Umkhiqizi Womkhuhlane we-EPS WOKWO ebhokisini lezinhlanzi

Amapharamitha amakhulu womkhiqizo

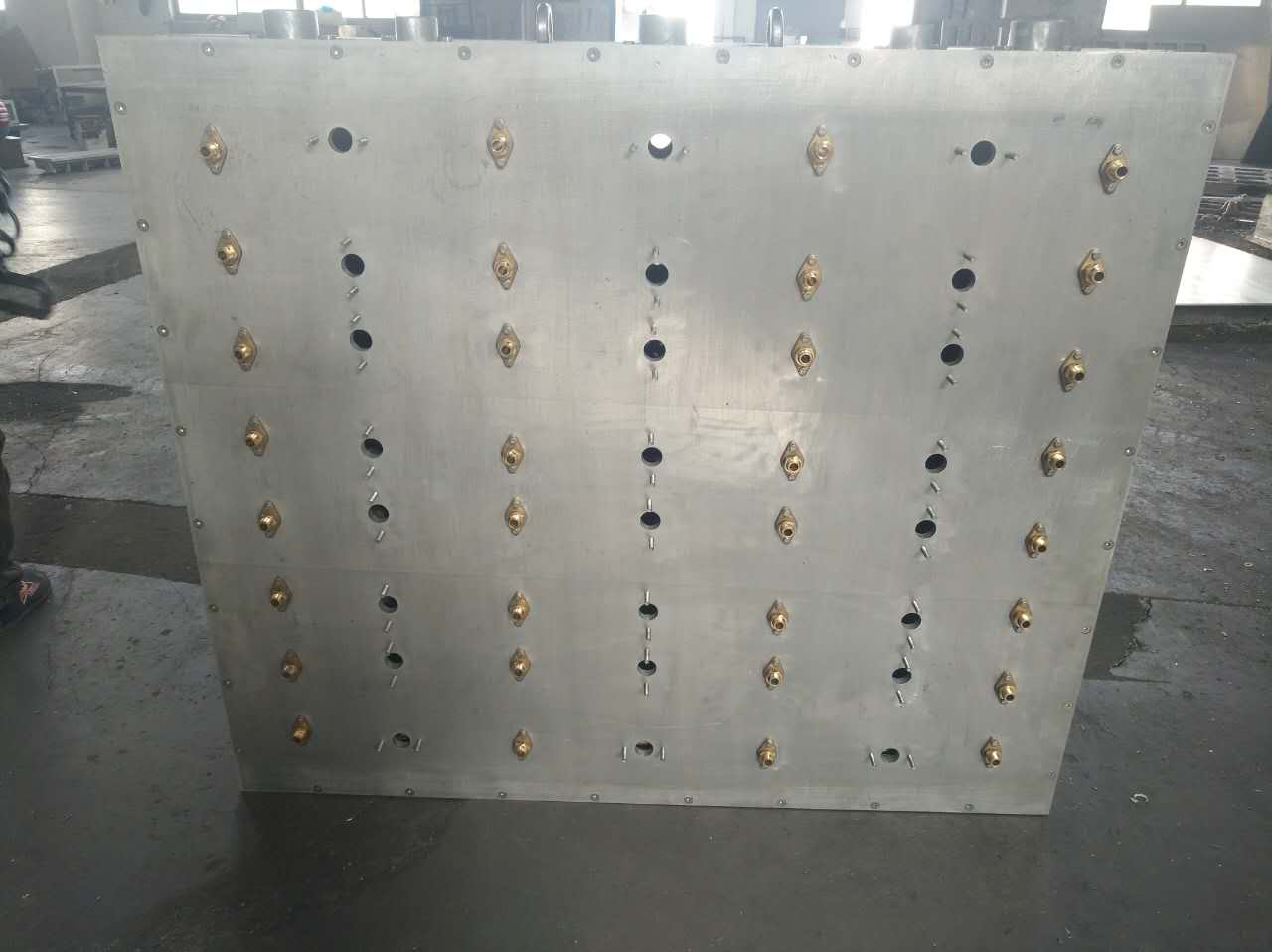

| Igumbi leSteam | 1200 * 1000mm, 1400 * 1200mm, 1600 * 1350mm, 1750 * 1450mm |

|---|---|

| Ubukhulu be-Mold | I-1120 * 920mm, 1320 * 1120mm, 1520 * 1270mm, 1670 * 1370mm |

