Eps Mold - Dongshen

Hangzhou Dongshen Machinery Engineering Co., Ltd is a dedicated and reputable manufacturer of EPS machines, EPS moulds, and spare parts, prominently known as Dongshen EPS Machine. Renowned for exporting EPS molds globally, Dongshen EPS Machine provides a comprehensive range of products, including EPS Preexpanders, EPS Shape Molding Machines, EPS Block Molding Machines, and CNC Cutting Machines. Our core competencies lie in our robust technical team which assists clients in designing new EPS factories and delivering turnkey EPS projects. We also aid established EPS factories in enhancing their production capabilities by reducing energy consumption and elevating production capacity.

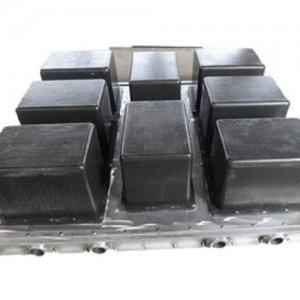

Dongshen EPS Machine specializes in the manufacture of high-quality EPS moulds. Our aluminum EPS moulds are crafted from top-tier aluminum material, with mould frames constructed from extruded aluminum alloy profiles, ensuring durability and longevity. We cater to a diverse clientele, customizing EPS moulds for various brands of EPS machines from countries such as Germany, Korea, Japan, and Jordan.

Moreover, our expertise extends to the production of EPS raw material equipment. We provide a complete solution for EPS beads production, offering equipment like EPS reactors, washing tanks, and sieving machines, tailored to client capacity requirements. Our clients entrust us as their sourcing partner, owing to our honesty and reliability. As industry-leading EPS molders, Dongshen EPS Machine is committed to delivering top-quality products and impeccable service to our global clientele.

Dongshen EPS Machine specializes in the manufacture of high-quality EPS moulds. Our aluminum EPS moulds are crafted from top-tier aluminum material, with mould frames constructed from extruded aluminum alloy profiles, ensuring durability and longevity. We cater to a diverse clientele, customizing EPS moulds for various brands of EPS machines from countries such as Germany, Korea, Japan, and Jordan.

Moreover, our expertise extends to the production of EPS raw material equipment. We provide a complete solution for EPS beads production, offering equipment like EPS reactors, washing tanks, and sieving machines, tailored to client capacity requirements. Our clients entrust us as their sourcing partner, owing to our honesty and reliability. As industry-leading EPS molders, Dongshen EPS Machine is committed to delivering top-quality products and impeccable service to our global clientele.

EPS MOULD

EPS MOULD FAQ

What is EPS mold?▾

Expanded Polystyrene (EPS) mold is a crucial element in the manufacturing of a wide range of lightweight, durable, and versatile products. At its core, EPS mold refers to the tools and processes used to shape and form expanded polystyrene foam, a material known for its excellent insulation properties, structural integrity, and cost-effectiveness. EPS molds are utilized across various industries, from construction to packaging, due to their ability to produce precise and consistent components efficiently.

EPS molding starts with the creation of the mold itself, which is typically made from aluminum or other durable materials to ensure longevity and consistency in production. The design of the mold is highly customizable, allowing manufacturers to create intricate shapes and structures as needed. This flexibility is one of the key advantages of EPS over other materials. Once the mold is ready, polystyrene beads are expanded and fused within it under controlled steam and pressure. The result is a single, cohesive block of foam shaped perfectly to the mold's specifications.

EPS molds are used in a diverse array of applications. In the construction industry, for instance, they are essential in creating insulation panels, decorative architectural elements, and even lightweight concrete forms. The material's insulating properties make it ideal for energy-efficient building designs. In packaging, EPS molds are vital for producing custom-fit packaging solutions that protect delicate items during transit. The automotive and electronics sectors also benefit from EPS molds, using them to manufacture components that require precise dimensions and impact resistance.

