Dongshen’s High-Efficiency Polystyrene Machine: The Ultimate EPS Block Cutting Solution

Features

Full automatic, big capacity, durable and save labor cost

A.Horizontal cut

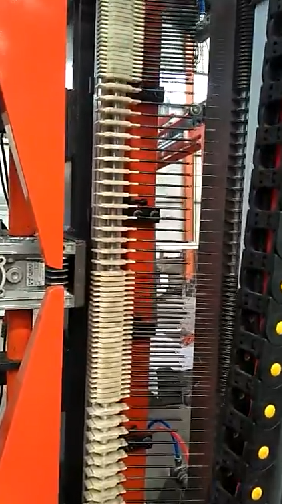

1、High precision Automatic Wire setting (upgrade type) & Oscillation cut

2、Suitable for block height 1260mm, equip with block tilter & press roller

3、15KW transformer & isobaric regulator for cutting wires.

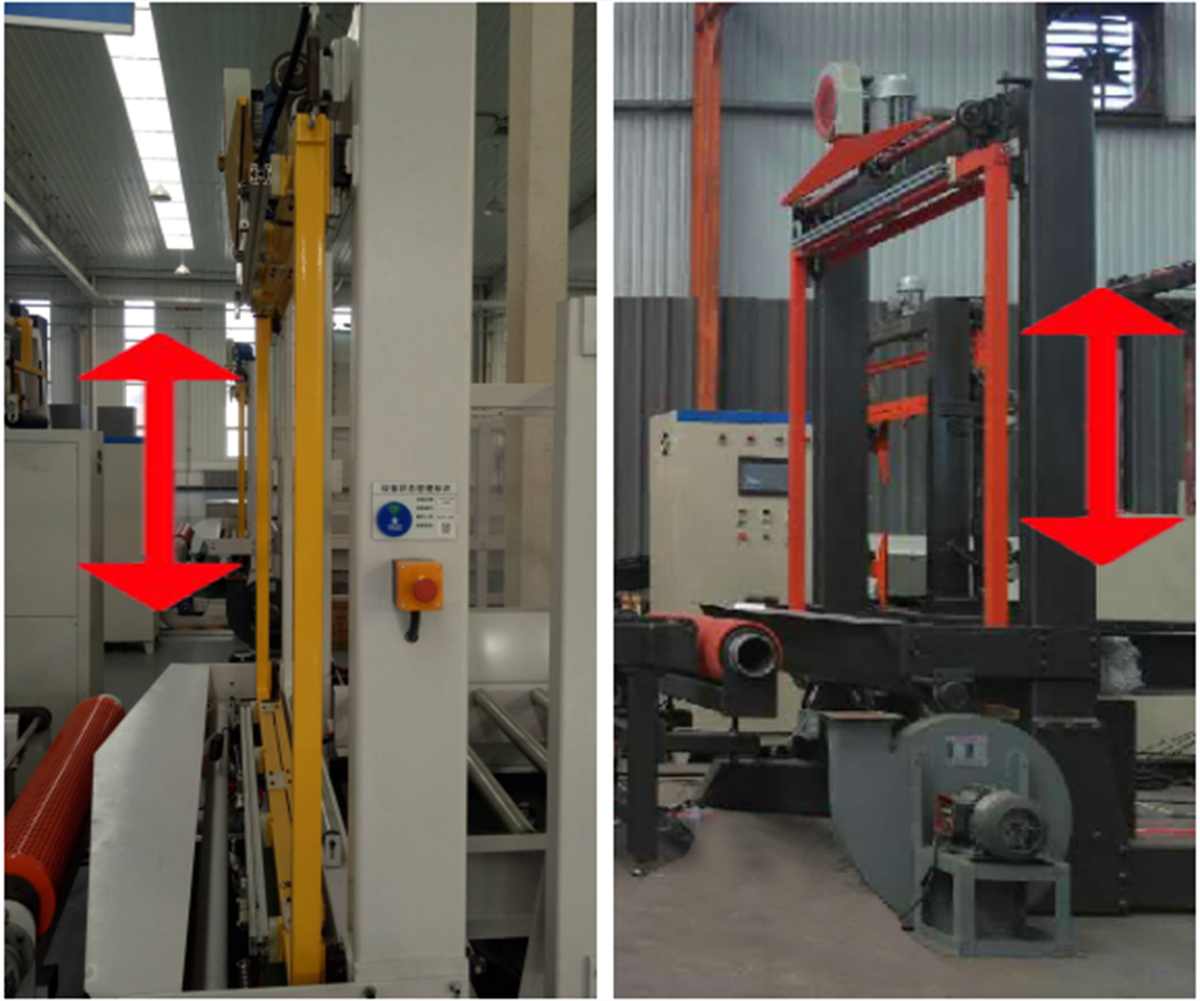

B. Vertical cut

Oscillation cut with down scrape removal part, suitable for block1200~ 1220mm.