| Ukuningabhotha | Izinkuni noma i-PU ngu-CNC |

| Ukufakaza | I-CNC ephelele |

| Ubukhulu bepuleti ye-aluminium | I-15mm |

| Ukufaka ndawonye | I-Plywood Box |

| Isikhathi sokuthumela | 25 ~ 40 izinsuku |

Ukucaciswa komkhiqizo okujwayelekile

| Into uqobo lwayo | Phezulu - Ikhwalithi ye-aluminium |

|---|---|

| Ukubekezela | Ngaphakathi kwe-1mm |

| Umgwengwezi | Teflon ukudedela okulula |

Inqubo Yokukhiqiza Umkhiqizo

Ukukhiqizwa kwezikhunta ze-EPS kubandakanya inqubo enemininingwane yokubunjiniza nokuklama. Ekuqaleni, umkhiqizo owuthandayo uqondiwe futhi waklanywa kusetshenziswa isoftware ye-CAD ukuqinisekisa ukunemba okucacayo. Izici ezibalulekile njengokugeleza kwezinto ezibonakalayo namanani okupholisa kubhekwa ngesikhathi sesigaba sokuklama. Lapho ukuklanywa sekuphothuliwe, imishini ye-CNC yakha isikhunta kusuka phezulu - Ikhwalithi ye-aluminium emabhulokini, ukuqinisekisa ukunemba. Ngemuva kokuqanjwa, isikhunta siyabuthana futhi sihlolwe kanzima, sibhekene necala lokuya enkantolo ukuqinisekisa ukuthi bahlangabezana namazinga ezimboni. Lezi zinqubo ziqinisekisa ukuthi isikhunta sihlala isikhathi eside, sisebenza kahle, futhi siyakwazi ukukhiqiza imikhiqizo eqondile ye-APS.

Izimo zohlelo lokusebenza zomkhiqizo

Izikhunta ze-EPS ziyaguquguquka futhi zisetshenziswe kabanzi emikhakheni ehlukahlukene. Ekwakhiweni, babalulekile ekukhiqizeni amaphaneli wokufakelwa kanye namabhulokhi enziwe ngokhonkolo. Imboni yokupakisha ithembele ku-EPS isikhunta sokwakha izinto zokufaka zokuvikela, ezibalulekile zokuvikela ama-elekthronikhi nezinye izimpahla ezintekenteke. Ezimpahleni zabathengi, izikhunta ze-EPS zisetshenziselwa ukukhiqiza izinto ezinjenge-Coolers nefenisha engasindi. Ukuzivumelanisa nezimo zabo kanye nokunemba kubenza babaluleke kakhulu kule mikhakha, bedlala indima ebalulekile ekuqinisekiseni ikhwalithi yomkhiqizo nokuvumelana.

Umkhiqizo Ngemuva - Insizakalo Yokuthengisa

Emuva kwethu - Insizakalo yokuthengisa ifaka ukwesekwa okuphelele, okunikeza izinsizakalo zokulungiswa kanye nokulungisa isikhunta sezikhunta zakho ze-EPS ziyaqhubeka zisebenza ekusebenzeni kahle. Ochwepheshe bethu abanolwazi bayatholakala ekuxazululeni inkinga futhi banikeze ukuholwa kwezobuchwepheshe. Siphinde futhi sinikeze isikhathi sewaranti lapho iqembu lethu lizosiza khona ekubhekaneni nanoma yiziphi izici zokukhiqiza noma izindaba ngokushesha.

Ukuhamba komkhiqizo

Izikhunta ze-EPS zigcwele ngokuphephile emabhokisini ePlywood ukuqinisekisa ukuthutha okuphephile. Sisebenzisana nabalingani be-Logiable Logistics ukuze baqinisekise ngesikhathi esifanele futhi ukulimala - Ukulethwa kwamahhala, ukuhlinzeka ngemininingwane yokulandelela ukuze kube lula kuwe.

