100% Original Factory Exterior Cornice Moulding - EPS foam panel making machine made in china – DONGSHEN

100% Original Factory Exterior Cornice Moulding - EPS foam panel making machine made in china – DONGSHENDetail:

Product Details

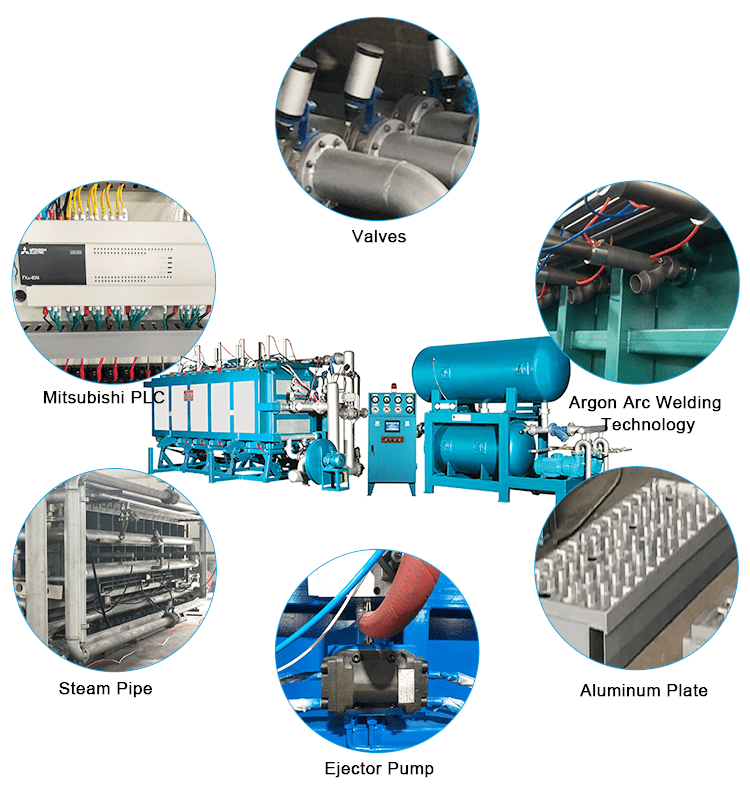

EPS foam panel making machine made in china advantages:

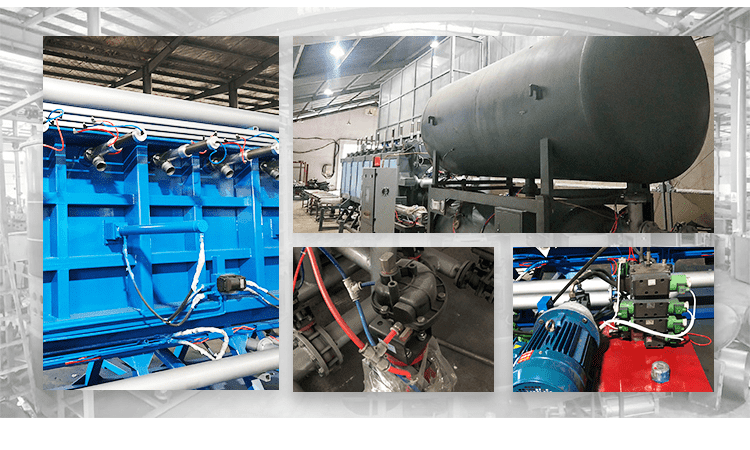

1.Machine is made of high-strength square tubes and thick steel plates;

2.Machine uses 5mm thick aluminum steam plates with Teflon coating. And under aluminum plate, bigger sized supports at more quantity are placed to avoid aluminum plate deform under high pressure. Aluminum plates doesn’t change form after ten years working;

3.Machine’s all six panels are through heat treatment to release welding stress, so that panels cannot deform under high temperature;

4.Machine with more steam lines to ensure steaming even in blocks, so block fusion is better;

5.Machine plates are with better drainage system so blocks are more dried and can be cut in short time;

6.All machine plates through rust removing, ball spraying, then do anti-rust base painting and surface painting, so machine body is not easy to get rusted;

7.Machine use smart piping system and steaming process, ensuring good fusion of blocks both for high density and low density;

8.Fast filling system and efficient vacuum system ensures machine fast working, each block 4~8 minutes;

9.Ejection is controlled by hydraulic pump, so all ejectors push and return at same speed;

10.Most components used in the machine are imported or famous branded products.

Main Technical Parameters

Item | Unit | PB2000V | PB3000V | PB4000V | PB6000V | |

Mould Cavity Size | mm | 2040*1240*1030 | 3060*1240*1030 | 4080*1240*1030 | 6100*1240*1030 | |

Block Size | mm | 2000*1200*1000 | 3000*1200*1000 | 4000*1200*1000 | 6000*1200*1000 | |

Steam | Entry | Inch | 2’’(DN50) | 2’’(DN50) | 6’’(DN150) | 6’’(DN150) |

| Consumption | Kg/cycle | 25~45 | 45~65 | 60~85 | 95~120 |

| Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

Compressed Air | Entry | Inch | 1.5’’(DN40) | 1.5’’(DN40) | 2’’(DN50) | 2’’(DN50) |

| Consumption | m³/cycle | 1.5~2 | 1.5~2.5 | 1.8~2.5 | 2~3 |

| Pressure | Mpa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

Vacuum Cooling Water | Entry | Inch | 1.5’’(DN40) | 1.5’’(DN40) | 1.5’’(DN40) | 1.5’’(DN40) |

| Consumption | m³/cycle | 0.4 | 0.6 | 0.8 | 1 |

| Pressure | Mpa | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 |

Drainage | Vacuum Drain | Inch | 4’’(DN100) | 5’’(DN125) | 5’’(DN125) | 6’’(DN150) |

| Down Steam Vent | Inch | 4’’(DN100) | 5’’(DN125) | 6’’(DN150) | 6’’(DN150) |

| Air Cooling Vent | Inch | 4’’(DN100) | 4’’(DN100) | 6’’(DN150) | 6’’(DN150) |

Capacity 15kg/m³ | Min/cycle | 4 | 5 | 7 | 8 | |

Connect Load/Power | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Overall Dimension (L*H*W) | mm | 5700*4000*2800 | 7200*4500*3000 | 11000*4500*3000 | 12600*4500*3100 | |

Weight | Kg | 5000 | 6500 | 10000 | 14000 | |

Case

Video

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for100% Original Factory Exterior Cornice Moulding - EPS foam panel making machine made in china – DONGSHEN, The product will supply to all over the world, such as: Israel, Vietnam, United Arab Emirates, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.