Foam Box Mould Supplier - High-Quality EPS Moulds

Product Main Parameters

| Steam Chamber | Mould Size | Patterning | Machining | Alu Alloy Plate Thickness | Packing | Delivery |

|---|---|---|---|---|---|---|

| 1200*1000mm | 1120*920mm | Wood or PU by CNC | Fully CNC | 15mm | Plywood box | 25~40days |

| 1400*1200mm | 1320*1120mm | Wood or PU by CNC | Fully CNC | 15mm | Plywood box | 25~40days |

| 1600*1350mm | 1520*1270mm | Wood or PU by CNC | Fully CNC | 15mm | Plywood box | 25~40days |

| 1750*1450mm | 1670*1370mm | Wood or PU by CNC | Fully CNC | 15mm | Plywood box | 25~40days |

Common Product Specifications

| Material | High-Quality Aluminum Alloy |

|---|---|

| Mould Frame | Extruded Aluminum Alloy Profile |

| Processing | Fully CNC Machined |

| Coating | Teflon for Easy Demoulding |

| Applications | Electronics Packaging, Automotive Parts, Food & Beverage, Construction |

| Delivery Time | 25~40 days |

Product Manufacturing Process

The manufacturing process of a Foam Box Mould involves design, prototyping, and precise machining to ensure high-quality output. Initially, the mould design is created using advanced CAD software. Once the design is finalized, high-quality aluminum alloy plates are used, typically ranging from 15mm to 20mm in thickness. CNC machines process the moulds, ensuring a tolerance within 1mm. Post-machining, the moulds are coated with Teflon for easy demoulding. A thorough quality control process is applied at each step, from patterning and casting to assembling and coating, ensuring the final product meets high standards.

Product Application Scenarios

Foam Box Moulds find extensive applications across various industries. In the electronics sector, these moulds help create custom packaging solutions that provide cushioning and protection against shocks during transit. The automotive industry uses foam moulds for insulation and noise reduction components. In the food and beverage industry, foam boxes ensure temperature stability and protection during transportation. Construction applications include using foam for insulation and structural purposes, where custom shapes and forms are required. These versatile applications underscore the importance of high-quality Foam Box Moulds in modern manufacturing and packaging.

Product After-Sales Service

We offer comprehensive after-sales service, including technical support, maintenance assistance, and prompt resolution of any issues. Our team is available to provide guidance on installation, operation, and maintenance to ensure optimal performance of the moulds. We also offer spare parts and refurbishment services to extend the lifespan of your moulds. Customer satisfaction is our priority, and we strive to address any concerns promptly and efficiently.

Product Transportation

The moulds are securely packed in plywood boxes to prevent damage during transit. We coordinate with reliable logistics partners to ensure timely and safe delivery of your moulds. Tracking information is provided, and we assist with customs clearance if required. Our packaging and shipping processes are designed to protect the moulds and ensure they reach you in perfect condition.

Product Advantages

- High Precision: Fully CNC machined with a tolerance within 1mm.

- Durable Material: Made from high-quality aluminum alloy plates.

- Easy Demoulding: Teflon coating on all cavities and cores.

- Fast Delivery: Quick turnaround time of 25~40 days.

- Customizable: Tailored designs to meet specific client requirements.

Product FAQ

1. What materials are used for the foam box moulds?

We use high-quality aluminum alloy for the mould plates, ensuring durability and precision.

2. What is the typical delivery time for a foam box mould?

The standard delivery time ranges from 25 to 40 days, depending on the complexity and customization required.

3. How do you ensure the quality of the moulds?

We implement strict quality control at every stage, from design and machining to assembly and coating, ensuring high standards are maintained.

4. Can you customize the moulds based on specific requirements?

Yes, we offer customized mould designs to cater to specific client needs, including unique shapes and sizes.

5. What after-sales services do you provide?

We offer technical support, maintenance assistance, and spare parts to ensure optimal performance and longevity of the moulds.

6. How do you handle shipping and transportation?

The moulds are packed in sturdy plywood boxes and shipped via reliable logistics partners. We provide tracking information and assist with customs clearance if needed.

7. Are the moulds easy to use and maintain?

Yes, our moulds are designed for ease of use and maintenance, with features like Teflon coating for easy demoulding and durable construction for long-lasting performance.