Izinzuzo Zomkhiqizo

- Ukunemba okuphezulu ngenxa yemishini ye-CNC

- Ihlala isikhathi eside, eyenziwe kusukela kuqala - i-aluminium yeklasi

- Ukulethwa okusheshayo nokuhlolwa kwekhwalithi okuqinile

- Idizayinelwe ochwepheshe bezimboni ngeminyaka engaphezu kwengu-20 yesipiliyoni

I-FAQ yomkhiqizo

- Q1: Yikuphi okusetshenziswayo okusetshenziselwa isikhunta se-EPS?

I-A1: Sisebenzisa okuphezulu - Ikhwalithi ye-Aluminium Ingots ukuzokwenza izibungu zethu, ukuqinisekisa ukuqina kanye nesikhathi eside sokuphila isikhathi eside. Izikhunta zethu zenzelwe ukumelana nobunzima bokusetshenziswa okuphindaphindiwe, ukuzenza zilungele izinhlelo ezahlukahlukene zezimboni. - Q2: Kunembe kangakanani izikhunta ze-EPS ezenziwa?

I-A2: Izikhunta zethu ze-EPS zicutshungulwa ngokuphelele kusetshenziswa imishini ye-CNC, zithola ukubekezelelana ngaphakathi kwe-1mm. Lokhu okunembile kuqinisekisa ukuthi imikhiqizo yokugcina ye-EPS ihlangabezana nokucaciswa okuqondile kanye namazinga ekhwalithi adingekayo ezimbonini ezahlukene. - Q3: Ngabe isikhunta se-EPS senziwe ngokwezifiso ngokuya ngezidingo ezithile?

I-A3: Yebo, njengomenzi wesikhunta wokubumba ophelele, singakwazi ukuklama isikhunta ngokwezifiso ukuze sihlangabezane nezidingo ezithile zeklayenti. Onjiniyela bethu abanolwazi baguqula amasampula amakhasimende abe yi-CAD enemininingwane ye-CAD noma i-3D design yokukhiqizwa okuhambisanayo. - Q4: Yisiphi isikhathi sokulethwa esilinganiselwe saba isikhubungu se-EPS?

I-A4: Isikhathi sokulethwa kwesinye isikhathi siphakathi kwezinsuku ezingama-25 kuye kwangama-40, kuya ngobulukhuni bedizayini yokubumba kanye nesilinganiso sokukhiqiza. Silwela ukufeza imikhawulo yamakhasimende kahle. - Q5: Ngabe isikhunta sakho siyahambisana nemishini ye-EPS evela emazweni ahlukene?

I-A5: Yebo, sinokuhlangenwe nakho okubanzi kokuqamba izikhunta zamaShayina, amaJapan, amaJapan, amaKorea, nemishini ye-Jordani, eqinisekisa ukuhambisana kwezinhlelo ezahlukahlukene. - Q6: Iyiphi indlela yokupakisha yokuthumela isikhunta se-eps?

A6: Sipakisha isikhunta sethu emabhokisini ahlala isikhathi eside ePlywood ukuze abavikele ngesikhathi sokuhamba. Le ndlela ivikela ukulimala, ukuqiniseka ukulethwa okuphephile endaweni yakho. - Q7: Uyakunikeza yini iwaranti ezikhunjini ze-EPS?

I-A7: Yebo, sinikeza isikhathi sewaranti lapho sihlanganisa khona iziphambeko zokwakha. I-After yethu ye-After - Ithimba lesevisi yokuthengisa liyatholakala nganoma yikuphi ukulungiswa okudingekayo noma ukwesekwa. - Q8: Uqinisekisa kanjani ikhwalithi yezikhunta zakho ze-EPS?

A8: Izindlela zethu zokulawula ikhwalithi ziyaqina, zimboza zonke izigaba kusuka ekulathini, ekuphonseni, kumakhenishini, ukuhlanganisa. Isikhunta ngasinye sithola ukuhlolwa okuqinile kokuphezulu okuphezulu okuphezulu - Ukukhishwa kwekhwalithi. - Q9: Ungasiza yini ukuklama ukusetha okusha kwe-EPS Factory Setup?

