EPS Machine Manufacturer: Automatic Cutting Line

Product Main Parameters

| Parameter | Details |

|---|---|

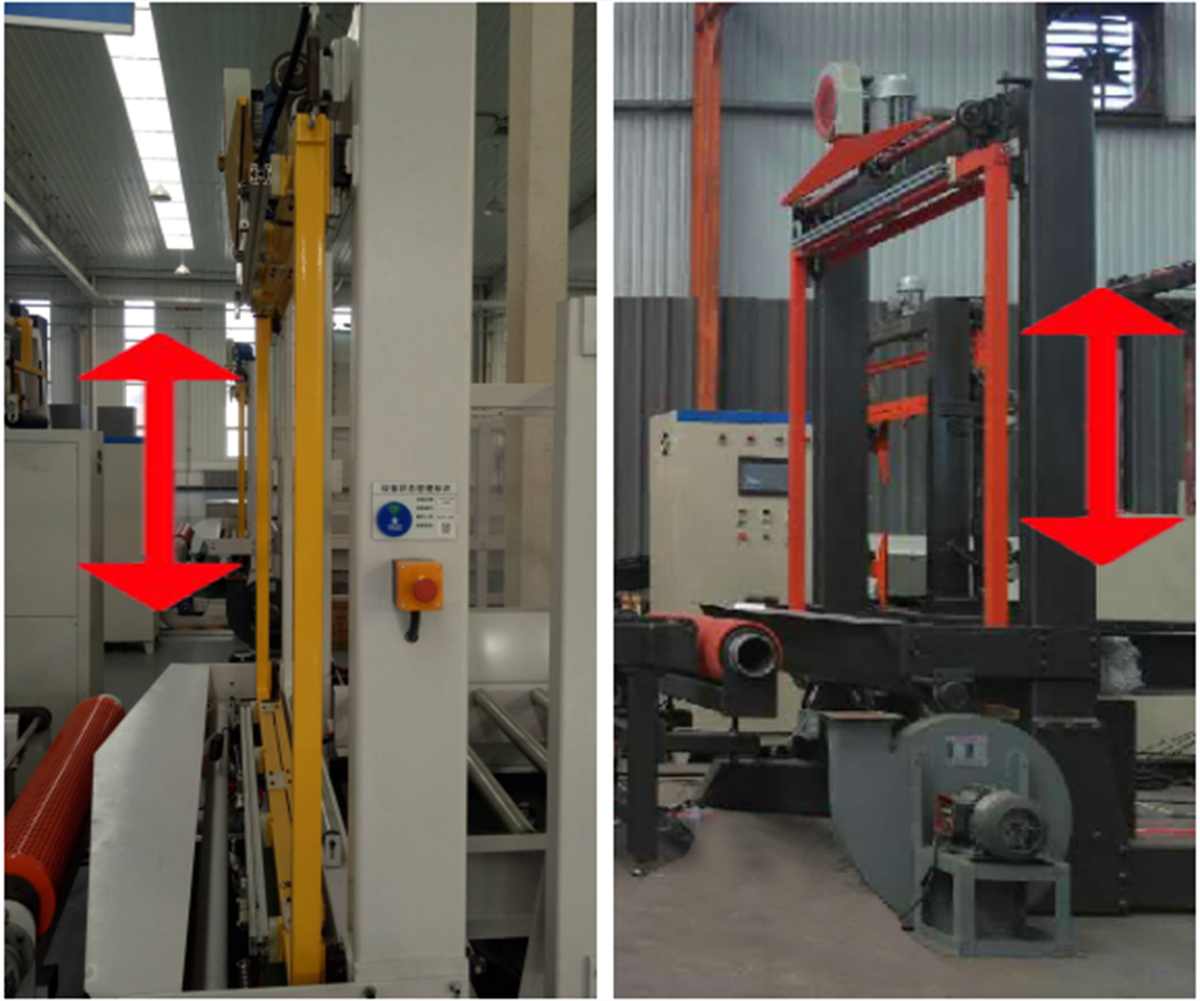

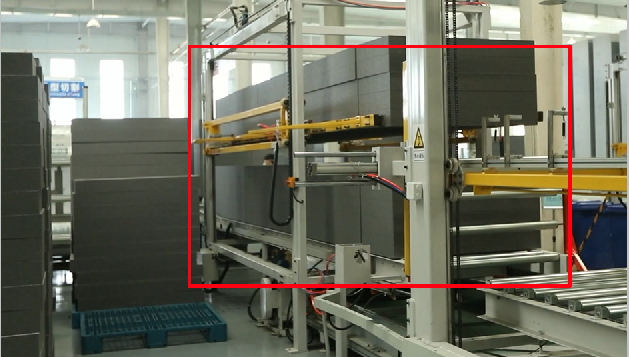

| Horizontal Cut Precision | Automatic Wire Setting, Oscillation Cut |

| Vertical Cut | Oscillation Cut with Down Scrape Removal |

| Cross Cut | Automatic Block Alignment, Fast Wire Changing |

| Control System | Touch Screen, PLC by DELTA |

Common Product Specifications

| Specification | Details |

|---|---|

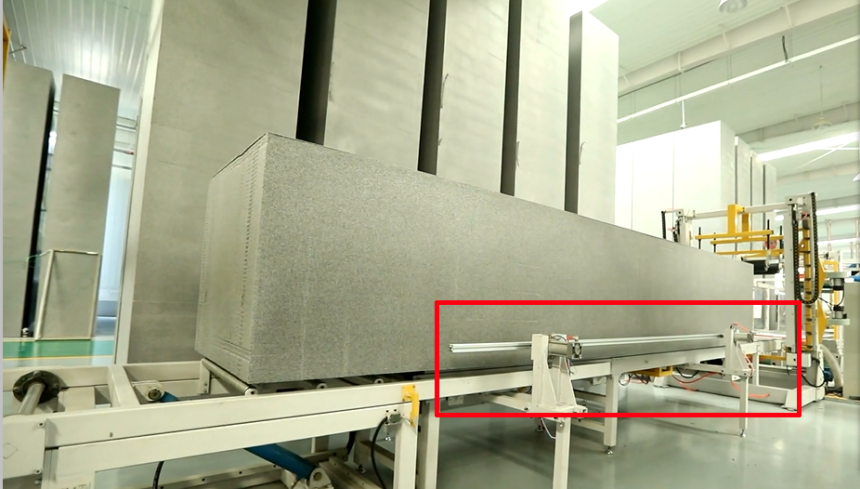

| Block Height | 1260mm (Horizontal), 1200-1220mm (Vertical) |

| Transformer Specifications | 15KW for Horizontal, 3KW for Vertical, 5KW for Cross |

Product Manufacturing Process

The manufacturing of EPS involves pre-expanding polystyrene beads, which are then molded into blocks using heat and pressure. Advanced machinery, including pre-expanders and molding machines, are utilized to enhance the structural integrity and precision of the EPS products. Automation in cutting and molding has significantly improved production efficiency, reducing manual labor and increasing output. Leading manufacturers focus on sustainable practices and energy efficiency to minimize environmental impact, adhering to stringent regulatory standards. The final products undergo rigorous quality checks to ensure they meet industrial requirements.

Product Application Scenarios

EPS machines are employed in numerous industries due to their versatile applications. In packaging, EPS provides lightweight, protective solutions for fragile goods. The construction segment utilizes EPS for its thermal insulation properties, critical in developing energy-efficient buildings. EPS is also pivotal in producing impact protection gear such as helmets and vehicle bumpers. Manufacturers are increasingly adapting EPS technology to create customized solutions that meet specific client needs, enabling widespread adoption in various sectors.