8. What industries typically use your foam box moulds?

Our foam box moulds are used in various industries, including electronics packaging, automotive parts, food and beverage, and construction.

9. Do you provide training for using the moulds?

Yes, we offer training and detailed instructions for the installation, operation, and maintenance of the moulds to ensure optimal usage.

10. Can you convert customer’s samples to CAD drawings?

Yes, we can convert customer’s samples to CAD or 3D drawings to create precise mould designs based on the provided samples.

Product Hot Topics

1. High Precision CNC Machined Foam Box Moulds

Our foam box moulds are machined with high precision using CNC technology, ensuring a tolerance within 1mm. This precision guarantees that each foam box produced using our moulds meets exact specifications, providing reliability and consistency in your production line. As a leading supplier of Foam Box Moulds, we continuously invest in the latest CNC technologies and skilled engineers to maintain our high standards.

2. Custom Designs Tailored to Your Needs

At Dongshen, we understand that different industries and applications have unique requirements. That's why we offer customized mould designs tailored to meet your specific needs. Whether you need moulds for electronics packaging, automotive parts, or food and beverage containers, our expert team can create the perfect solution. Trust us as your Foam Box Mould supplier to deliver moulds that fit your exact specifications.

3. Durable and Long-Lasting Mould Materials

Our moulds are made from high-quality aluminum alloy plates, ensuring durability and longevity. The robust material can withstand the high pressures and temperatures of the foam moulding process without compromising the integrity of the end product. As a trusted supplier of Foam Box Moulds, we prioritize the use of premium materials to provide moulds that stand the test of time and deliver consistent results.

4. Quick and Reliable Delivery

We understand the importance of timely delivery in maintaining efficient production schedules. That’s why we offer a quick turnaround time of 25~40 days for our foam box moulds. As a reliable supplier, we strive to meet our delivery commitments and keep your production line running smoothly. Our streamlined processes and dedicated logistics team ensure your moulds arrive on time and in perfect condition.

5. Comprehensive After-Sales Support

Our commitment to customer satisfaction extends beyond the sale. We provide comprehensive after-sales support, including technical assistance, maintenance services, and spare parts supply. Our goal as your Foam Box Mould supplier is to ensure the continuous and optimal performance of your moulds, addressing any issues promptly and effectively.

6. Advanced Teflon Coating for Easy Demoulding

All our moulds feature Teflon coating on the cavities and cores to facilitate easy demoulding. This advanced coating reduces sticking and ensures smooth removal of the foam products from the moulds, enhancing production efficiency. Choose us as your Foam Box Mould supplier to experience the benefits of our innovative mould designs and coatings.

7. Expertise in Various Foam Types

We have extensive experience working with different foam types, including EPS, Polyurethane, Polyethylene, and EVA foams. This expertise allows us to design and manufacture moulds that cater to the specific properties and requirements of each foam type. As a leading Foam Box Mould supplier, we provide versatile solutions for a wide range of applications and industries.

8. Strict Quality Control Measures

Quality is at the core of our manufacturing process. We implement strict quality control measures at every stage, from design and material selection to machining and assembly. Our commitment to quality ensures that each mould meets the highest standards of precision and durability. Trust us as your Foam Box Mould supplier to deliver products that exceed your expectations.

9. Versatile Application Areas

Our foam box moulds are used across various industries, including electronics, automotive, food and beverage, and construction. This versatility highlights the wide-ranging capabilities of our mould designs. As a trusted Foam Box Mould supplier, we understand the diverse needs of different industries and provide tailored solutions to meet those needs effectively.

10. Long-Term Reliability and Performance

Our moulds are designed to offer long-term reliability and performance, ensuring consistent production quality over time. The combination of high-quality materials, precise machining, and innovative coatings results in moulds that deliver exceptional durability and efficiency. As your Foam Box Mould supplier, we are dedicated to providing products that support the long-term success of your business.

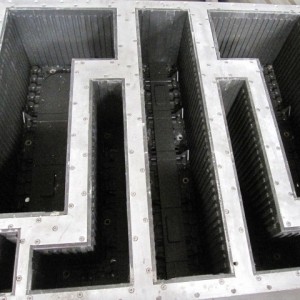

Image Description

There is no picture description for this product