I-A9: Yebo, iqembu lethu lobuchwepheshe elinolwazi lingasiza ekwakheni ukusetha okusha kwe-EPS Factory, ukuhlinzeka nge-Turn ephelele - Izisombululo ezibalulekile ukuthuthukisa ukusebenza kahle kanye namandla. - Q10: Yikuphi ukucatshangelwa kwemvelo kokukhiqiza isikhunta se-EPS?

I-A10: Sizibophezele emikhubeni esimeme ngokuhlola izinto ezisetshenzisiwe futhi sithuthukise ukusebenza kwamandla ekusebenzeni kwethu ukunciphisa umthelela wezemvelo ngenkathi kugcinwa amazinga aphezulu okukhiqiza.

Izihloko ezishisayo zomkhiqizo

- I-CNC inembe kanjani ithuthukisa ukukhiqiza isikhunta se-EPS

Ukuhlanganiswa kwemishini ye-CNC ekukhiqizeni isikhunta sokukhulisa kuqinisa ngokunemba nokusebenza kahle. Imashini ye-CNC ivumela ukulawula okuqondile kwenqubo yokudala yokudala, ukunciphisa iphutha lomuntu kanye nokuqinisekisa ukuthi wonke isikhunta sinamathela emazingeni okubekezelela, ngokuvamile ngaphakathi kwe-1mm. Lokhu kucacisa kubalulekile ekukhiqizeni imikhiqizo eyinkimbinkimbi ye-EPS edinga ubukhulu kanye nekhwalithi. Ubuchwepheshe obuthuthukisiwe bemishini ye-CNC busheshise ukukhuphuka kwezikhathi zokukhiqiza, buza ukulethwa okusheshayo ngaphandle kokuyekethisa ngekhwalithi. Njengomenzi wesikhunta we-EPS wokubumba, ukunemba kwe-CNC kubalulekile ukuze kugcinwe inzuzo yokuncintisana nokuhlangana okulindelwe kweklayenti emikhakheni ehlukahlukene yezimboni.

- Iqhaza le-aluminium kuma-detable eps isikhunta

I-Aluminium iyisitatimende esithandwayo ekwenziweni kwezikhunta ze-EPS ngenxa yokuqina kwayo kanye nezindawo ezingasindi. Ukusebenza kwayo okuhle kakhulu kanye nokumelana nokugqwala kokugqwala kwenze kube kuhle ukubekezelela ukufudumeza okuphindaphindayo nemijikelezo yokupholisa ngesikhathi sokukhiqiza i-EPS. Ngaphezu kwalokho, isikhunta se-aluminium kulula ukusiphatha, ukunciphisa izindleko zabasebenzi kanye nokwenza ngcono ukusebenza kahle. Njengomkhiqizi wokubumba okuphelele we-EPS, usebenzisa i-High - I-Aluminim Yekhwalithi iqinisekisa ukuthi isikhunta sethu sigcina isikhathi eside futhi silethe imiphumela engaguquki ngaphansi kwezimo zezimboni. Ngokwengeziwe, ukungasebenzi kahle kwe-aluminium axhumanisa ngezindlela zokukhiqiza ezisimeme, ukubhekana nokukhathazeka okukhulayo kwemvelo.

- Ukusimama Kwezemvelo ekukhiqizeni isikhunta se-EPS

Ngokwanda kokuhlolisisa emiphumeleni yezemvelo, abakhiqizi be-EPS Mold baqala ukwenza imisebenzi eqhubekayo. Lokhu kufaka phakathi ukusetshenziswa kwezinto ezisetshenziswayo ekukhiqizeni isikhunta nokutshala imali emandleni - imishini esebenza kahle yokunciphisa imidwebo yekhabhoni. Ngaphezu kwalokho, ukuthuthukisa ezinye izindlela ze-biodegradable kwimikhiqizo yendabuko ye-EPS iyathola ukugcwala. Imizamo enjalo ayigcini nje ngokunciphisa imfucuza kodwa futhi idlulisela phambili kwi-eco - amaklayenti abazi, eqinisekisa ukulingana phakathi kwezimfuno zezimboni kanye nomsebenzi wemvelo. Njengomenzi wesikhunta onke wokubumba, sihlala sizibophezele kule mikhuba, sisiza ekuveleni indlela yekusasa eliluhlaza okokwenziwa.

