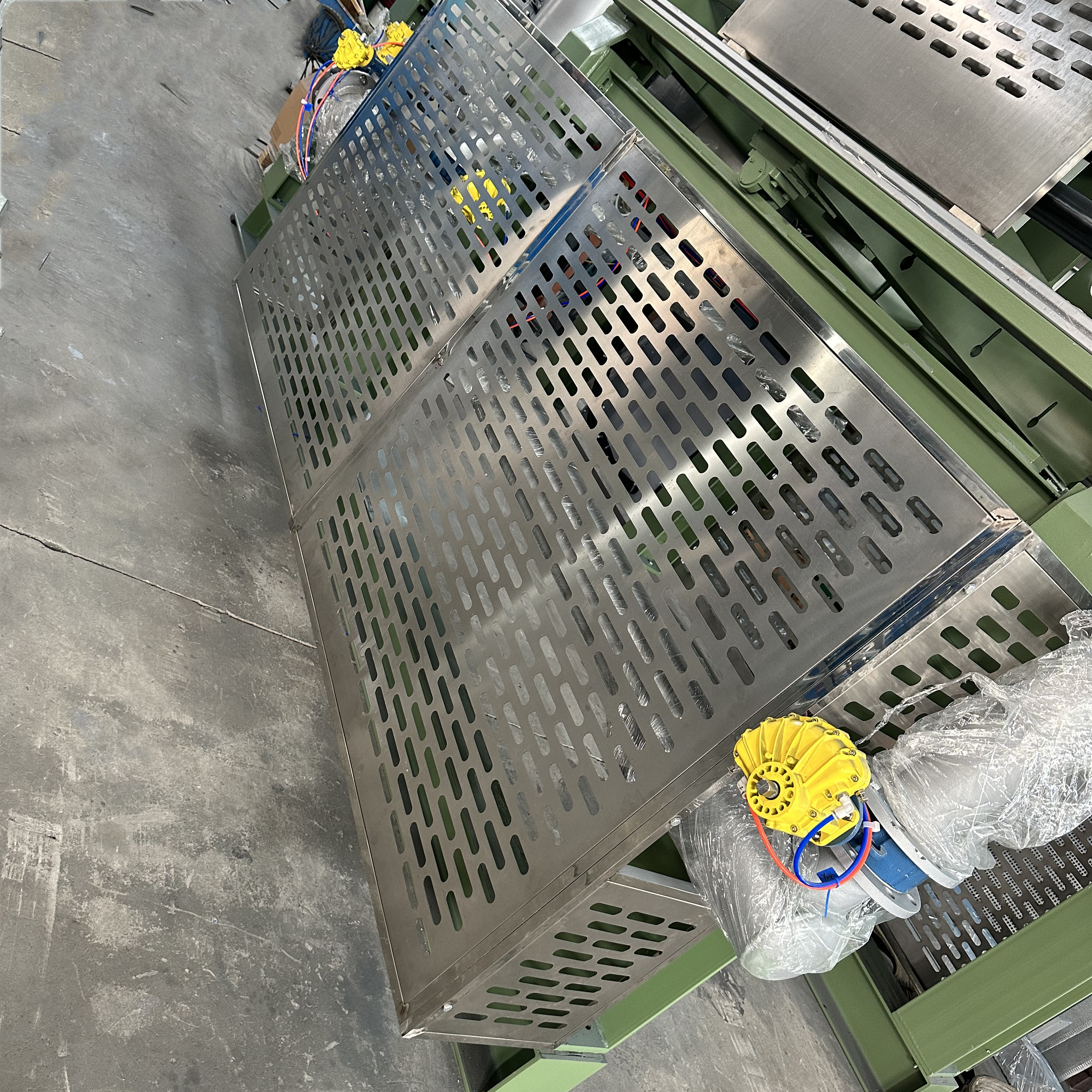

Standard configuration: It adopts a two wire embedded far infrared ceramic heating brick for heating, with a heating brick size of 120cm square. The heating power of each heating brick can be independently controlled to achieve uniform temperature throughout the layout, and any heating brick can be turned off.

3. Automatic flattening function: After the EPS panel is coated with film, due to the cooling shrinkage of the film, the EPS panel protrudes and deforms towards the uncoated side. This machine is equipped with horizontal and vertical automatic flattening mechanisms at the discharge point to flatten the coated EPS panel horizontally and vertically.

4. Oven forward and backward movement function: The electric furnace oven adopts an automatic forward and backward movement mode, which can ensure that the plastic sheets are not affected by the preheating of the oven.

6. The width of the guide rail spacing can be adjusted: according to different sizes of modules, or manually adjust the distance between the two slide rails according to the width of plastic sheets to meet production requirements.

7. Product mold tray forward and backward movement function: The tray for placing the EPS panel to be coated is moved forward and backward. When placing, the tray is moved outside the machine, and the operator can easily place the EPS panel outside. The tray design has a delayed entry function, and the plastic sheet is heated and softened before entering, reducing the deformation caused by long-term heating of the foam board.

8. Replaceable function of the mold plate: the mold plate of different specifications and sizes needs to be replaced when the eps foam plates of different specifications and sizes are coated. The replaceable function of the mold plate realizes the multi-purpose of one machine.

Length | 800~1380mm |

Width | 600~960mm |

Height | 100mm |

Sheet thickness | 0.03~2mm |

Working speed | 2~3 panels per minute according to the different thickness of sheet |

Power | Pneumatic |

Machine overall size | 9200*3300*2100mm |

Weight | 4.8T |

case

Related video

Once the allotted time lapses, the laminating frame ascends automatically while the tray lowers. This heralds the start of the automatic sheet pull and ends with the tray returning to its original position. This comprehensive process smoothly transitions through each phase, ensuring precision and consistency in every output. The second EPS panel can be effortlessly inserted manually, ready to undergo the same thorough procedure. This EPS Foaming Machine isn't just a device, it's a blueprint for streamlined operation and high-quality outputs. It's the embodiment of our commitment to providing innovative, cost-effective, and sustainable solutions for our clients. With Dongshen's EPS Foaming Machine, revolutionize how you approach floor heating panel production.