EPS Raw Material Production Line Supplier | Dongshen

Product Main Parameters

| Parameter | Value |

|---|---|

| Production Capacity | 1-5 tons/day |

| Steam Consumption | 200-400 kg/ton |

| Water Consumption | 50-100 liters/ton |

| Power Requirement | 220V/380V, 50/60Hz |

| Operating Pressure | 0.6-0.8 MPa |

Common Product Specifications

| Specification | Value |

|---|---|

| Bead Size Range | 0.3-2.5 mm |

| Bead Density | 10-30 kg/m³ |

| Expansion Ratio | 20-50 times |

| Moisture Content | <1% |

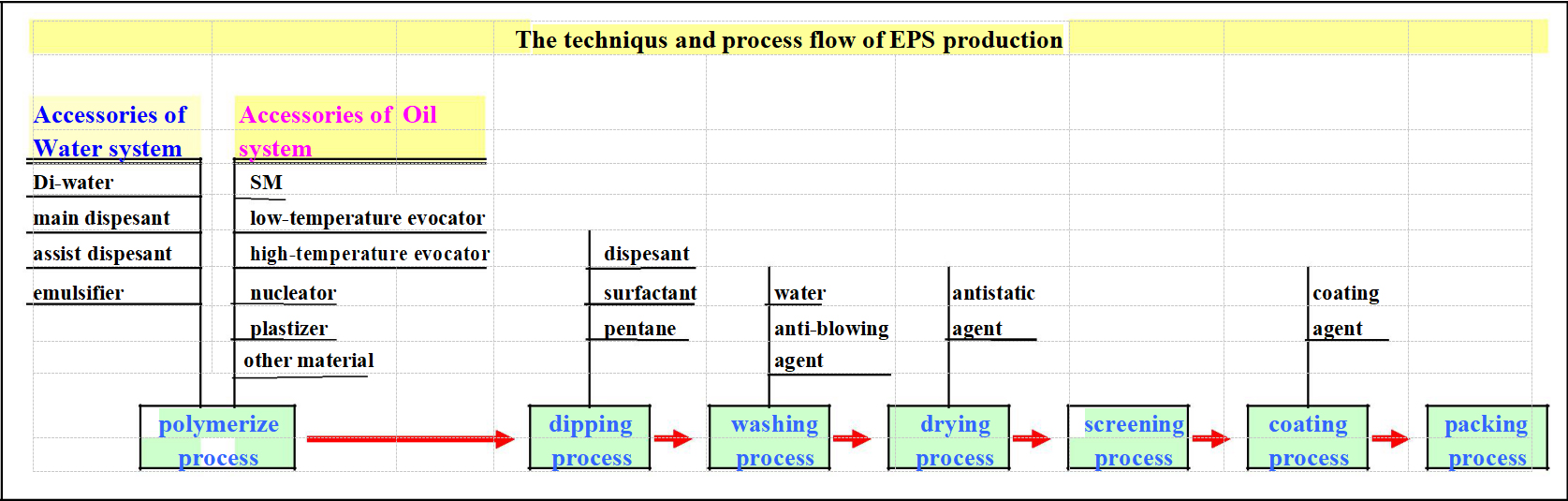

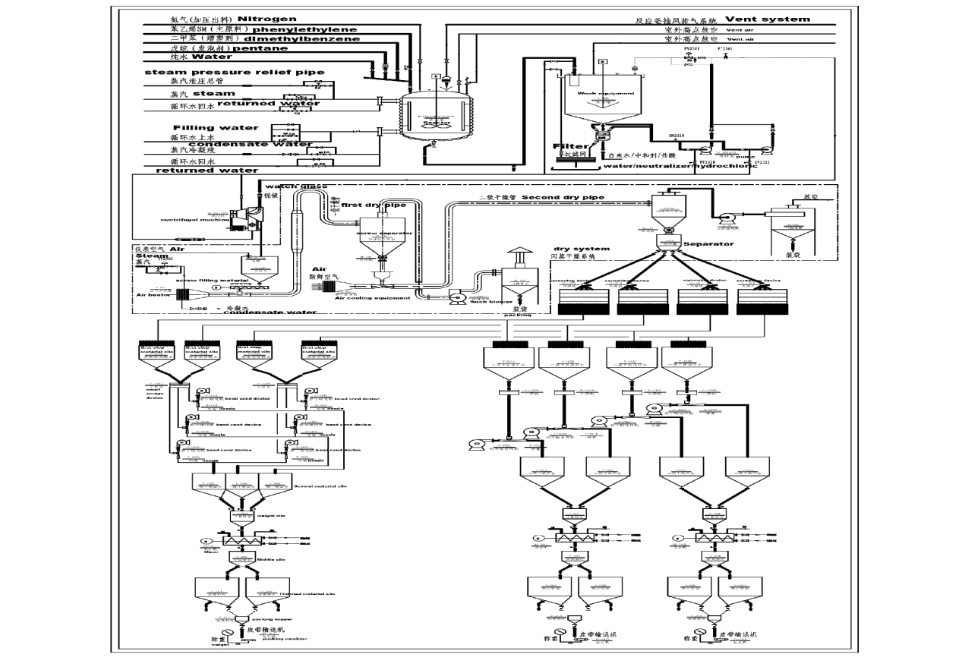

Product Manufacturing Process

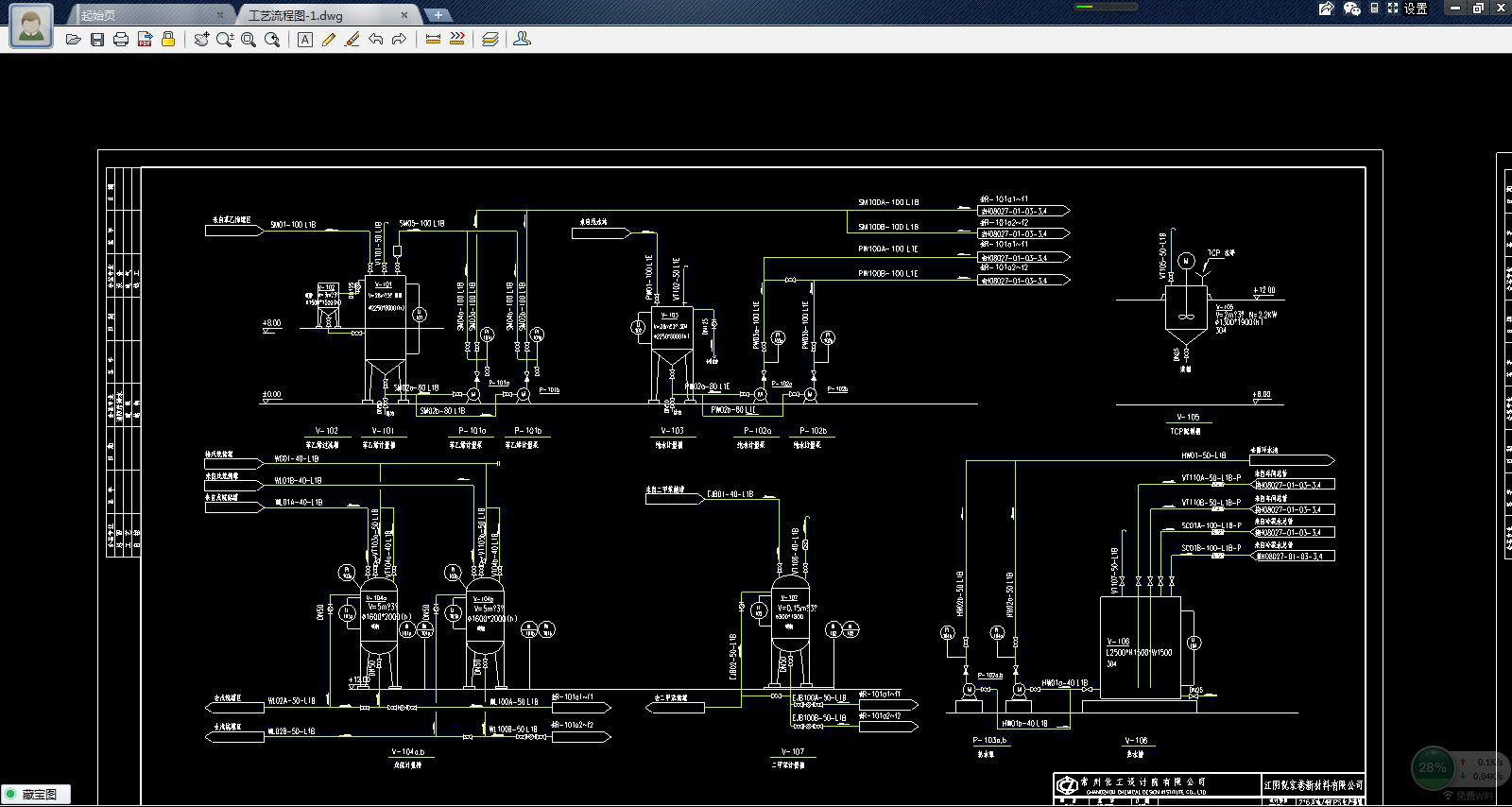

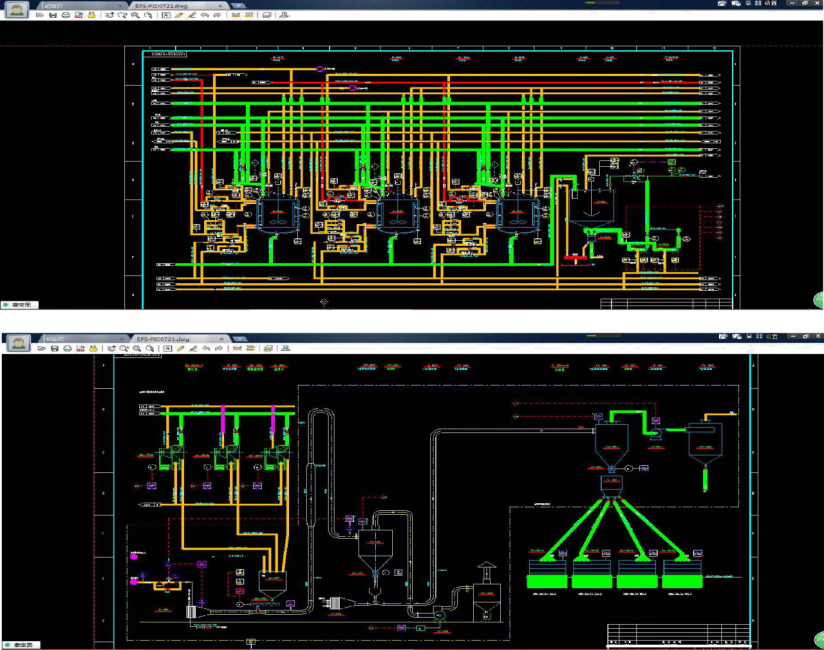

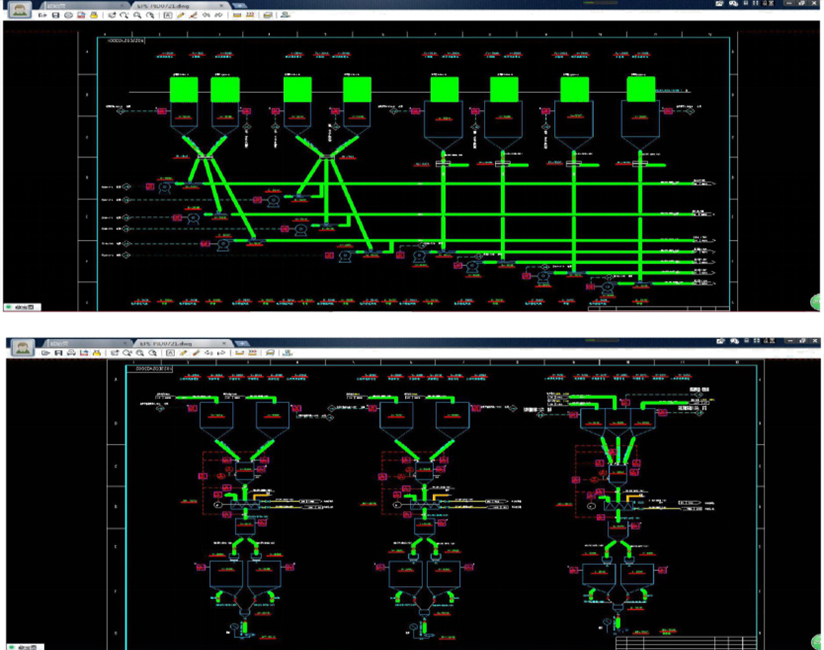

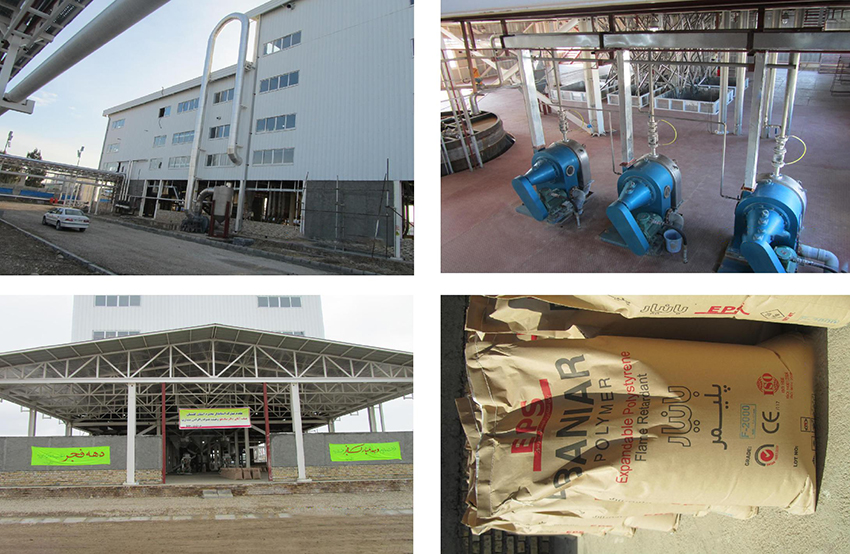

The EPS raw material production process involves several stages to transform polystyrene beads into expandable EPS beads. The process begins with polymerization and impregnation, where styrene monomer (SM) and a blowing agent are combined in a reactor. The mixture undergoes controlled heating and stirring to form polystyrene beads. These beads are then washed to remove impurities and