- Isikhunta se-EPS se-EPS: Izidingo Zomhlangano Ezihlukahlukene

Amandla wokwenza isikhunta se-EPS sangokwezifiso sibalulekile ekubhekaneni nezidingo ezithile zezimboni ezahlukahlukene. Ukusuka ekwakheni izimpahla zabathengi, emkhakheni ngamunye ucela ukwakheka okuhlukile kokubumba okuhambisana nezicelo zabo. Ukwenza ngokwezifiso kufaka ukuguqula amasampula eklayenti abe amamodeli aqondile e-CAD noma amamodeli we-3D, aqinisekise ukuthi wonke isikhunta sihlangabezana nokucaciswa ngqo. Lokhu kunamandla kuthuthukisa ukukhiqizwa kokukhiqizwa kanye nokusebenza kahle, okunika amandla amabhizinisi ukusungula nokuzivumelanisa nezitayela zemakethe. Njengomenzi wesikhunta wokuphila ohamba phambili, sibeka phambili ukwenza ngokwezifiso ukuhlinzeka ngezisombululo ezihambisana nezidingo ezisebenzayo zamakhasimende ethu kanye nezinhloso zamasu.

- Ukulungiselela ukukhiqizwa nge-EPS yokulondolozela ukulungiswa

Ukulondolozwa njalo kwezikhunta ze-EPS kubalulekile ekusekeleni ukusebenza kahle kokukhiqizwa kanye nokugcina isikhathi sokuphila. Ukuhlola okujwayelekile Khomba ukugqoka nokuklebhula okungathinta ukunemba komkhiqizo wokugcina we-EPS. Njengomenzi wokubumba ophelele we-EPS, sincoma indlela esebenzayo yokulungiswa kokubumba, kubandakanya nokuhlanzwa, ukuthambisa, kanye nokuhlolwa ngezikhathi ezithile. Lo mkhuba awuvimbi nje kuphela isikhathi sokudla okubizayo kepha futhi uqinisekisa ikhwalithi eguqukayo kuyo yonke i-batch yokukhiqiza, ephakamisa amazinga aphezulu embonini ye-EPS. Emuva kwethu - Insizakalo yokuthengisa ifaka ukwesekwa okuphelele kokulungiswa kokusiza amabhizinisi ekwakheni imisebenzi yawo yokukhiqiza e-EPS.

- Umthelela wokulawulwa kwekhwalithi ekukhiqizeni isikhunta se-EPS

Ukulawulwa kwekhwalithi kuyisici esibucayi sokukhiqiza isikhunta e-EPS, ukuqinisekisa ukuthi isikhunta ngasinye sihlangabezana namazinga embonini aqinile. Lokhu kubandakanya ukuhlolwa okuphelele nokuhlola esigabeni ngasinye sokukhiqizwa, kusuka emklameni wokuqala kuya emhlanganweni wokugcina. Njengomenzi wesikhunta wokubumba okuphelele, izindlela zethu zokulawula ezisezingeni eliphakeme zifaka phakathi ukuqulwa kwecala kanye nezinguquko ekuhlaziyeni ukusebenza kwesikhunta, kuqinisekisa ukuthembeka nokunemba komkhiqizo ngamunye. Ukuqinisekiswa kwekhwalithi eqinile akugcini nje ngokuqinisa ukuqiniseka kwamakhasimende kepha futhi kunciphisa ubungozi obunzima emikhiqizweni yokugcina ye-EPS, okuholela ekwenziweni kokweneliseka kwamakhasimende nokwethembeka komkhiqizo.

