Ungon Dong Ethenak

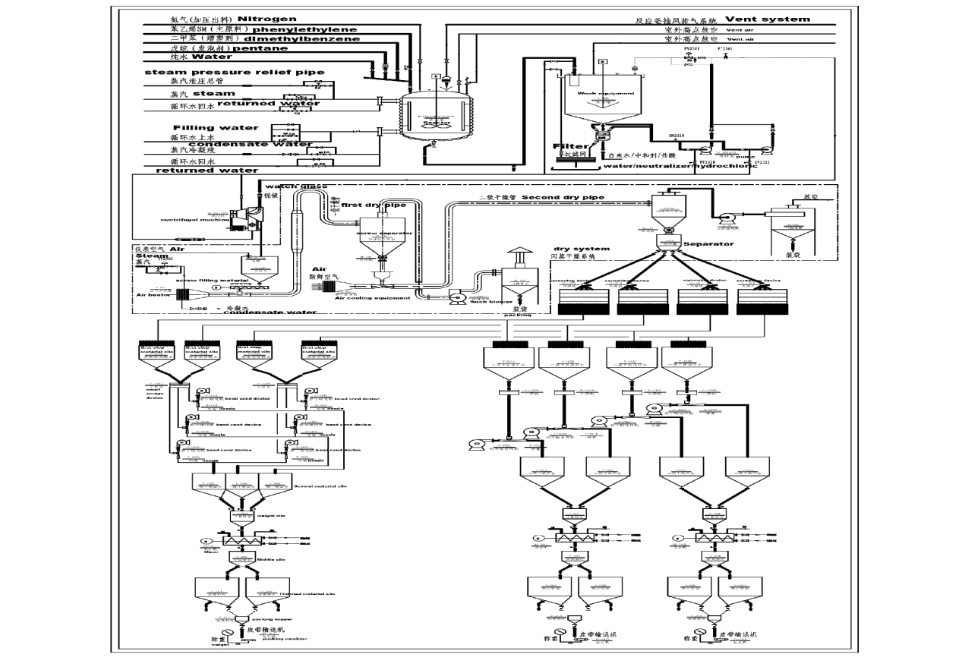

Takaitawa EPS(Fadada Polystyrene) Raw kayan aiki

Aiwatar da abin gabatarwa

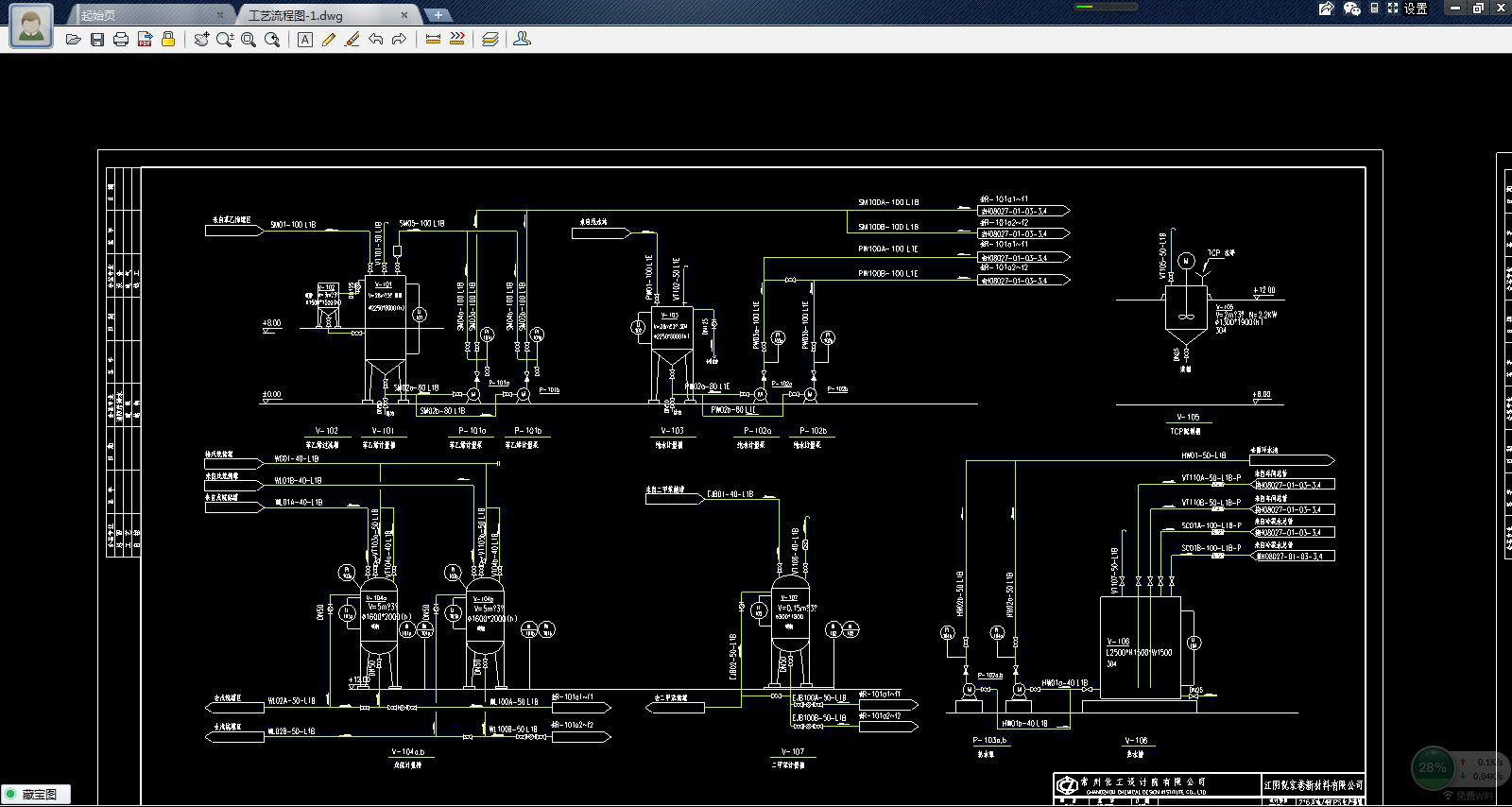

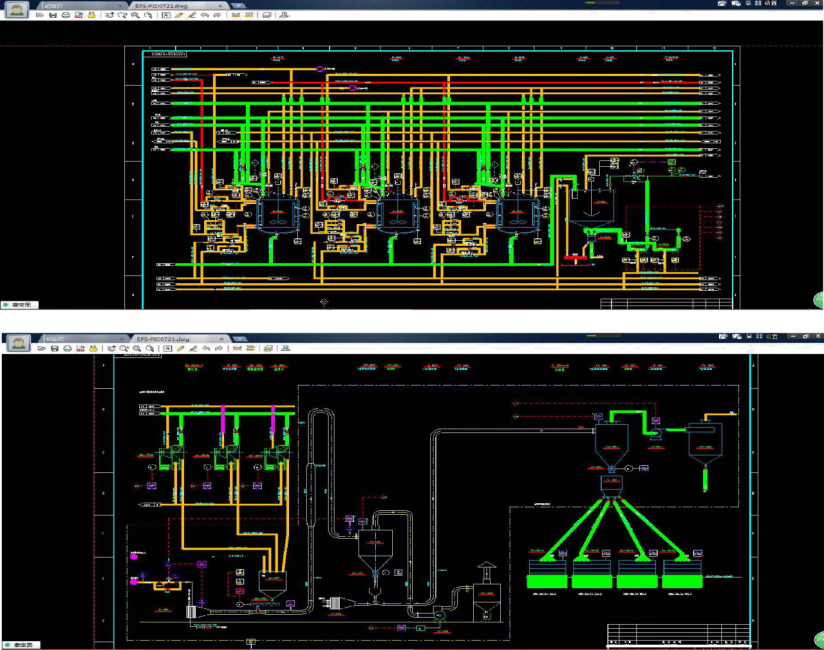

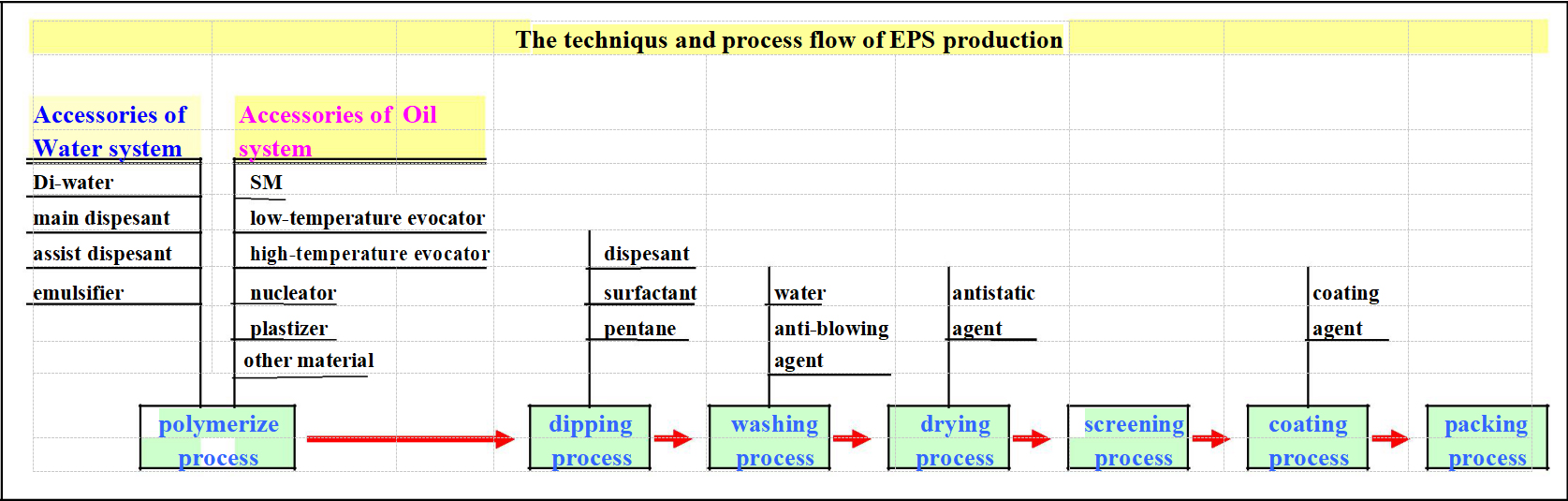

Tsarin daya) wanda ya hada da polemization, rashin daidaituwa, sanyaya, wankewa, siga, jarrabawar jijiyoyi, shirya. Matsakaicin lokacin samarwa na samar da EPS shine 16 ~ 17 hours.

(1) polymerization da impregnation

Polymerization da impregnation an tabbatar a cikin reactor. A karkashin wani hali, sm zai polymerize. Ta hanyar comfenuous mura, SM za a iya tsawaita kuma a yanka a cikin tube, sannan kuma tsara tsarin saukad da sm mai da aka dakatar a cikin ruwa saboda matsin lamba. Akwai wutsiyoyi na dakatar da ruwa don