Factory-Ready EPS Injection Moulding Machine

Product Main Parameters

| Item | Unit | FAV1200 | FAV1400 | FAV1600 | FAV1750 |

|---|---|---|---|---|---|

| Mould Dimension | mm | 1200*1000 | 1400*1200 | 1600*1350 | 1750*1450 |

| Max Product Dimension | mm | 1000*800*400 | 1200*1000*400 | 1400*1150*400 | 1550*1250*400 |

| Stroke | mm | 150~1500 | 150~1500 | 150~1500 | 150~1500 |

| Steam Consumption | Kg/cycle | 5~7 | 6~9 | 7~11 | 8~12 |

| Steam Pressure | Mpa | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 |

| Weight | Kg | 5000 | 5500 | 6000 | 6500 |

Common Product Specifications

| Specification | FAV1200 | FAV1400 | FAV1600 | FAV1750 |

|---|---|---|---|---|

| Cooling Water Consumption | 45~130 Kg/cycle | 50~150 Kg/cycle | 55~170 Kg/cycle | 55~180 Kg/cycle |

| Compressed Air Consumption | 1.5 m³/cycle | 1.8 m³/cycle | 1.9 m³/cycle | 2 m³/cycle |

Product Manufacturing Process

The manufacturing process of EPS Injection Moulding Machines follows a series of precise steps ensuring optimal functionality and quality. The process begins with the pre-expansion of EPS beads through pre-expanders, where they are subjected to controlled steam temperatures to increase their size and prepare them for moulding. Following pre-expansion, the material is transported to the EPS Injection Moulding Machine via a hopper and filled into a mould cavity. In this mould, the EPS is again exposed to steam under controlled pressure which causes the beads to expand further and fuse, forming the desired shape. Advanced steam, cooling, and drainage systems in our machines, supported by a robust control interface, ensure efficient production and operation. As the importance of recycling grows, innovations focus on reducing waste and improving material reuse, shaping a sustainable future for EPS manufacturing.

