EPS Molders Wholesale: Filling Gun for Shape Molding Machine

Product Main Parameters

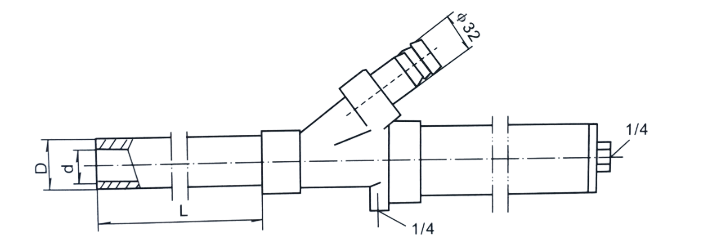

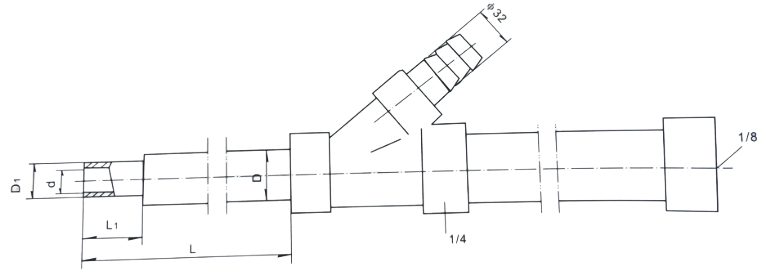

| Type | Diameter (mm) | Length (mm) | Material |

|---|---|---|---|

| Common Type | 22-220 | 150, 180 | Stainless Steel |

| Air Front Small Head | 30-50 | 150, 180 | Stainless Steel |

| German Type | 50 | 310 | Stainless Steel, Copper |

Common Product Specifications

| Model | Diameter (mm) | Length (mm) |

|---|---|---|

| AFSH-30-150 | 30 | 150 |

| AFSH-30-180 | 30 | 180 |

| CT-220-150 | 220 | 150 |

Product Manufacturing Process

EPS Molders filling guns are crafted through a series of precise manufacturing steps that ensure their reliability and efficiency. The process begins with selecting high-grade stainless steel or copper, which is then cut and shaped into barrels and components. Advanced CNC machining is used to achieve the exact specifications required for different types of filling guns. Each piece is then meticulously assembled and tested under various conditions to ensure consistent performance and durability. The final product is coated for corrosion resistance, enhancing its lifespan and effectiveness in challenging environments.

Product Application Scenarios

EPS Molders filling guns are vital in sectors where precision and efficiency in molding are paramount. In the packaging industry, they aid in forming protective casing for electronics and food items, ensuring insulation and shock resistance. In construction, these guns are instrumental in creating insulation panels that enhance energy efficiency in buildings. Automotive industries utilize EPS filling guns to develop lightweight components that improve vehicle fuel efficiency and safety. Their versatility and adaptability make them suitable for diverse consumer goods, including sports equipment and protective gear.

Product After-Sales Service

- One-year warranty on all manufacturing defects

- 24/7 customer support with dedicated technical assistance

- Free replacement parts during the warranty period

Product Transportation

- Secure packaging ensures safe delivery worldwide

- Flexible shipping options to meet urgent supply needs

- Tracking services available for real-time shipment updates

Product Advantages

- Cost-effective wholesale pricing for EPS Molders

- Adaptable to various industry-specific requirements

- Excellent durability and precision in molding applications

Product FAQ

- What materials are used in the EPS filling guns?

EPS filling guns are crafted primarily from high-quality stainless steel, with options for copper barrels available, ensuring durability and corrosion resistance for long-term use. - How do I choose the right filling gun for my needs?

Consider your industry-specific requirements, such as desired diameter and length. Our technical team can assist in selecting the perfect model to enhance your production efficiency. - Are custom sizes available?

Yes, we offer customization to meet specific dimensions and specifications, ensuring optimal performance for your particular application scenario. - What is the warranty period for the filling guns?

We provide a comprehensive one-year warranty covering manufacturing defects, with customer support available for any assistance needed. - Can these guns be used for both block and shape molding?

Yes, our filling guns are versatile and can be used for both EPS block and shape molding machines, catering to diverse manufacturing needs. - What payment options are available?

We accept various payment methods for your convenience, including bank transfers, credit cards, and international payment gateways. - Is technical support available post-purchase?

Our dedicated technical team is available to provide after-sales support, ensuring your equipment operates efficiently and addressing any queries you may have. - What is the estimated delivery time?

Delivery times vary based on location and order size. We prioritize prompt shipping and offer tracking services for real-time updates. - How do I maintain the filling gun?

Regular cleaning and inspection are recommended to ensure optimal performance and longevity. Follow our maintenance guide provided with each purchase. - Are there eco-friendly options available?

While EPS is not biodegradable, we are committed to sustainability efforts including offering recyclable materials and supporting recycling programs.

Product Hot Topics

- EPS Molders: Revolutionizing Packaging Solutions

The introduction of advanced EPS Molders filling guns has transformed the packaging industry by offering lightweight, durable solutions with superior insulating properties. Companies now rely on these efficient tools to ensure their products are transported safely, showcasing the technology's crucial role in modern logistics. - Enhancing Construction Efficiency with EPS Molders

EPS Molders filling guns have made significant impacts in the construction sector, particularly in the development of insulation panels. These panels are key to reducing energy consumption and improving building sustainability, highlighting EPS's importance in eco-friendly construction methods. - Automotive Lightweighting and EPS Molders

In the automotive industry, EPS Molders filling guns contribute to creating lightweight, fuel-efficient components such as bumpers and seating systems. This shift towards lighter materials not only promotes sustainability but also enhances vehicle safety, showcasing EPS's multifaceted benefits. - Cost-Effective Solutions for Consumer Goods

EPS Molders, through their innovative filling guns, are providing cost-effective solutions for the creation of diverse consumer goods like coolers and toys. Their adaptability and affordability offer businesses an edge in producing competitive products in the market. - Overcoming Environmental Challenges with EPS Molders

Despite environmental concerns, EPS Molders are implementing new recycling techniques and biodegradable alternatives, paving the way for a greener future. This development is crucial in mitigating the ecological impact of EPS products globally. - Customizable Solutions in EPS Molding

EPS Molders filling guns stand out for their customizable nature, allowing businesses to order specific sizes and specifications. This flexibility ensures that every client receives a product perfectly suited to their unique industry demands. - The Future of EPS Molding Technology

As technology advances, EPS Molders are at the forefront of innovation, exploring sustainable alternatives and efficiency improvements. These efforts promise a future where EPS products are both high-performing and environmentally friendly. - EPS Recycling Initiatives: A Step Towards Sustainability

Embracing recycling programs, EPS Molders are actively contributing to environmental conservation efforts. By reprocessing used EPS into new products, they're reducing waste and promoting a circular economy. - Global Impact of EPS Molders in Industrial Applications

EPS Molders filling guns have a global reach, impacting numerous industries with their efficient molding capabilities. Their role in enhancing production systems worldwide underscores their significance in contemporary manufacturing. - Fine-Tuning Manufacturing Processes with EPS Molders

Precision and efficiency define the use of EPS Molders filling guns in modern manufacturing. By optimizing these processes, businesses achieve higher quality standards and increased production capacities, driving industry success.

Image Description