dried using hot air to eliminate residual moisture. The final product is sorted and coated to enhance quality and performance. Advanced control systems ensure precise temperature and pressure management throughout the process, resulting in consistent and high-quality EPS beads.

Product Application Scenarios

EPS raw material production lines are used across various industries to create a wide range of EPS products. In the construction industry, EPS is utilized for thermal insulation in building walls, roofs, and foundations due to its excellent insulating properties and lightweight nature. In packaging, EPS protects fragile items during shipping with its cushioning and shock-absorbing capabilities. Common consumer goods made from EPS include disposable cups, food containers, and coolers. These versatile application scenarios highlight the demand for efficient and reliable EPS raw material production lines.

Product After-Sales Service

We offer comprehensive after-sales service including installation support, operator training, and technical assistance. Our team of experts is available for on-site maintenance, troubleshooting, and spare parts supply to ensure optimal performance and longevity of your EPS production line.

Product Transportation

Our EPS raw material production lines are securely packaged and transported using specialized freight services to ensure safe and timely delivery. We coordinate with reliable logistics partners to handle all aspects of transportation, from documentation to customs clearance, ensuring a smooth delivery process.

Product Advantages

- High production efficiency with automated control systems

- Customizable solutions to meet specific client needs

- Energy-efficient processes reducing operational costs

- Advanced recycling capabilities minimizing waste

- Comprehensive after-sales support ensuring long-term reliability

Product FAQ

- Q: What is the production capacity of the EPS raw material production line?

A: Our EPS raw material production lines have a production capacity ranging from 1 to 5 tons per day, depending on the specific requirements of the client. - Q: Can the EPS production line be customized?

A: Yes, we offer customizable solutions to meet the specific needs of our clients, including adjustments in capacity, bead size, and other parameters. - Q: What kind of control systems are used in the EPS production line?

A: We use advanced DCS (Distributed Control Systems) for precise control of temperature, pressure, and other critical parameters throughout the production process. - Q: How is the quality of the EPS beads ensured?

A: Quality is ensured through stringent control of production parameters, frequent sampling and testing, and the use of high-quality raw materials and additives. - Q: What after-sales services are provided?

A: We offer a range of after-sales services including installation support, operator training, technical assistance, on-site maintenance, and spare parts supply. - Q: How long does it take to complete the installation of the EPS production line?

A: The installation time varies depending on the complexity of the system, but typically ranges from a few weeks to a couple of months. - Q: What are the environmental considerations for the EPS production line?

A: Our production lines are designed with energy-efficient processes and recycling capabilities to minimize environmental impact. We also offer biodegradable alternatives to traditional EPS. - Q: Can the EPS production line handle different types of raw materials?