Product After-Sales Service

- 24/7 Customer Support

- Comprehensive Warranty Packages

- On-Site Maintenance and Repair

Product Transportation

- Secure Packaging for Safe Transit

- Reliable International Shipping Options

- Customs and Documentation Assistance

Product Advantages

- High Precision and Efficiency

- Customizable for Diverse Applications

- Sustainable and Energy-Efficient Production

Product FAQ

- What is the lifespan of an EPS cutting line?

An EPS cutting line, manufactured by a leading EPS machine manufacturer, typically has a lifespan of 10-15 years with proper maintenance.

- Can the cutting line handle custom block sizes?

Yes, our EPS machine manufacturer designs lines to be adaptable, accommodating various block sizes and specifications.

- How does the cutting line improve production efficiency?

The automatic alignment and fast wire changing system of the cutting line significantly reduce downtime, maximizing output.

- Is the machine compatible with international standards?

As a reputable EPS machine manufacturer, our equipment adheres to all major international standards, ensuring compliance and safety.

Product Hot Topics

- Impact of Technological Advancements on EPS Manufacturing

Innovations in EPS machine manufacturing have revolutionized production processes, enabling higher precision and efficiency. Automation plays a crucial role, reducing human intervention and minimizing errors.

- Sustainability Initiatives in EPS Production

EPS manufacturers are increasingly embracing sustainable practices, investing in recycling and waste reduction technologies to lower environmental impacts.

- Customization Trends in the EPS Industry

Demand for custom EPS solutions is on the rise, with manufacturers developing adaptable machines to meet diverse client requirements.

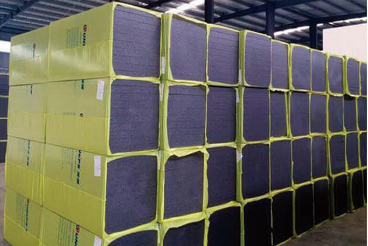

Image Description