High-Performance EPS Expansion Machine for Floor Heating Panels by Dongshen

Functional design and features

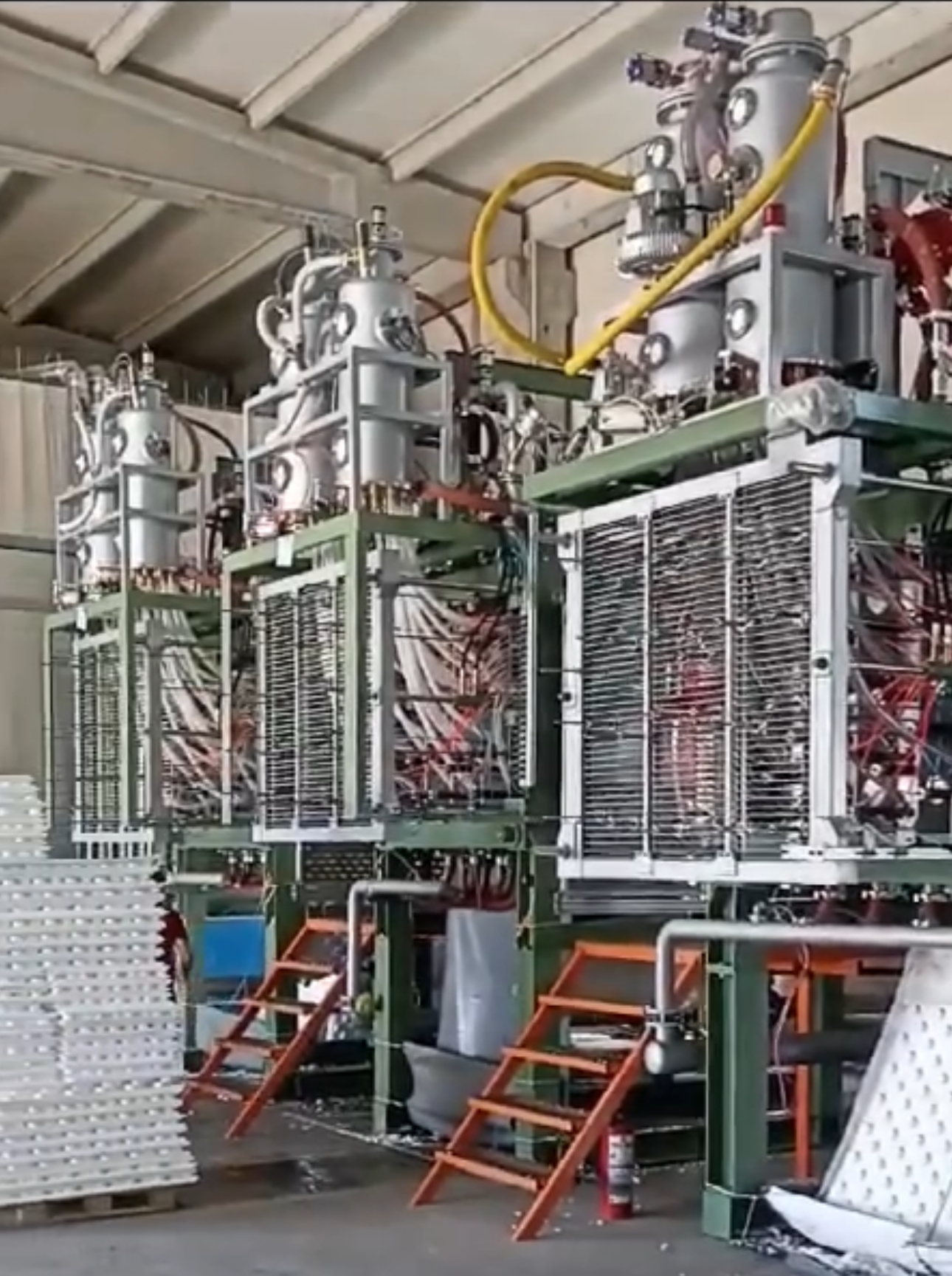

EPS vacuum casting machine for floor heating panel is used together with mould to produce packaging products like electrical packing, vegetable and fruit boxes, seedling trays etc. and construction products like brick insert and ICF etc. With different moulds, the machine can produce different shape.