A: Yes, our production lines can process various grades of polystyrene beads and are adaptable to different formulations and additives. - Q: What kind of training is provided for operators?

A: We provide comprehensive training for operators covering all aspects of the production process, equipment operation, maintenance, and safety protocols. - Q: How is the transportation of the EPS production line managed?

A: We coordinate with reliable logistics partners to ensure safe and timely transportation of the production line, handling all necessary documentation and customs clearance.

Product Hot Topics

- Innovations in EPS Raw Material Production Lines

The latest innovations in EPS raw material production lines focus on enhancing efficiency and sustainability. Advanced automation and control systems ensure consistent product quality while optimizing energy consumption. Recycling capabilities are integrated to minimize waste and environmental impact. These technological advancements are crucial for meeting the growing demand for high-quality EPS products in various industries. As a leading supplier, Dongshen continuously invests in research and development to stay at the forefront of these innovations. - Energy Efficiency in EPS Production

Energy efficiency is a key consideration in the design of EPS raw material production lines. Modern systems utilize efficient steam generation and recovery technologies, which significantly reduce energy consumption and operational costs. Additionally, automated monitoring and control systems help in optimizing energy use throughout the production process. These energy-efficient practices not only lower costs but also contribute to environmental sustainability, making them a vital aspect of contemporary EPS production lines. - Sustainability in EPS Production

While EPS is a highly functional material, its environmental impact has been a concern. However, advancements in recycling and the development of biodegradable alternatives are addressing these issues. Sustainable practices in EPS production include using renewable energy sources, improving recycling systems, and developing eco-friendly materials. As a responsible supplier, Dongshen is committed to implementing these sustainable practices in its production lines to minimize environmental impact. - Applications of EPS in Construction

EPS is widely used in the construction industry for its excellent thermal insulation properties and lightweight nature. It is utilized in building walls, roofs, and foundations to enhance energy efficiency and reduce heating and cooling costs. EPS insulation boards are also easy to install and provide long-term durability. These advantages make EPS a preferred choice for modern construction projects, highlighting the importance of efficient production lines to meet industry demands. - EPS in Packaging Solutions

EPS is an ideal material for packaging due to its cushioning properties and shock absorption capabilities. It protects fragile items during shipping and handling, ensuring they reach their destination in perfect condition. EPS packaging is also lightweight, which helps in reducing transportation costs. The versatility and reliability of EPS packaging make it a popular choice across various industries, from electronics to food and beverages. - Future Trends in EPS Production

The future of EPS production is shaped by continuous technological innovations and a growing emphasis on sustainability. Advances in automation, energy efficiency, and recycling are driving the development of more efficient and eco-friendly production lines. The demand for high-quality EPS products in diverse applications is expected to grow, making it essential for suppliers like Dongshen to stay at the forefront of these trends and offer state-of-the-art production solutions. - Quality Control in EPS Production

Quality control is critical in EPS production to ensure consistent and high-quality products. Advanced control systems monitor and adjust production parameters in real-time, ensuring optimal conditions for bead formation and expansion. Frequent sampling and testing are conducted to check the quality of EPS beads at various stages of production. By maintaining strict quality control measures, suppliers can deliver reliable and superior EPS products to their clients. - Customizing EPS Production Lines

One of the key advantages of working with a specialized supplier like Dongshen is the ability to customize EPS production lines to meet specific client requirements. From adjusting production capacity to tailoring bead sizes and formulations, customization ensures that the production line aligns perfectly with the client's needs. This flexibility is crucial for addressing unique challenges and maximizing the efficiency and effectiveness of the production process. - EPS Production Line Installation and Training

Successful installation and operation of an EPS production line require expert support and training. Dongshen provides comprehensive installation services, ensuring that the production line is set up correctly and efficiently. Additionally, operator training covers all aspects of production, maintenance, and safety, equipping the client's team with the knowledge and skills needed to run the production line smoothly. This holistic approach ensures long-term reliability and optimal performance. - Environmental Impact of EPS and Mitigation Strategies

The environmental impact of EPS has been a topic of concern, primarily due to its non-biodegradable nature. However, strategies to mitigate this impact are being actively developed and implemented. These include enhancing recycling capabilities, promoting the use of biodegradable alternatives, and adopting sustainable production practices. As an industry leader, Dongshen is committed to reducing the environmental footprint of its EPS production lines through continuous innovation and adherence to eco-friendly standards.

Image Description