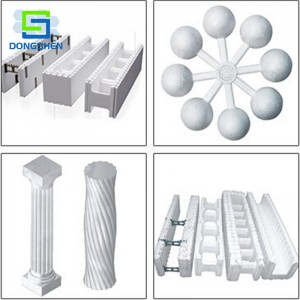

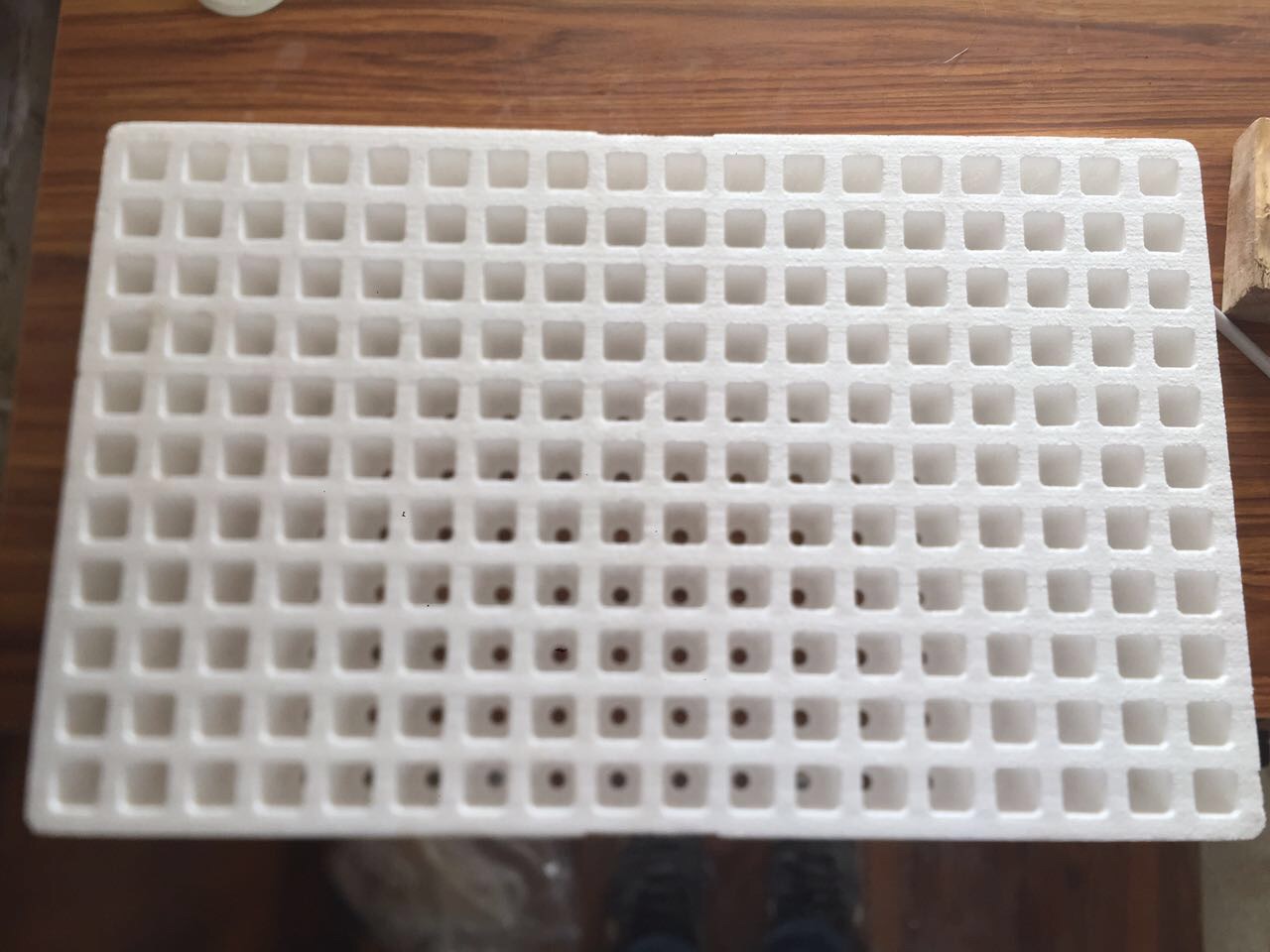

Product Application Scenarios

EPS Injection Moulding Machines are pivotal in various industries due to their versatility and efficiency. In the packaging sector, they are used to produce cushioning elements for fragile electronics, ensuring safe transit and delivery. In construction, due to their excellent insulation properties, they find applications in producing components like insulation panels and lightweight concrete blocks, contributing significantly to energy-efficient building solutions. The automotive industry benefits from EPS for its impact absorption capacity, using it in safety components like helmet linings and car bumpers. As industries strive for sustainable and efficient production methods, the strategic advantages of EPS Injection Moulding Machines make them indispensable in modern factories.

Product After-Sales Service

Our comprehensive after-sales service ensures that your factory receives continuous support post-purchase. We offer regular maintenance, software updates, and training sessions for factory operators to maximize the machine's efficiency and lifespan. In case of any issue, our technical team is ready to provide both remote and onsite assistance.

Product Transportation

We ensure that our EPS Injection Moulding Machines are transported safely and efficiently to your factory location, with full trucking logistics and handling support. Customized packaging solutions minimize the risk of damage during transit.

Product Advantages

- Customizable: Adapt design and production capacity to fit factory requirements.

- Cost-Effective: Designed for high efficiency, reducing operating costs.

- Advanced Control Systems: Enhances precision and operational control.

- Environmentally Conscious: Supports recycling and minimizes waste.

Product FAQ

- How do EPS Injection Moulding Machines benefit my factory? EPS Injection Moulding Machines offer high precision, efficiency, and productivity, essential for meeting factory demands efficiently.

