Experience Premium Efficiency with the XPS Foam Cutter EPS Machine

Product Details

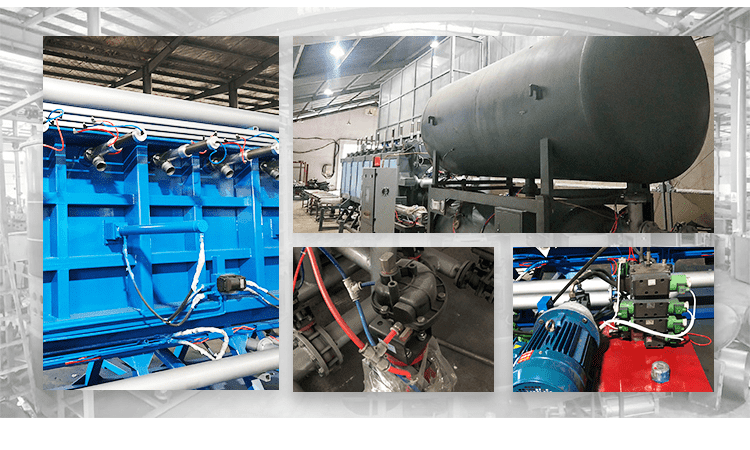

EPS insulation sheets makig machine is an efficient EPS machine to make EPS blocks. EPS blocks can be cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc.

EPS insulation sheets makig machine can produce high density EPS blocks, working in fast cycle, and all blocks are straight and strong and with low water moisture. The machine can also make low density blocks with good quality. It can make high density at 40g/l and low density at 4g/l.

EPS insulation sheets makig machine complete with main machine body, control box, vacuum system, weighing system etc.

EPS insulation sheets makig machine advantages:

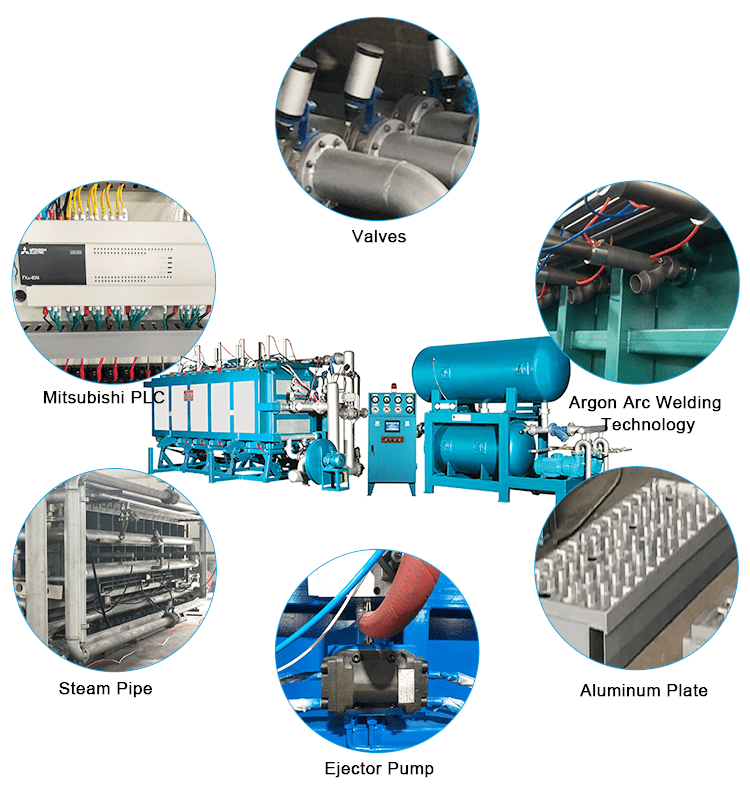

1.Machine is made of high-strength square tubes and thick steel plates;

2.Machine uses 5mm thick aluminum steam plates with Teflon coating. And under aluminum plate, bigger sized supports at more quantity are placed to avoid aluminum plate deform under high pressure. Aluminum plates doesn’t change form after ten years working;

3.Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

4.Machine with more steam lines to ensure steaming even in blocks, so block fusion is better;

5.Machine plates are with better drainage system so blocks are more dried and can be cut in short time;

6.All machine plates through rust removing, ball spraying, then do anti-rust base painting and surface painting, so machine body is not easy to get rusted;

7.Machine use smart piping system and steaming process, ensuring good fusion of blocks both for high density and low density;

8.Fast filling system and efficient vacuum system ensures machine fast working, each block 4~8 minutes;

9.Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

10.Most components used in the machine are imported or famous branded products.

Main Technical Parameters

|

Item |

Unit |

PB2000V |

PB3000V |

PB4000V |

PB6000V |

|

|

Mould Cavity Size |

mm |

2040*1240*1030 |

3060*1240*1030 |

4080*1240*1030 |

6100*1240*1030 |

|

|

Block Size |

mm |

2000*1200*1000 |

3000*1200*1000 |

4000*1200*1000 |

6000*1200*1000 |

|

|

Steam |

Entry |

Inch |

2’’(DN50) |

2’’(DN50) |

6’’(DN150) |

6’’(DN150) |

|

Consumption |

Kg/cycle |

25~45 |

45~65 |

60~85 |

95~120 |

|

|

Pressure |

Mpa |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

|

|

Compressed Air |

Entry |

Inch |

1.5’’(DN40) |

1.5’’(DN40) |

2’’(DN50) |

2’’(DN50) |

|

Consumption |

m³/cycle |

1.5~2 |

1.5~2.5 |

1.8~2.5 |

2~3 |

|

|

Pressure |

Mpa |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

0.6~0.8 |

|

|

Vacuum Cooling Water |

Entry |

Inch |

1.5’’(DN40) |

1.5’’(DN40) |

1.5’’(DN40) |

1.5’’(DN40) |

|

Consumption |

m³/cycle |

0.4 |

0.6 |

0.8 |

1 |

|

|

Pressure |

Mpa |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

|

|

Drainage |

Vacuum Drain |

Inch |

4’’(DN100) |

5’’(DN125) |

5’’(DN125) |

6’’(DN150) |

|

Down Steam Vent |

Inch |

4’’(DN100) |

5’’(DN125) |

6’’(DN150) |

6’’(DN150) |

|

|

Air Cooling Vent |

Inch |

4’’(DN100) |

4’’(DN100) |

6’’(DN150) |

6’’(DN150) |

|

|

Capacity 15kg/m³ |

Min/cycle |

4 |

5 |

7 |

8 |

|

|

Connect Load/Power |

Kw |

19.75 |

23.75 |

24.5 |

32.25 |

|

|

Overall Dimension (L*H*W) |

mm |

5700*4000*2800 |

7200*4500*3000 |

11000*4500*3000 |

12600*4500*3100 |

|

|

Weight |

Kg |

5000 |

6500 |

10000 |

14000 |

|

Case

Related video

The XPS Foam Cutter is more than just a machine; it’s a solution that improves your productivity and streamlines your manufacturing process. Utilizing this revolutionary machine, you can produce high-quality EPS insulation sheets, contributing significantly to energy conservation and sustainability. Its precise cutting technology ensures the highest quality production, amplifying the value you deliver to your customers. When it comes to crafting EPS insulation sheets, the XPS Foam Cutter is undeniably the most efficient tool in the industry. It’s time to enhance your production line with the speed and precision you’ve always hoped to achieve. Choose the XPS Foam Cutter, the quintessential machine designed to meet your EPS insulation sheet production needs.