Discover Dongshen's Revolutionary Styrofoam Granulator for EPS Foam Block Production

Product Details

Expanded polystyrene foam block making machine is used to make EPS blocks, then cut to sheets for house insulation or packing. Popular products made from EPS sheets are EPS sandwich panels, 3D panels, inner and outer wall insulation panels, glass packing, furniture packing etc.

Expanded polystyrene foam block making machine is suitable for small capacity request and low density blocks production, it’s economic EPS machine. With special technology, our expanded polystyrene foam block making machine can make 4g/l density blocks, block is straight and of good quality.

Machine completes with main body, control box, blower, weighing system etc.

Main Features

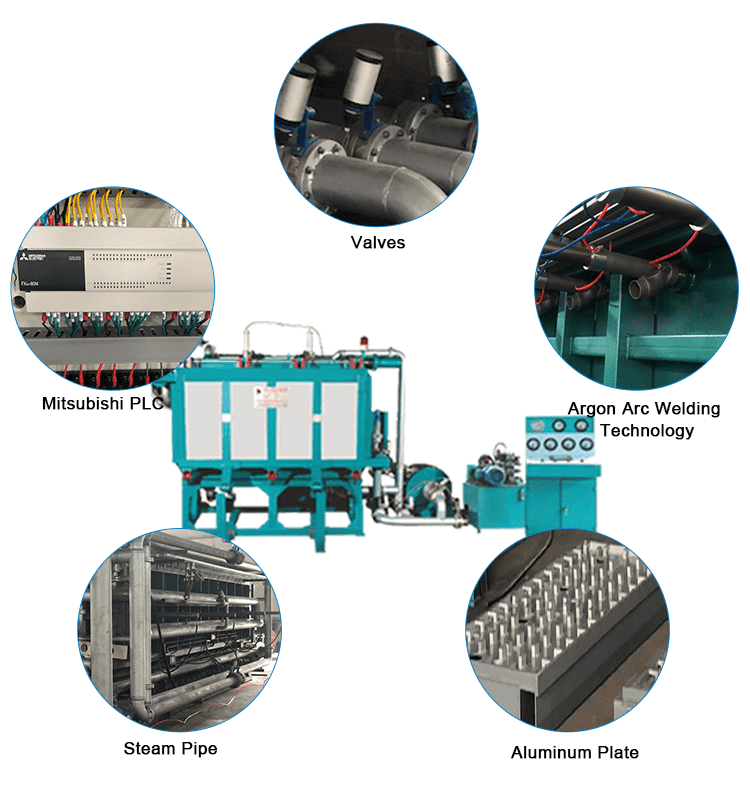

1. The machine adopts Mitsubishi PLC and Winview touch screen for automatic mould opening, mould closing, material filling, steaming, temperature keeping, air cooling, demoulding and ejecting.

2. Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

3. Mould cavity is made of special aluminum alloy plate with high-efficiency heat conduction, aluminum plate thickness 5mm, with Teflon coating for easy demoulding.

4. The machine set up high-pressure blower for suction material. Cooling is done by convection air by blower.

5. Machine plates are from high-quality steel profile, through heat treatment, strong and no deformation.

6. Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

Main Technical Parameters

Item | Unit | PB2000A | PB3000A | PB4000A | PB6000A | |

Mould Cavity Size | mm | 2040*1240*630 | 3060*1240*630 | 4080*1240*630 | 6100*1240*630 | |

Block Size | mm | 2000*1200*600 | 3000*1200*600 | 4000*1200*600 | 6000*1200*600 | |