- Is it easy to maintain the EPS Injection Moulding Machine? Yes, our machines are designed for easy maintenance, with user-friendly interfaces for quick diagnostics and troubleshooting.

- Can the machine be customized for specific factory needs? Absolutely, we can adapt the machine's design and configuration to match the production requirements of your factory.

- What is the lifespan of an EPS Injection Moulding Machine? With proper maintenance, our machines are built to last, delivering reliable performance for over a decade in factory settings.

- How energy-efficient are these machines? Our machines incorporate advanced technologies to minimize energy consumption while maximizing production efficiency in the factory.

- What training is provided with the machine? We offer comprehensive training programs to ensure your factory staff is proficient in operating and maintaining the equipment.

- How does the after-sales support work? Our after-sales package includes regular maintenance checks, software updates, and technical support to ensure smooth factory operations.

- What materials can be used in the EPS Injection Moulding Machine? The machine is optimized for EPS materials, catering to a variety of factory production requirements.

- Can the machine handle bulk production orders? Yes, our machines are designed for high-volume production, catering to large-scale factory needs efficiently.

- What if we require spare parts? Spare parts are readily available and can be dispatched quickly to minimize downtime in your factory.

Product Hot Topics

- The Future of Factories with EPS Injection Moulding Machines With advancements in technology, EPS Injection Moulding Machines are revolutionizing how factories operate. Their efficiency and precision are enabling companies to produce high-quality, cost-efficient products while reducing waste. As sustainable practices become a priority, these machines' adaptability to environmentally-friendly materials positions them as a key asset in modern manufacturing.

- Enhancing Factory Efficiency with Custom EPS Solutions Factories implementing EPS Injection Moulding Machines witness a significant boost in productivity. By allowing for machine customization, we ensure that your production line is tailored to meet specific needs while maintaining high quality. This customization not only streamlines operations but also reduces material waste, showcasing the versatility of EPS technology in factory settings.

- Sustainability in Factory Production with EPS Technology As environmental concerns rise, factories are turning to EPS Injection Moulding Machines for their recyclable materials and energy-efficient processes. These machines are not only reducing manufacturing costs but are also leading the way in sustainable factory operations by promoting the use of recycled materials and reducing carbon footprints.

- Cost-Effective Manufacturing with EPS Injection Moulding Machines By integrating EPS Injection Moulding Machines, factories can significantly cut production costs. The machines' efficient use of materials and energy translates into lower operational expenses, enabling companies to reinvest savings into other factory enhancements and innovations.

- EPS Injection Moulding Machines: The Backbone of Modern Factories These machines stand as a testament to modern industrial progress. Their integration into factory floors proves instrumental in developing a streamlined, efficient production process, helping factories meet increasing demands with precision and speed.

- Revolutionizing Traditional Factories with EPS Technology Traditional manufacturing paradigms are fast evolving with the advent of EPS Injection Moulding Machines. These machines are enabling factories to pivot towards more versatile, responsive production lines, shedding light on the future of adaptive manufacturing.

- The Role of EPS Injection Moulding Machines in Global Manufacturing Across the globe, factories are adopting EPS Injection Moulding Machines to keep pace with international production standards. This transition is not only enhancing production capabilities but also placing factories at the forefront of manufacturing innovation.

- Factory Scalability and EPS Injection Moulding Machines Factories looking to scale quickly find EPS Injection Moulding Machines invaluable. Their scalability allows factories to expand production lines without compromising on quality, making them crucial for rapid growth and adaptation.

- Optimizing Factory Layout with EPS Technology EPS Injection Moulding Machines require thoughtful factory layout planning, maximizing space and production efficiency. This optimization leads to seamless operations, ensuring that factories remain competitive and productive.

- Integrating EPS Injection Moulding Machines into Factory Workflow The integration process is critical for successful adoption of EPS Injection Moulding Machines in factories. By aligning these machines with existing workflows, factories can achieve greater efficiency and output, setting new benchmarks in factory performance.

Image Description

There is no picture description for this product