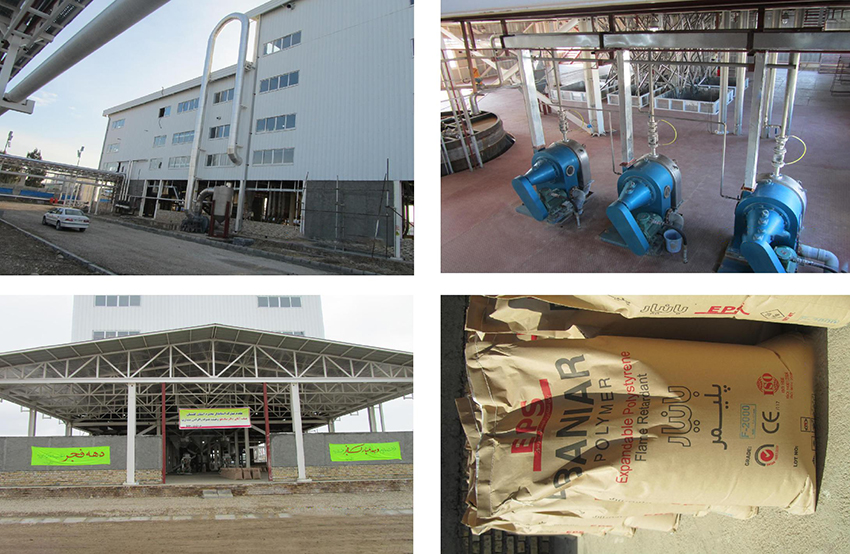

EPS Resin Manufacturer - Raw Material Project

EPS Raw Material Project Details

Product Main Parameters

| Parameter | Specification |

|---|---|

| Polymer Type | Polystyrene |

| Blowing Agent | Pentane |

| Density | 10-30 kg/m3 |

| Thermal Conductivity | 0.032-0.038 W/m·K |

| Moisture Resistance | High |

| Chemical Resistance | High |

Common Product Specifications

| Specification | Detail |

|---|---|

| Bead Size Range | 0.3-2.5 mm |

| Expansion Ratio | 20-40 times |

| Packaging | 25 kg bags or bulk |

| Production Capacity | 500-2000 tons/year |

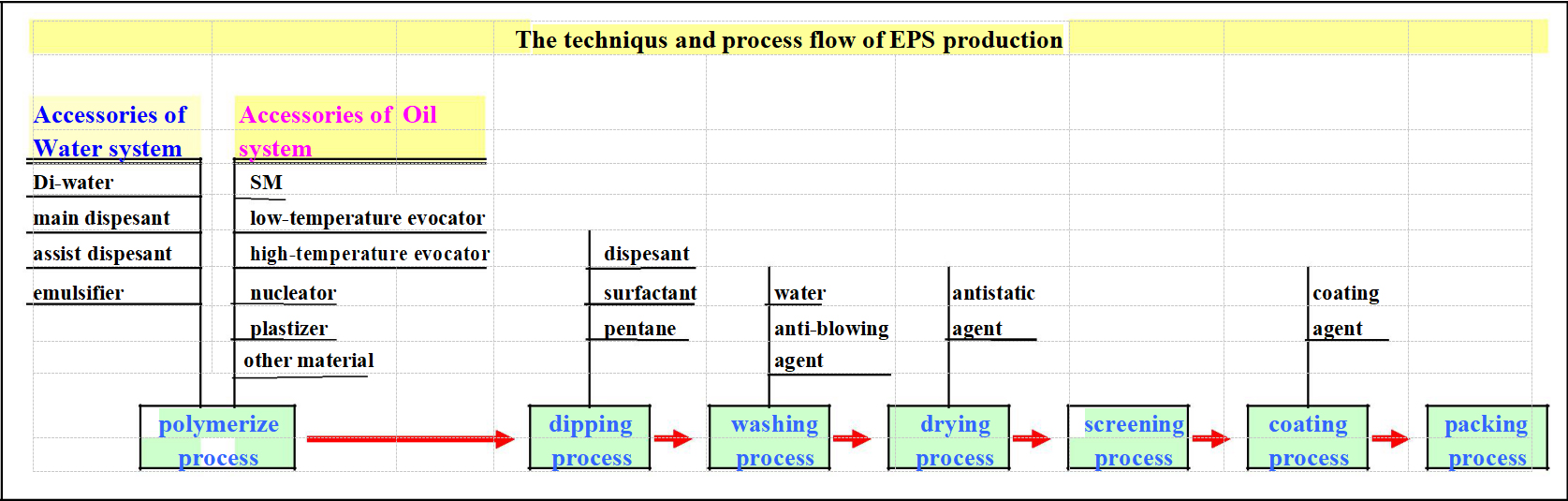

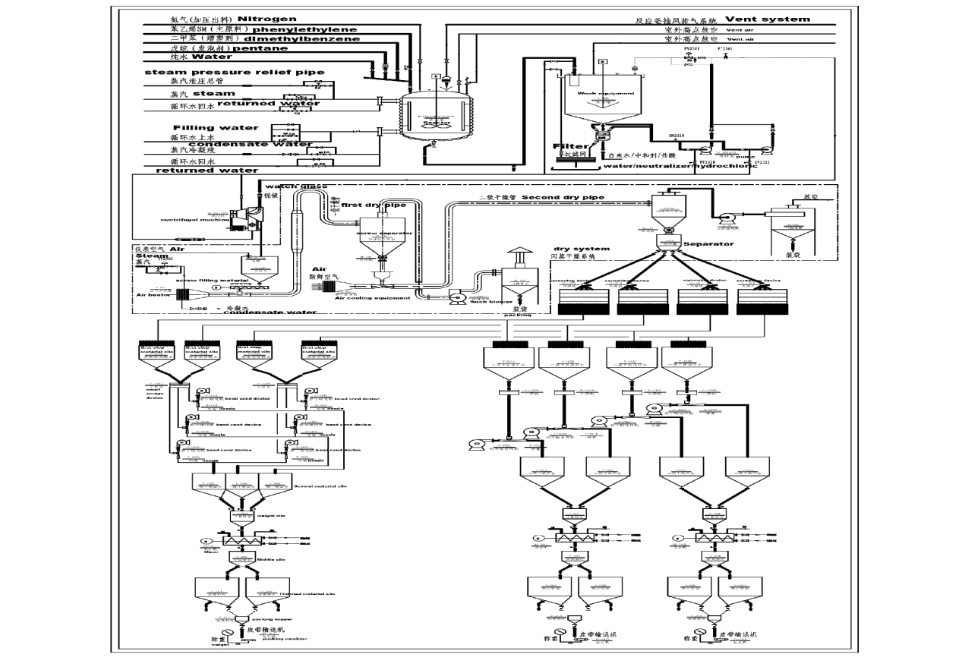

Product Manufacturing Process

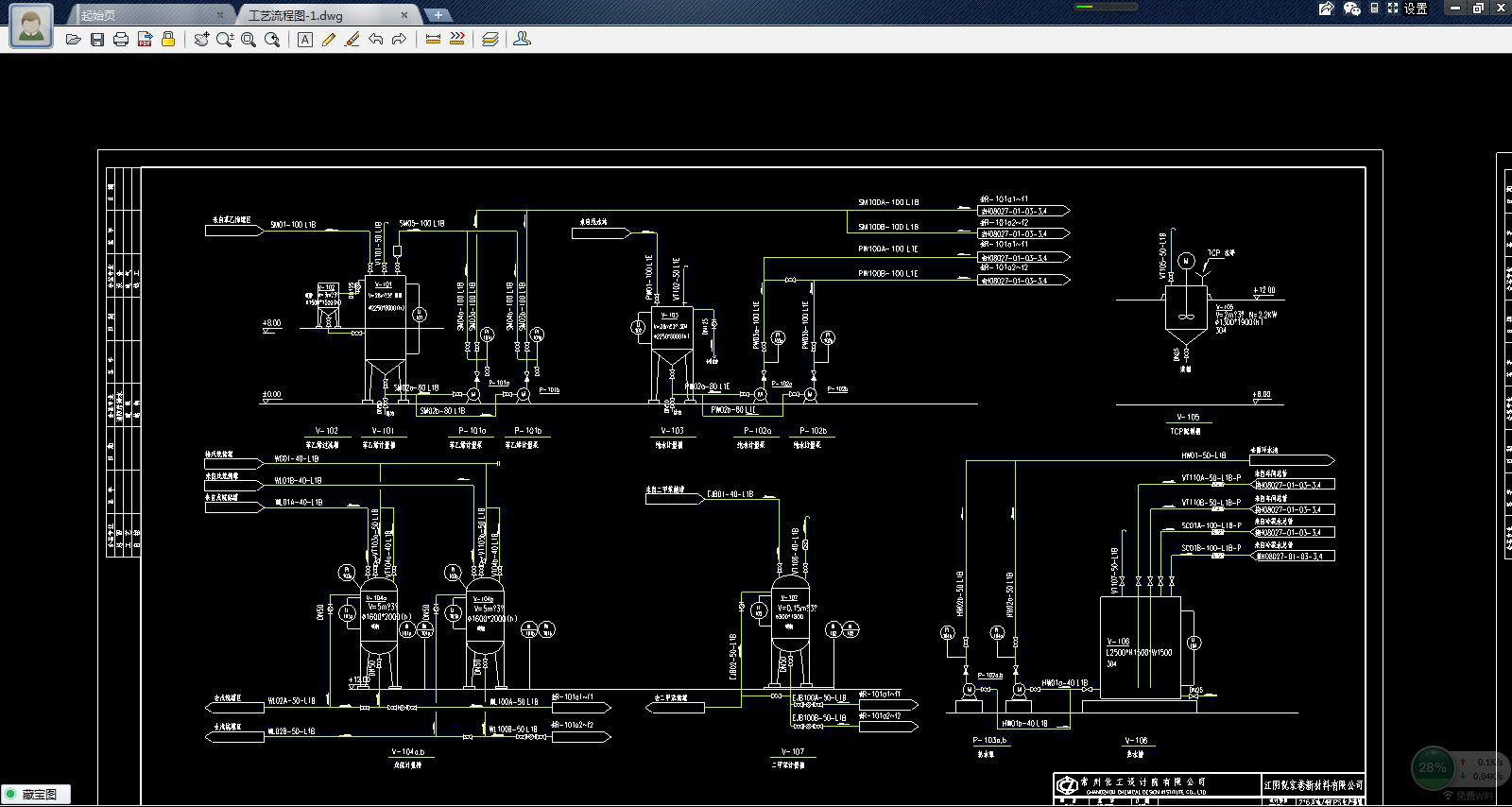

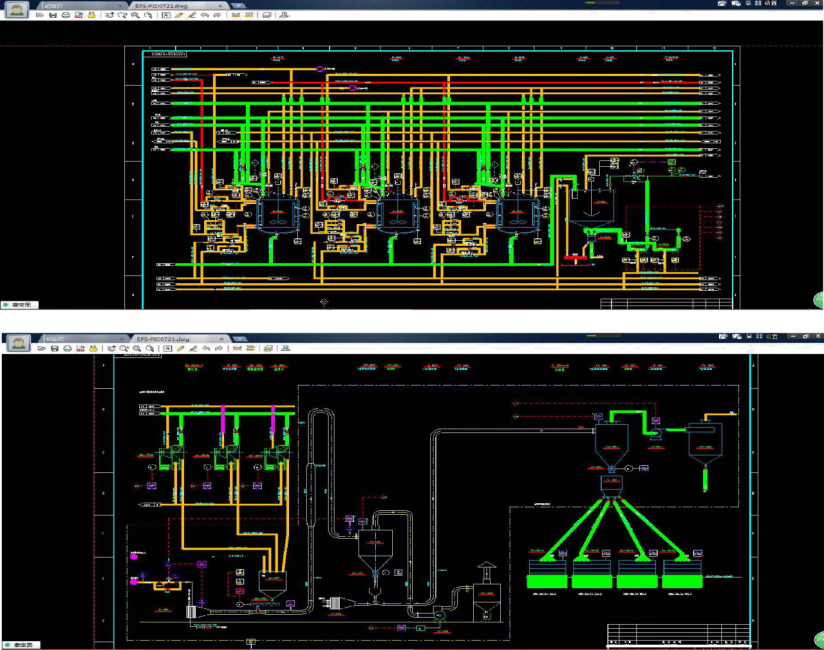

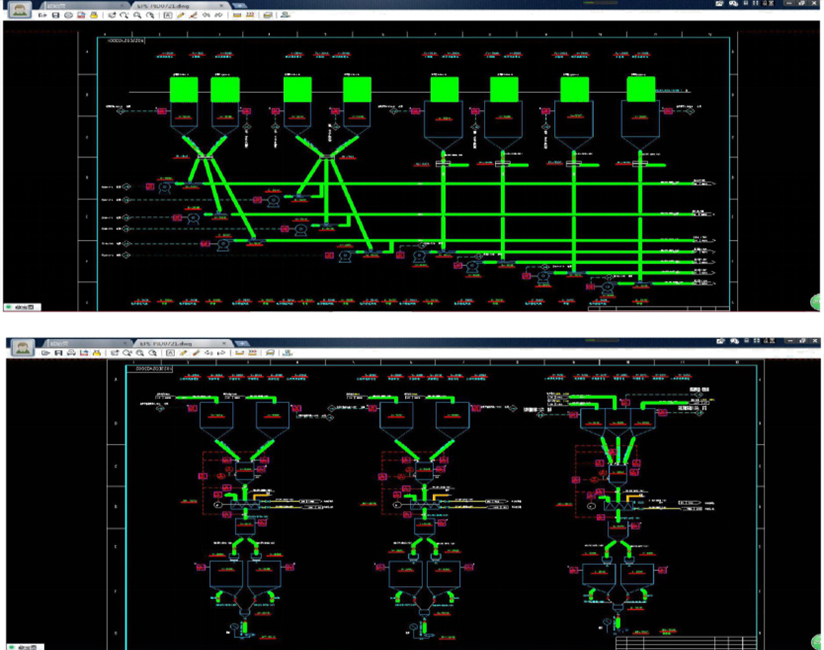