Steam | Entry | Inch | DN80 | DN80 | DN100 | DN150 |

| Consumption | Kg/cycle | 18~25 | 25~35 | 40~50 | 55~65 |

| Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

Compressed Air | Entry | Inch | DN40 | DN40 | DN50 | DN50 |

| Consumption | m³/cycle | 1~1.2 | 1.2~1.6 | 1.6~2 | 2~2.2 |

| Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

Drainage | Steam Vent | Inch | DN100 | DN150 | DN150 | DN150 |

Capacity 15kg/m³ | Min/cycle | 4 | 5 | 7 | 8 | |

Connect Load/Power | Kw | 6 | 8 | 9.5 | 9.5 | |

Overall Dimension (L*H*W) | mm | 3800*2000*2100 | 5100*2300*2100 | 6100*2300*2200 | 8200*2500*3100 | |

Weight | Kg | 3500 | 5000 | 6500 | 9000 | |

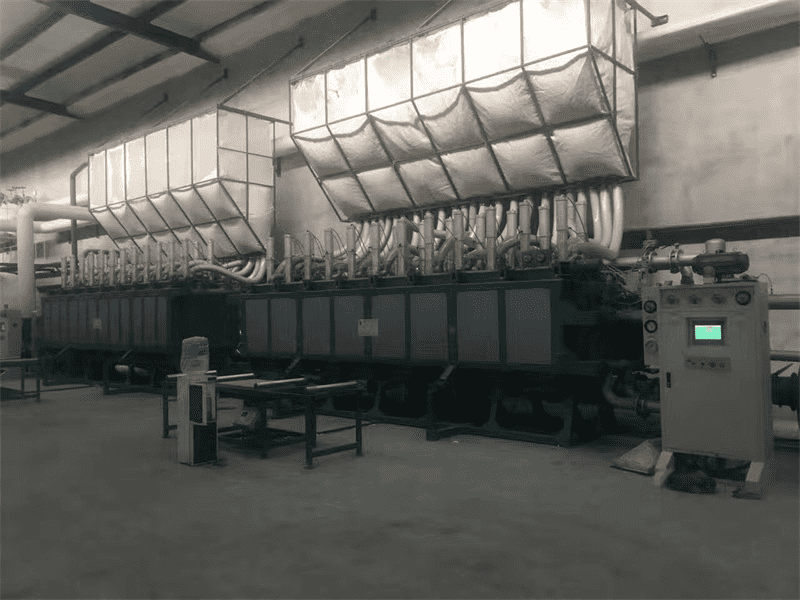

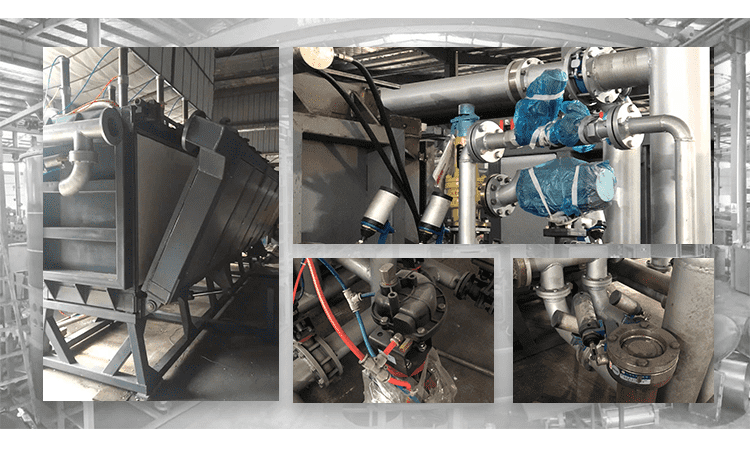

Case

Related video

Using the Styrofoam Granulator is an incredible way to keep production costs down while enhancing output quality. Its ease of operation and maintenance further adds to the productivity of the process, making it an indispensable tool for any industry relying on EPS foam blocks. In conclusion, Dongshen's Styrofoam Granulator is not only a game-changer in the production of EPS foam blocks, but it is also a significant step towards developing more sustainable and efficient industrial processes. Relying on this machine means entrusting the production of your EPS foam blocks to a fast, reliable, and cost-effective solution, which ultimately leads to maximized productivity and profitability in your operations. Trust in Dongshen’s innovation to meet and exceed your industry's requirements.