Good Wholesale Vendors Eps Insulation Panel Molding Machine - Polystyrene block moulding machine with vacuum – DONGSHEN

Good Wholesale Vendors Eps Insulation Panel Molding Machine - Polystyrene block moulding machine with vacuum – DONGSHENDetail:

Product Details

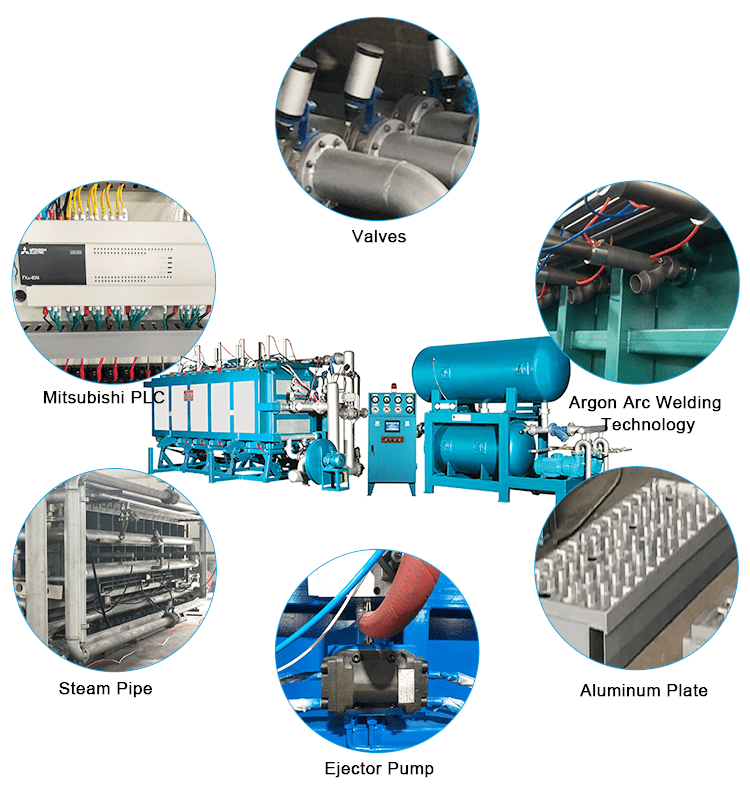

Polystyrene block moulding machine with vacuum advantages:

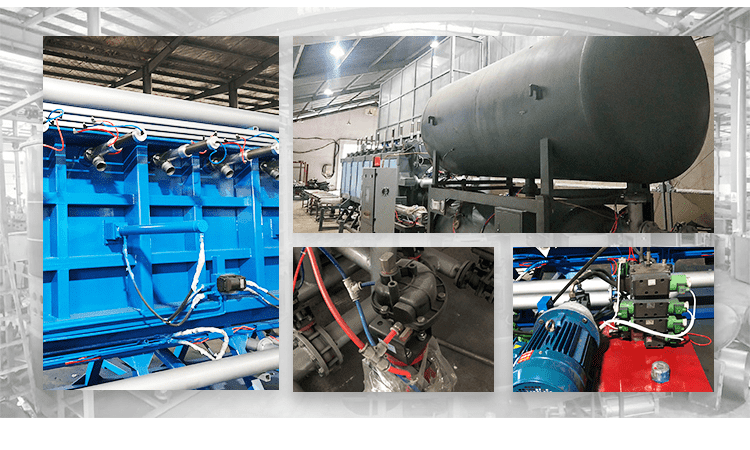

1.Machine is made of high-strength square tubes and thick steel plates;

2.Machine uses 5mm thick aluminum steam plates with Teflon coating. And under aluminum plate, bigger sized supports at more quantity are placed to avoid aluminum plate deform under high pressure. Aluminum plates doesn’t change form after ten years working;

3.Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

4.Machine with more steam lines to ensure steaming even in blocks, so block fusion is better;

5.Machine plates are with better drainage system so blocks are more dried and can be cut in short time;

6.All machine plates through rust removing, ball spraying, then do anti-rust base painting and surface painting, so machine body is not easy to get rusted;

7.Machine use smart piping system and steaming process, ensuring good fusion of blocks both for high density and low density;

8.Fast filling system and efficient vacuum system ensures machine fast working, each block 4~8 minutes;

9.Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

10.Most components used in the machine are imported or famous branded products.

Main Technical Parameters

Item | Unit | PB2000V | PB3000V | PB4000V | PB6000V | |

Mould Cavity Size | mm | 2040*1240*1030 | 3060*1240*1030 | 4080*1240*1030 | 6100*1240*1030 | |

Block Size | mm | 2000*1200*1000 | 3000*1200*1000 | 4000*1200*1000 | 6000*1200*1000 | |

Steam | Entry | Inch | 2’’(DN50) | 2’’(DN50) | 6’’(DN150) | 6’’(DN150) |

Consumption | Kg/cycle | 25~45 | 45~65 | 60~85 | 95~120 | |

Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | |

Compressed Air | Entry | Inch | 1.5’’(DN40) | 1.5’’(DN40) | 2’’(DN50) | 2’’(DN50) |

Consumption | m³/cycle | 1.5~2 | 1.5~2.5 | 1.8~2.5 | 2~3 | |

Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | |

Vacuum Cooling Water | Entry | Inch | 1.5’’(DN40) | 1.5’’(DN40) | 1.5’’(DN40) | 1.5’’(DN40) |

Consumption | m³/cycle | 0.4 | 0.6 | 0.8 | 1 | |

Pressure | Mpa | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | |

Drainage | Vacuum Drain | Inch | 4’’(DN100) | 5’’(DN125) | 5’’(DN125) | 6’’(DN150) |

Down Steam Vent | Inch | 4’’(DN100) | 5’’(DN125) | 6’’(DN150) | 6’’(DN150) | |

Air Cooling Vent | Inch | 4’’(DN100) | 4’’(DN100) | 6’’(DN150) | 6’’(DN150) | |

Capacity 15kg/m³ | Min/cycle | 4 | 5 | 7 | 8 | |

Connect Load/Power | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Overall Dimension (L*H*W) | mm | 5700*4000*2800 | 7200*4500*3000 | 11000*4500*3000 | 12600*4500*3100 | |

Weight | Kg | 5000 | 6500 | 10000 | 14000 | |

Case

Related video

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand ofGood Wholesale Vendors Eps Insulation Panel Molding Machine - Polystyrene block moulding machine with vacuum – DONGSHEN, The product will supply to all over the world, such as: Germany, Berlin, San Francisco, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.