EPS resin manufacturing involves several stages, including polymerization, impregnation, cooling, washing, drying, sieving, and coating. The process starts with polymerizing styrene into polystyrene beads, followed by impregnation with a blowing agent like pentane. These beads expand when exposed to steam. After expansion, the beads are dried and sieved to ensure uniformity. The entire cycle takes approximately 16-17 hours. The final product is a lightweight, moisture-resistant material with excellent insulation properties, ideal for numerous industrial applications.

Product Application Scenarios

EPS resin is widely used in packaging, construction, and other industries due to its unique properties. In the packaging industry, it provides cushioning and thermal insulation for electronics, perishable goods, and delicate items. In construction, EPS resin is used for building insulation, including roof, wall, and foundation insulation, significantly improving energy efficiency. Other applications include the production of surfboards, flotation devices, lightweight concrete, arts and crafts, architectural models, and stage sets.

Product After-Sales Service

We offer comprehensive after-sales services, including technical support, troubleshooting, and spare parts supply. Our dedicated team is available to assist you with any issues and ensure smooth operation of your EPS production line.

Product Transportation

Our EPS resin products are securely packaged in 25 kg bags or in bulk, depending on customer requirements. We ensure safe and timely delivery through reliable logistics partners. Special care is taken to prevent damage during transit.

Product Advantages

- Lightweight and easy to handle

- Excellent thermal insulation properties

- High impact resistance

- Superior moisture and chemical resistance

- Versatile and easily moldable

Product FAQ

- What is EPS resin made of?

EPS resin is made from polystyrene, a synthetic aromatic hydrocarbon polymer derived from the monomer styrene. - What are the main applications of EPS resin?

EPS resin is primarily used in packaging, construction, and various other industries for its insulation, impact resistance, and lightweight properties. - How is EPS resin environmentally friendly?

While EPS resin is non-biodegradable, it can be recycled. Advanced recycling techniques like thermal densification help reduce its environmental impact. - What is the expansion ratio of EPS beads?

The expansion ratio of EPS beads ranges from 20 to 40 times their original size. - What is the typical density of EPS resin?

The density of EPS resin typically ranges from 10 to 30 kg/m3. - How is the quality of EPS resin controlled?