guje wa bankin sm kuma haɗa tare. A cikin wannan tsari ikon da ake magana ya kamata ya fi ƙarfin haɗawa don tabbatar da low - zazzabi polyerization.

Thearancin - Amincewa da ƙwaƙwalwar ciki yana gudana a cikin digo na SM, da ruwan sanyi ya cire shi ta hanyar ruwan sanyi a cikin shirin. Don cire zafi cikin lokaci, dole ne mu tabbatar da aikin al'ada na tsarin samar da ruwa yayin aiwatar da aiki. In ba haka ba, zazzabi a cikin reactor zai yi yawa, wanda ke haifar da amsawa da sauri da kuma danko.

An sarrafa tsarin samar da hannu da hannu, yayin aiwatarwa, yakamata a sarrafa yanayin zafin jiki daidai don guje wa manyan sauƙin, in ba haka ba, za a fadada girman beads girman. A lokacin, akai-akai lura da samfurori yana da mahimmanci don sarrafa girman beads.

Ta hanyar daidaita nauyi mai nauyi caco3 da tcp, girman beads za a iya sarrafa.

Ana amfani da tsarin DCS don sarrafa zafin jiki yayin dukkanin dumama, polymerization, impregnation, high - zazzabi dauki, da sanyaya. Don tabbatar da samar da tsaro, tsarin DCS zai sarrafa hakkin zafi da lokacin, da kuma ƙararrawa ko magana.

Lokacin da aka canza tsarin sm kai kusan 75% (kimanin 4 zuwa 5 a ƙarƙashin zazzabi na yau da kullun), ya kamata a ƙara takamaiman wakili mai hurawa. Bayan imprening da polymerization a kan wani lokaci da matsin lamba, zamu iya samun beads na EPS.

Wakilin hurawa don impregnation ne allurar a cikin aunawa da ke aunawa da famfo, kuma daidai nauyin nauyin da aka yi nauyi. Bayan babban - Tsarin kwastomomi, lokacin sanyaya zuwa zazzabi, kayan za a iya fitar da kayan zuwa wanka na wanki.

