Izisombululo eziphakeme ze-EPS zivimba izixazululo zokubumba kusuka kumkhiqizi we-ejector oholayo, i-dongshen

Imininingwane Yomkhiqizo

I-Polystyrererene block umshini wokubumba nge-vacuum ngumshini we-EPS osebenzayo ukwenza amabhlogo we-eP. Amabhulokhi e-EPS anganqunywa kumashidi wokufakelwa kwendlu noma ukupakisha. Imikhiqizo ethandwayo eyenziwe ngamashidi e-EPS amaphaneli we-sandwich e-EPS, amaphaneli we-3D, amaphaneli we-wangaphakathi nangaphandle odongeni, ukupakisha ingilazi, ukupakishwa kwefenisha, ukupakisha ifenisha, ukupakisha ifenisha, ukupakisha ifenisha njll.

Umshini wokubumba we-polystyrene block nge-vacuum ungakhiqiza amabhlogo aphezulu we-EPS, asebenza kumjikelezo osheshayo, futhi wonke amabhlogo aqondile futhi aqinile futhi anomswakama wamanzi aphansi. Umshini nawo ungenza amabhlokhi aphansi aphansi ngekhwalithi enhle. Kungenza ubukhulu obuphezulu ku-40g / l kanye nobuningi obuphansi ku-4G / l.

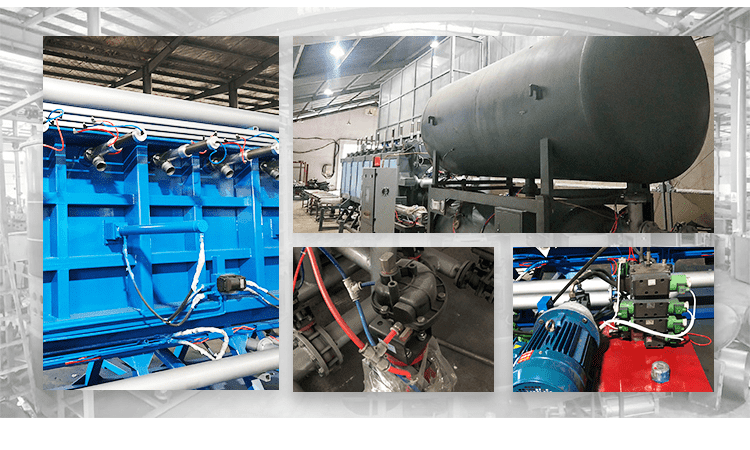

I-Polystyrererere Block Machine ngokubumba nge-vacuum ephelele ngomzimba womshini omkhulu, ibhokisi lokulawula, uhlelo lwe-vacuum, uhlelo olunesisindo njll.

I-Polystyrere Block Machine yokubumba ngezinzuzo ze-vacuum:

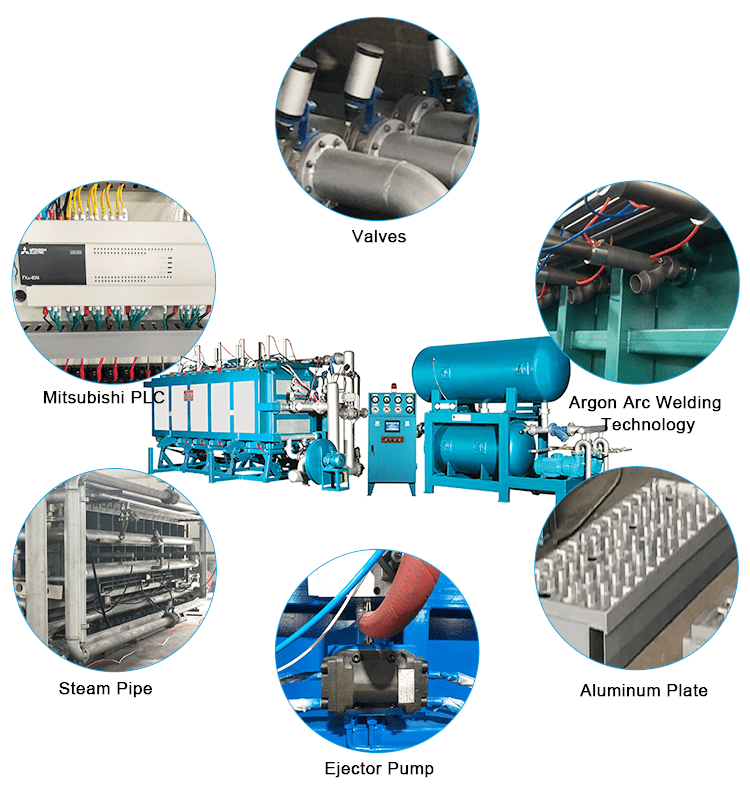

I-1.Machine yenziwa nge-High - Amashubhu Squent Square namapuleti ensimbi athambile;

