Factory Direct Ice Box Mold for Premium Beverage Presentation

Product Main Parameters

| Parameter | Value |

|---|---|

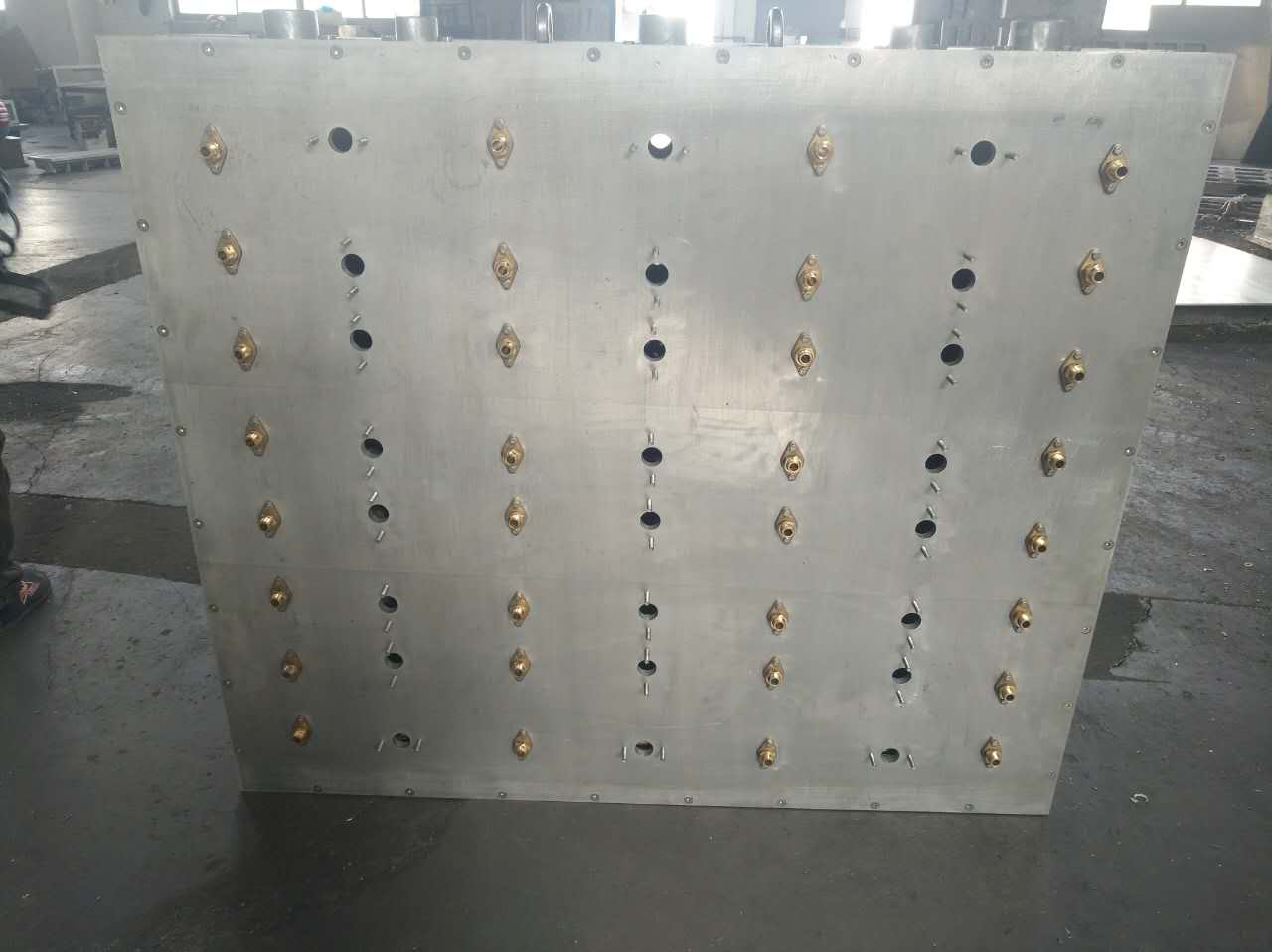

| Mold Material | High-Quality Aluminum |

| Plate Thickness | 15mm - 20mm |

| Steam Chamber | 1200*1000mm, 1400*1200mm, 1600*1350mm, 1750*1450mm |

| Mold Size | 1120*920mm, 1320*1120mm, 1520*1270mm, 1670*1370mm |

| Machining | Fully CNC |

| Packing | Plywood Box |

| Delivery Time | 25~40 days |

Common Product Specifications

| Specification | Detail |

|---|---|

| Material | Silicone, Plastic, Stainless Steel |

| Shapes Available | Standard Cube, Spherical, Novelty, Clear Ice, Large Block |

| Use Cases | Beverage Presentation, Culinary Uses, Medical and Scientific Applications |

Product Manufacturing Process

According to authoritative sources, the manufacturing process for Ice Box Molds involves multiple stages to ensure high quality and precision. Initially, high-quality aluminum ingots are selected and cast into rough shapes. These castings are then subjected to CNC machining to achieve precise dimensions and smooth surfaces. Teflon coating is applied to ensure easy demoulding. Quality control checks are performed at various stages to ensure the final product meets stringent standards. This meticulous process results in Ice Box Molds that are durable and efficient, suitable for both commercial and domestic uses.