(2) Wanke

Rashin daidaituwa kamar watsawa da kuma cire hanyoyin da za'a cire su ta hanyar wanka. Bayan tsaftacewa, za a bushe beads da ruwan tabarau na EPS don cire ruwa mafi yawan ruwa, kuma shirye don cigaba bushewa.

Hakanan zamu iya amfani da DE. Wakilin Foaming don cire ƙazanta.

(3) bushewa

Bayan daskarewa ta centrifugal, za a yi kusan ragowar ruwa a saman beads na EPS (abin da ke cikin ruwa mai bushewa da ake buƙata, yayin wannan tsari, beads suna bushe da iska mai zafi. Hurawa ta iska mai zafi, ruwan ƙasa maza ya zama tururi, to, irin wannan cakuda - zai iya haifar da ƙarancin iska, kuma tura iska mai laushi, kuma tura iska mai laushi mai laushi yana gudana zuwa cibiyar Cibiyar. Ta haka za a bushe beads.

Bayan bushewa iska mai zafi, beads suna buƙatar sanyaya da iska mai sanyi don ci gaba rage rage abun cikin ruwa, kuma shirya don ɗorewa. Don hana tara wutar lantarki, ya kamata a ƙara wakilin etistatic yayin bushewa.

Zaɓuɓɓukan bushewa yana sarrafawa ta tsarin DCS.

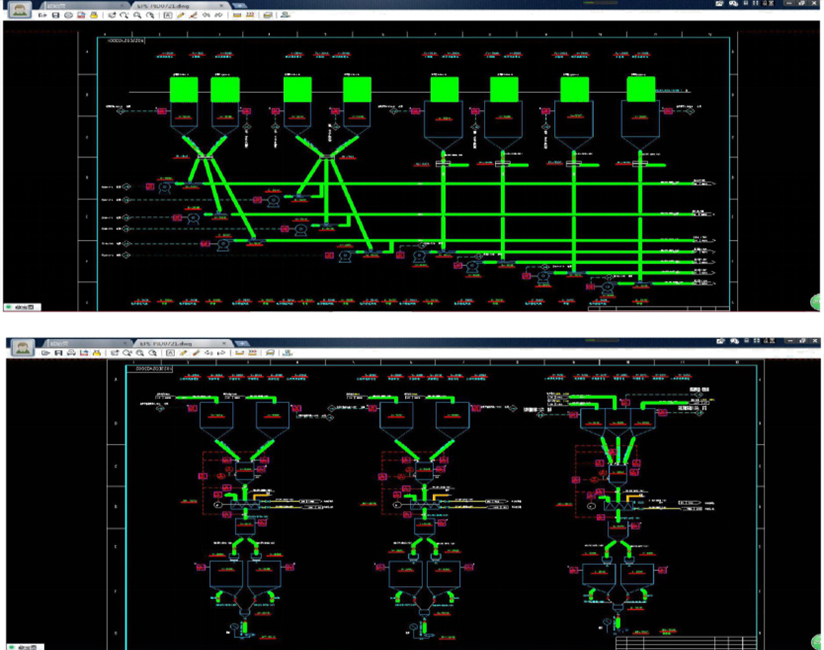

(4)

Girman abubuwan da aka bushe na EPS ɗin da aka bushe, suna da daidaitattun motoci don ware beads ta hanyar bayani da canja wurin zuwa silos daban-daban.

(5) shafi

A yayin samar da EPS, ajiya, sufuri da tsari, tseren mai hurawa ba makawa ba makawa. Idan mai busa mai ƙarfi da yawa rasa, matsaloli da yawa za su faru, kamar raguwar faɗaɗa na EPS, da sauransu don tsawaita lokacin hurawa, da amfani da wakili a farfajiya na EPS yana da mahimmanci.

Harka

Tare da Donghenhen ya jagoranci hanya, makomar allurar rigakafin ƙwararrun nuna yiwuwar yiwuwar da ba ta dace ba, suna aiwatar da Outlook don masana'antar. Kasance tare da mu yayin da muke ci gaba da kirkirar da kuma juyar da eps albarkatun samar da kayan aikin EPS. A ƙarshe, yanayin allurar Styroofoam a cikin Finikin EPS Raw kayan aikin ƙasa na Dongashen duniya yana aiki azaman aikin masana'antu. Muna aiki mai ƙarfi mai inganci, ƙwarewar fasaha don isar da fifikon haɓakar kayan ga abokanmu da abokan ciniki. Bincika abubuwan al'ajabi na styroofoam allurar gyara tare da Donghenhhhen yau.