EPS vacuum casting machine for floor heating panel has efficient vacuum system, fast hydraulic system, and fast drainage system. For the same product, cycle time in E type machine is 25% shorter than in normal machine, and energy consumption is 25% less.

Machine completes with Mitsubishi PLC and Schneider (or Winview) touch screen, with big steam lines for better heating and low pressure heating, material hopper with quick couplers for fast changing filling hoses, with Stainless Steel air quick couplers for fast changing air tubes

Machine features

EPS vacuum casting machine for floor heating panel Main Features

Machine plates are made of thicker steel plates so it’s long lasting;

Machine has efficient vacuum system, vacuum tank and condenser tank separate;

Machine use fast hydraulic system, saving mould closing and opening time;

Different filling methods are available to avoid filling problem in special products;

Machine uses big pipe system, allowing low pressure steaming. 3~4bar steam can work the machine;

Machine steam pressure and penetration steaming are controlled by German Pressure manometer and pressure regulators;

Components used in the machine are mostly imported and famous branded products, low malfunction;

Machine with lifting legs, so client only need to make a simple working platform for workers.

Item | Unit | PSZ-1200E | PSZ-1514E | PSZ-1600E | PSZ-1750E | PSZ-2200E | |

Mould Dimension | mm | 1200*1000 | 1500*1400 | 1600*1350 | 1750*1450 | 2200*1650 | |

Max Product Dimension | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 | 2050*1400*400mm | |

Stroke | mm | 150~1500 | 150~1500 | 150~1500 | 150~1500 | 150~1500 | |

Steam | Entry | Inch | 3’’(DN80) | 4’’(DN100) | 4’’(DN100) | 4’’(DN100) | 5’’(DN125) |

| Consumption | Kg/cycle | 4~7 | 5~9 | 6~10 | 6~11 | 9~11 |

| Pressure | Mpa | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 |

Cooling Water | Entry | Inch | 2.5’’(DN65) | 3’’(DN80) | 3’’(DN80) | 3’’(DN80) | 4’’(DN100) |

| Consumption | Kg/cycle | 25~80 | 30~90 | 35~100 | 35~100 | 35~100 |

| Pressure | Mpa | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 | 0.3~0.5 |

Compressed Air | Low Pressure Entry | Inch | 2’’(DN50) | 2.5’’(DN65) | 2.5’’(DN65) | 2.5’’(DN65) | 2.5’’(DN65) |

| Low Pressure | Mpa | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| High Pressure Entry | Inch | 1’’(DN25) | 1’’(DN25) | 1’’(DN25) | 1’’(DN25) | 1’’(DN25) |

| High Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Consumption | m³/cycle | 1.5 | 1.8 | 1.9 | 2 | 2.5 |

Drainage | Inch | 5’’(DN125) | 6’’(DN150) | 6’’(DN150) | 6’’(DN150) | 8’’(DN200) | |

Capacity15kg/m³ | S | 60~110 | 60~120 | 60~120 | 60~120 | 60~120 | |

Connect Load/Power | Kw | 9 | 12.5 | 14.5 | 16.5 | 17.2 | |

Overall Dimension(L*W*H) | mm | 4700*2000*4660 | 4700*2250*4660 | 4800*2530*4690 | 5080*2880*4790 | 5100*2460*5500 | |

Weight | Kg | 5500 | 6000 | 6500 | 7000 | 8200 | |

case

Related video

Inherent in its DNA, the EPS Expansion Machine's ability to produce floor heating panels is an asset in today's energy-conscious world. Efficient floor heating panels are an integral part of sustainable construction and minimizing energy use, and Dongshen’s EPS Expansion Machine plays an indispensable role in achieving this. In conclusion, our EPS Expansion Machine is not just a tool, but a solution to modern industry challenges. It signifies Dongshen's promise to deliver functional, efficient, and reliable products to its consumers, driving their business growth while ensuring sustainability. Choose Dongshen's 2200E EPS Expansion Machine to experience the revolution in floor heating panel and packaging production.