I-2.Machine isebenzisa amapuleti ama-aluminium awugqinsi ama-aluminium ama-aluminium anama-teflon. Futhi ngaphansi kwepuleti ye-aluminium, ukwesekwa okukhulu kwesayizi ngenani elingaphezulu kubekwa ukugwema ukuguquguquka kwepuleti ye-aluminium ngaphansi kwengcindezi ephezulu. Amapuleti we-aluminium ayashoni't Shintsha ifomu ngemuva kweminyaka eyishumi esebenza;

I-3.Machine'ama-s kuwo wonke amaphaneli ayisithupha ngokushisa ukwelashwa kokukhipha ukucindezelwa kwe-welding, ukuze amaphaneli awakwazi ukuguqula ngaphansi kokushisa okuphezulu;

I-4.Machine enemigqa ye-Steam engaphezulu ukuze iqinisekise ukushaya ngisho nasemabhulokini, ngakho-ke ukuvinjezelwa ukufuya kungcono;

Amapuleti angama-5.Machine anohlelo olungcono lwe-drainage ngakho-ke amabhlokhi omisiwe futhi anganqunywa ngesikhathi esifushane;

Izitezi ze-6.ALL Machine ngokususa ukugqwala, ukufafaza kwebhola, bese wenza i-anti - ukupenda isisekelo sokugqwala nokupenda okungaphezulu, ngakho-ke umzimba womshini akulula ukugcwala;

7.Machine sebenzisa uhlelo lwe-smart piping kanye nenqubo yokuntshontsha, ukuqinisekisa ukuhlanganiswa okuhle kwamabhulokhi zombili ngobuningi obuphezulu nobuningi obuphansi;

8. Ifasidi lokugcwalisa kanye nohlelo olusebenzayo lwe-vacuum luqinisekisa ukusebenza komshini ngokushesha, ibhlokhi ngayinye 4 ~ 8 imizuzu;

I-9.Yeved ilawulwa yi-hydraulic pump, ngakho-ke wonke ama-ejectors acindezele futhi abuye ngejubane elifanayo;

10.Izakhi ezisetshenziswa emshinini zingenisa noma imikhiqizo edumile enophawu.

Amapharamitha aphambili wezobuchwepheshe

Into yendaba | Umuvo | I-PB2000V | I-PB3000V | I-PB4000V | I-PB6000V | |

Usayizi we-mold cavity | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | I-6100 * 1240 * 1030 | |

Ubukhulu Bokuvimba | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | I-6000 * 1200 * 1000 | |

Isitimu | Ukufaka | Umuthi ophakathi | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Ukudliwa | Kg / umjikelezo | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Ukucindezela | I-MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Umoya ocindezelwe | Ukufaka | Umuthi ophakathi | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Ukudliwa | m³ / umjikelezo | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Ukucindezela | I-MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Amanzi Okupholisa Okupholisa | Ukufaka | Umuthi ophakathi | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Ukudliwa | m³ / umjikelezo | 0.4 | 0.6 | 0.8 | 1 | |

Ukucindezela | I-MPA | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Udonga | I-Vacuum Drain | Umuthi ophakathi | 4 '' (DN100) | I-5 '' (DN125) | I-5 '' (DN125) | 6 '' (DN150) |

Down Steam Vent | Umuthi ophakathi | 4 '' (DN100) | I-5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Umoya wokupholisa umoya | Umuthi ophakathi | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Amandla 15kg / m³ | Min / umjikelezo | 4 | 5 | 7 | 8 | |

Xhuma umthwalo / amandla | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Ubukhulu obuphelele (L * h * w) | mm | I-5700 * 4000 * 2800 | I-7200 * 4500 * 3000 | 11000 * 4500 * 3000 | I-12600 * 4500 * 3100 | |

Isisindo | Kg | 5000 | I-6500 | I-10000 | 14000 | |

Icala

Ividiyo ehambisanayo

As an Eps Ejector Manufacturer, our machine's design incorporates a vacuum system, ensuring precise moulding of EPS blocks. This feature provides remarkable savings in terms of time and energy, contributing to an eco-friendly manufacturing process. Our product is not just about making EPS blocks; it's about delivering quality, efficiency, and sustainability in every block produced. At DongShen, we understand the needs of the industry. Our commitment as an Eps Ejector Manufacturer goes beyond just delivering machines; we provide full-fledged solutions to assist our clients in enhancing their manufacturing capabilities. By choosing our Polystyrene block moulding machine with vacuum, you choose superior performance, quality, and sustainability. Explore our innovative product range and make a smart choice for your business. Partner with DongShen, your trusted Eps Ejector Manufacturer, to leverage the power of advanced block moulding solutions.