Product Application Scenarios

As per authoritative papers, Ice Box Molds are utilized in a wide variety of scenarios. In the beverage industry, they are used to create visually appealing ice for cocktails and other drinks, enhancing the customer experience. Culinary professionals use these molds to create intricate ice shapes for seafood platters, chilled desserts, and more. In medical and scientific fields, uniform ice shapes are crucial for experiments and procedures requiring precise temperature control. The versatility of Ice Box Molds makes them indispensable across multiple industries.

Product After-Sales Service

We offer comprehensive after-sales service, including technical support and troubleshooting. Clients can contact us via email or phone for prompt assistance. We also provide a warranty for material and workmanship defects.

Product Transportation

Our Ice Box Molds are securely packed in plywood boxes to prevent damage during transit. We offer various shipping options depending on client preferences and location to ensure timely and safe delivery.

Product Advantages

- High-quality aluminum material ensures durability and longevity.

- Fully CNC machined for precise dimensions and smooth surfaces.

- Teflon coating guarantees easy demoulding.

- Experienced engineering team capable of custom designs.

- Quick delivery and thorough testing before shipment.

Product FAQ

1. What materials are used in manufacturing these molds?

The Ice Box Molds are made from high-quality aluminum, silicone, plastic, and stainless steel, ensuring durability and efficient performance.

2. Can I request custom shapes and sizes?

Yes, our factory offers customization options based on your specific needs for shapes and sizes.

3. How long does it take to deliver?

The typical delivery time ranges from 25 to 40 days, depending on the complexity and customization of the Ice Box Mold.

4. What is the thickness of the aluminum plates used?

The aluminum plates have a thickness ranging from 15mm to 20mm, providing robustness and longevity.

5. Is there a warranty provided?

Yes, we provide a warranty for defects in material and workmanship as part of our after-sales service.

6. How do I clean the molds?

Certain models, especially silicone ones, are dishwasher-safe. For others, hand washing with mild detergent is recommended to maintain their quality.

7. What are the main applications of these molds?

Our Ice Box Molds are widely used in beverage presentation, culinary creations, and even in medical and scientific applications.

8. Can these molds be easily demolded?

Yes, thanks to the Teflon coating, our molds provide easy demoulding without sticking or breaking.

9. How precise are the mold dimensions?

Our molds are fully CNC machined, ensuring a tolerance within 1mm for high precision and quality.

10. Do you provide support for setting up a new factory?

Yes, we offer comprehensive support for setting up new EPS factories, including design, machinery, and technical aid.

Product Hot Topics

1. How does the factory ensure the quality of Ice Box Molds?

At our factory, the quality of Ice Box Molds is ensured through strict quality control measures at every stage of production. We select high-quality materials, employ CNC machining for precision, and apply Teflon coating for easy demoulding. Extensive testing and checks are performed before delivery to ensure each mold meets the highest standards.

2. What makes the Ice Box Molds from this factory unique?

Our Ice Box Molds are unique due to their high-quality construction from first-class aluminum, precision CNC machining, and durable Teflon coating. Additionally, our experienced engineering team can design custom molds based on specific client needs, making them highly versatile and reliable for various applications.

3. Can the factory customize Ice Box Molds for different industries?

Yes, our factory specializes in customizing Ice Box Molds to meet the specific needs of various industries. Whether for high-end beverage presentations, culinary uses, or scientific applications, we can design and manufacture molds that meet the precise requirements of each industry.

4. How does the factory support clients in setting up new EPS factories?

We provide comprehensive support for clients setting up new EPS factories. Our services include designing the factory layout, supplying machinery, and offering technical assistance. Our aim is to help clients optimize their production processes, reduce energy consumption, and increase overall efficiency.

5. What are the common shapes produced by the factory’s Ice Box Molds?

The factory offers a wide variety of shapes including standard cubes, spheres, novelty designs, clear ice molds, and large blocks. These shapes are designed to meet different application needs from everyday use to specialized requirements in high-end dining and scientific research.

6. How does the factory handle after-sales service for Ice Box Molds?

Our factory offers a comprehensive after-sales service, including technical support and troubleshooting. Clients can easily reach us via email or phone for prompt assistance. We also provide a warranty for any defects in material or workmanship, ensuring customer satisfaction.

7. What materials are used by the factory to manufacture Ice Box Molds?

We use high-quality materials such as aluminum, silicone, plastic, and stainless steel. Each material offers unique benefits, from flexibility and ease of use to durability and precision, ensuring our molds meet diverse client needs.

8. What is the typical delivery time for Ice Box Molds from the factory?

The typical delivery time for our Ice Box Molds ranges from 25 to 40 days. This timeframe allows us to ensure each mold is crafted to the highest standards and thoroughly tested before shipment.

9. How does the factory ensure easy demoulding of ice shapes?

Easy demoulding is ensured through the application of a durable Teflon coating on our Ice Box Molds. This coating prevents the ice from sticking to the mold, allowing for smooth and effortless removal of ice shapes.

10. Can the factory convert customer samples into CAD or 3D drawings?

Yes, our experienced engineers can convert customer samples into precise CAD or 3D drawings. This capability allows us to create customized molds that meet specific client requirements, ensuring a perfect fit and optimal performance.

Image Description

There is no picture description for this product