2、In future, four side scrape crushed can be installed (optional)

3、3Kw transformer & isobaric regulator for cutting wires.

B.Cross cut

1、Scrape crusher can be installed in future(optional.)

2、5Kw Transformer & isobaric regulator for cutting wire

3、Automatic block alignment system;

4、Fast wire changing system.

5. Packing Machine can be installed in Future(optional)

6. Safety cover for all chains.

D. Control system:

1、Touch screen, PLC and transducer brand: DELTA from Taiwan

2、Pneumatic parts brand: AIRTEC from Taiwan

3、Korean AUTONICS or American BANNER photo sensor & Japan OMRON U Sensor

4、Electronic components SCHNEIDER;Transformer: China CHNT

5. Roller brand: Demon (China Top brand)

6、Liner track brand PMI from Taiwan

7、Servo motor & driver brand DELTA from Taiwan with perfect performance.

Optional Function:

1, Block storage line & protective fence

Made of steel tube and rollers, 5 or 6 blocks can be stocked here and ready for cut.

2, Hydraulic block tilter

Enable EPS block from vertical to horizontal, hydraulic operation, safe and steady

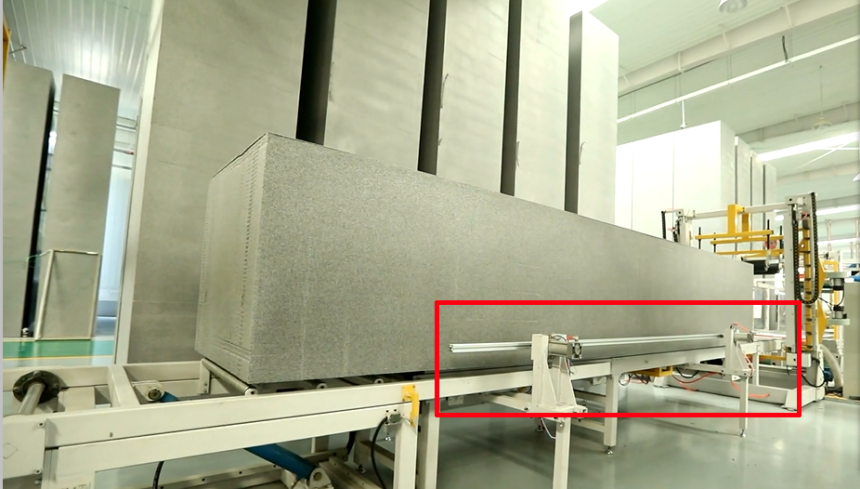

3, Automatic Alignment system in horizontal

It keeps EPS block in machine middle position, to get best cutting precision >

4, Scrape recycle system

Scrape collection belt, it collects all scrape on this transportation belt.

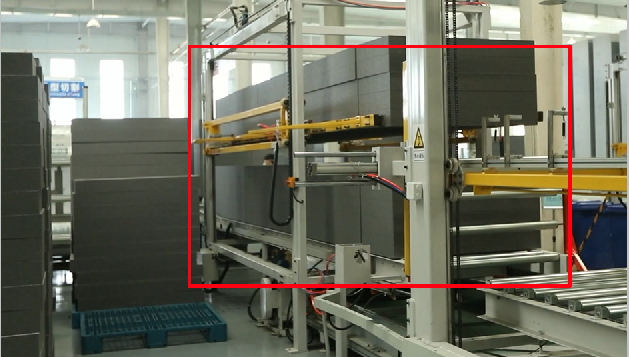

5, De-stacker

The de-stacker would lift the top half block (600mm height) , and bottom half block would go to packing machine for packing first.

When it is finished, the top half will come down for packing.

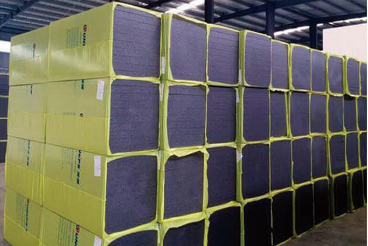

6, Film packing machine

This is the final step of cutting. After that the blocks are packed by film and ready for sell.

Related video

A factor that sets Dongshen's Polystyrene Machine apart from the rest is its ability to combine these top-grade features while maintaining the highest quality standards. It proves to be a wise investment, benefitting from its technological sophistication and providing an unbeaten level of ease and efficiency. In conclusion, the Polystyrene Machine from Dongshen is a leap forward in EPS block cutting technology. It represents a perfect amalgamation of automation, capacity, and durability, strongly capable of saving labor cost and increasing productivity in the long run. Avail yourself of this groundbreaking machine, and let Dongshen take care of your EPS block cutting needs professionally, economically, and efficiently.