Quality control is maintained through rigorous testing during various production stages, including polymerization, impregnation, and drying. - What are the packaging options for EPS resin?

EPS resin is available in 25 kg bags or bulk packaging. - What is the thermal conductivity of EPS resin?

EPS resin has a thermal conductivity of 0.032-0.038 W/m·K. - Can EPS resin be custom-made?

Yes, EPS resin can be customized according to specific requirements, including bead size and expansion ratio. - What after-sales services are available?

We offer technical support, troubleshooting, and spare parts supply to ensure smooth operation of your EPS production line.

Product Hot Topics

- How Does an EPS Resin Manufacturer Ensure Product Quality?

Ensuring the quality of EPS resin involves meticulous monitoring at every stage of production. Starting with high-grade raw styrene, continuous quality checks are performed through polymerization, impregnation, and the final expansion stages. State-of-the-art DCS systems control temperature and pressure, ensuring a consistent product. Regular sample observations and adjustments further guarantee that all EPS beads meet the required specifications.

- What Are the Environmental Impacts of EPS Resin?

EPS resin, being non-biodegradable, has raised environmental concerns due to its persistence in the ecosystem. However, many EPS resin manufacturers are investing in recycling programs to address this issue. Techniques like thermal densification reduce the volume of EPS waste, allowing it to be repurposed. Ongoing research aims to develop more sustainable practices and materials within the industry.

- EPS Resin Manufacturer: Advancements in Technology

Technological advancements have significantly impacted EPS resin production. Modern EPS resin manufacturers employ automated systems that enhance precision and efficiency. Innovations in chemical formulations and production methods are continually improving the material’s properties, such as its thermal insulation and impact resistance, broadening its application scope.

- Why Choose an EPS Resin Manufacturer for Your Construction Needs?

Choosing a specialized EPS resin manufacturer for construction materials ensures access to high-quality, customized products. EPS resin’s excellent thermal insulation and moisture resistance make it ideal for building applications, reducing energy costs and enhancing durability. Manufacturers provide tailored solutions that meet specific construction requirements, ensuring optimal performance.

- How Does EPS Resin Compare to Other Insulation Materials?

EPS resin stands out among insulation materials due to its low density and high R-value, which measures thermal resistance. It is lighter and easier to handle than alternatives like fiberglass or mineral wool. EPS resin’s moisture and chemical resistance further enhance its suitability for various insulation applications, offering a longer lifespan and better performance.

- The Versatility of EPS Resin in Packaging Solutions

EPS resin is a preferred choice in the packaging industry due to its lightweight and cushioning properties. Electronics, perishables, and fragile items benefit from the protection EPS resin provides against shocks and vibrations. Its thermal insulation also ensures temperature-sensitive products remain intact during transit, making it indispensable for cold chain logistics.

- Customizing EPS Resin for Specific Industrial Applications

Many EPS resin manufacturers offer customization to meet unique industrial needs. Parameters such as bead size and expansion ratio can be adjusted to ensure the EPS resin fits specific applications. This flexibility makes EPS resin suitable for a vast array of uses, from packaging to construction and beyond.

- What Makes a Reliable EPS Resin Manufacturer?

A reliable EPS resin manufacturer combines technical expertise, advanced production facilities, and stringent quality control measures. Long-standing relationships with clients and a reputation for consistency and reliability are also indicative of a trustworthy manufacturer. Comprehensive after-sales support further underscores their commitment to customer satisfaction.

- The Role of EPS Resin in Sustainable Packaging

EPS resin plays a crucial role in sustainable packaging solutions. While it poses challenges due to its non-biodegradability, many manufacturers are implementing effective recycling programs. Innovative recycling techniques, such as thermal densification, significantly reduce EPS waste, repurposing it for other applications. This effort is critical in mitigating the environmental impact of EPS resin.

- EPS Resin: Innovations in Production Techniques

Innovations in EPS resin production techniques are driving the material’s evolution. Manufacturers are investing in automated systems that enhance precision and efficiency. Advances in chemical formulations are improving EPS resin’s properties, such as thermal insulation and impact resistance. These developments are broadening EPS resin’s application scope, making it even more versatile and valuable across various industries.

Image Description