- Izinto ezintsha ku-EPS Mild Heat Transfer kahle

Ukuthuthukisa ukusebenza kahle kokushisa ku-EPS isikhunta kungaholela ekuthuthukisweni okukukhulu kwijubane lokukhiqiza kanye nokusetshenziswa kwamandla. Lokhu kufaka ukunxusa ukwakheka kwesikhunta ukwenza lula ngisho nokushisa nokupholisa, ukunciphisa izikhathi zomjikelezo nokukhuphula okubandayo. Izinto ezithuthukisiwe nezimbobo, ezinjenge-teflon, zidlala indima ekwenzeni ngcono ukukhishwa kwemikhiqizo ye-EPS kusuka ekubumbeni, okuthuthukisa okunye ukusebenza kahle. Njengomenzi wesikhunta wokubumba okuphelele, siqhubeka sihlola izixazululo ezintsha zokwandisa ukudluliswa kokushisa, ukuvumelanisa nezinqubo zethu zokukhiqiza ngentuthuko yesimanje yezobuchwepheshe ukuletha ukusebenza kwesikhunta okuphezulu.

- IZINSELELE NEZINSELELE E-EPS Mold Sokulunza Kwezifiso

Ngokwezifiso isikhunta se-EPS siveza izinselelo ezinjengokuqinisekisa ukuhambisana nezinhlelo zokukhiqiza ezikhona kanye nokuhlangana nezidingo ezithile zokuklama amaklayenti. Lezi zinselelo zidinga ukuqonda okuphelele kwezinto ezahlukahlukene, amakhono aqondile e-cad, namakhono amamashini athuthukile. Njengomenzi wesikhunta we-EPS isikhunta, sibhekana nalezi zinselelo ngokufaka isipiliyoni sethu esibanzi semboni kanye nobungcweti. Iqembu lethu lisebenzisana kakhulu namakhasimende ukuhambisa isikhunta ezidingweni zawo, ekunqobeni izithiyo ngokusebenzisa izixazululo zobunjiniyela ezintsha kanye nemikhuba yokuqinisekiswa kwekhwalithi eqinile, ukuqinisekisa ukuthi ukwenza ngokwezifiso kuthuthukisa ukukhiqizwa.

- Ikusasa lokukhiqiza isikhunta se-EPS

Intuthuko kwezobuchwepheshe kanye nesayensi yezezinto zokwakha ibumba ikusasa lokukhiqiza isikhunta se-EPS, ngokugxila kwi-automation, ukusebenza kahle, kanye nokusimama. Ubuchwepheshe obuqhamukayo obufana ne-AI - I-Druven Design kanye nokuphrinta kwe-3D kungaguqula ukukhiqizwa kwesikhunta, kunikeza amazinga amasha okunemba nokwenza ngokwezifiso. Njengoba ukucatshangelwa kwezemvelo kuyaqhubeka nokuba nomthelela ekwenziweni, imikhuba esimeme nokuqamba izinto ezibonakalayo kuzodlala indima enkulu. Njengesakhiwo - Ukucabanga okuthengiswayo okuphelele kwe-EPS isikhunta, sihlala ngaphambili kwalezi zindlela, ukutshala imali ocwaningweni nasekuthuthukisweni ukuze sinikeze ukusika - izixazululo ezinqenqemeni ezihlangabezana nezidingo zezimboni.

- Ukuqonda ukuphathwa kwezimpilo ze-EPS Mold Lifecycle

Ukuphatha i-Lifecycle of EPS isikhunta esinamasu kusuka ekwakhiweni kuya kokulahlwa, ukuqinisekisa ukuthi isikhunta ngasinye sisetshenziswa kahle nangokuzinzile. Lokhu kufaka amasheduli wokulungiswa njalo, ukuqapha ukusebenza kwendlela yokusebenza, kanye nokwenza kahle kwezindlela zokusebenza. Ekupheleni kwesikhunta sokuphila kwesikhunta, ukuphinda usebenzise kabusha noma ukuphindisela izinto zayo kungaba nomthelela ezinhlosweni zokukhiqiza ezisimeme. Njengomenzi wesikhunta wokubumba okuphelele, sigqugquzela amasu aphelele wokuphathwa kwezifiso okuthuthukisa ukukhulisa isikhathi eside, anciphise umthelela wezemvelo, kanye namabhizinisi asekela ukulondolozwa kwezinhlaka zokukhiqiza ezinomthwalo wemfanelo.

Incazelo Yezithombe

Ayikho incazelo yezithombe yalo mkhiqizo