The advantages of using EPS molds are numerous. One of the primary benefits is the material's lightweight nature, which reduces transportation costs and makes handling easier. Additionally, EPS is highly durable and provides excellent thermal insulation, making it ideal for a variety of uses. The customization potential of EPS molds allows for the creation of complex shapes and sizes, meeting specific client requirements without incurring high costs. Moreover, the production process is relatively quick and efficient, enabling high-volume production with consistent quality.

While EPS is often criticized for its environmental impact, advancements in recycling and material recovery have mitigated many of these concerns. EPS molders today are increasingly adopting sustainable practices, such as recycling used foam back into the production process and exploring biodegradable alternatives. These efforts not only reduce the environmental footprint but also make EPS a more sustainable choice for modern manufacturing needs.

Eps Molders play a pivotal role in the entire EPS molding process. These companies are responsible for the design, fabrication, and maintenance of the molds, ensuring they meet exact specifications and produce high-quality end products. With a focus on innovation and efficiency, Eps Molders continually improve their processes, incorporating the latest technologies to enhance production capabilities and reduce costs. Their expertise is essential for industries that rely on EPS products, providing the necessary technical support and customization options to meet diverse market demands.

In summary, EPS molds are an indispensable tool in the manufacturing sector, offering a blend of versatility, efficiency, and cost-effectiveness. Through the expertise of Eps Molders, industries can leverage the benefits of expanded polystyrene to create high-quality, sustainable products tailored to their specific needs. As advancements continue in technology and sustainability, the role of EPS molds is poised to become even more significant in driving innovation across various fields.

● The Fundamentals of EPS Mold

EPS molding starts with the creation of the mold itself, which is typically made from aluminum or other durable materials to ensure longevity and consistency in production. The design of the mold is highly customizable, allowing manufacturers to create intricate shapes and structures as needed. This flexibility is one of the key advantages of EPS over other materials. Once the mold is ready, polystyrene beads are expanded and fused within it under controlled steam and pressure. The result is a single, cohesive block of foam shaped perfectly to the mold's specifications.

● Applications of EPS Molding

EPS molds are used in a diverse array of applications. In the construction industry, for instance, they are essential in creating insulation panels, decorative architectural elements, and even lightweight concrete forms. The material's insulating properties make it ideal for energy-efficient building designs. In packaging, EPS molds are vital for producing custom-fit packaging solutions that protect delicate items during transit. The automotive and electronics sectors also benefit from EPS molds, using them to manufacture components that require precise dimensions and impact resistance.

● Advantages of Using EPS Mold

The advantages of using EPS molds are numerous. One of the primary benefits is the material's lightweight nature, which reduces transportation costs and makes handling easier. Additionally, EPS is highly durable and provides excellent thermal insulation, making it ideal for a variety of uses. The customization potential of EPS molds allows for the creation of complex shapes and sizes, meeting specific client requirements without incurring high costs. Moreover, the production process is relatively quick and efficient, enabling high-volume production with consistent quality.

● Environmental Considerations

While EPS is often criticized for its environmental impact, advancements in recycling and material recovery have mitigated many of these concerns. EPS molders today are increasingly adopting sustainable practices, such as recycling used foam back into the production process and exploring biodegradable alternatives. These efforts not only reduce the environmental footprint but also make EPS a more sustainable choice for modern manufacturing needs.

● The Role of Eps Molders

Eps Molders play a pivotal role in the entire EPS molding process. These companies are responsible for the design, fabrication, and maintenance of the molds, ensuring they meet exact specifications and produce high-quality end products. With a focus on innovation and efficiency, Eps Molders continually improve their processes, incorporating the latest technologies to enhance production capabilities and reduce costs. Their expertise is essential for industries that rely on EPS products, providing the necessary technical support and customization options to meet diverse market demands.

In summary, EPS molds are an indispensable tool in the manufacturing sector, offering a blend of versatility, efficiency, and cost-effectiveness. Through the expertise of Eps Molders, industries can leverage the benefits of expanded polystyrene to create high-quality, sustainable products tailored to their specific needs. As advancements continue in technology and sustainability, the role of EPS molds is poised to become even more significant in driving innovation across various fields.