Ukuphakama - Ukusebenza kakuhle kombane I-Polystrene block yomatshini

Iinkcukacha zemveliso

I-Polystyrene Vebyrene Vebyrene ibhloka kunye ne-vacuum ngumatshini osebenzayo we-EPS ukwenza iibhloko ze-EPS. Iibhloko ze-EPS zinokunqunyulwa kumashiti okuhlala kwindlu okanye ukupakisha. Iimveliso ezithandwayo ezenziwe kwiimakhishithi ze-EPS ziiphaneli zesandwich, iiphaneli ezi-3D, zangaphakathi nangaphandle zodonga, ukupakisha kweglasi, ukupakisha ifeksi, ukupakisha ifeksi, ukupakisha ifeksi, ukupakisha ifenitshala, i-phangeli ye-Njl.

I-Polystyrene Vebyrene Vebyrene ibhloka kunye ne-vacuum inokuvelisa iibhloko ze-EPS eziPhezulu, ezisebenza kumjikelo we-EPS, kwaye zonke iibhloko zithe tye kwaye zomelele kwaye zomelele kwaye zomelele kwaye zomelele kwaye zomelele kwaye zomelele kwaye zinamandla okufuma kwamanzi. Umatshini unokwenza iibhloko zokuxinana ezisezantsi ngomgangatho olungileyo. Inokwenza uxinzelelo oluphezulu kwi-40g / l kunye noxinzelelo oluphantsi kwi-4G / l.

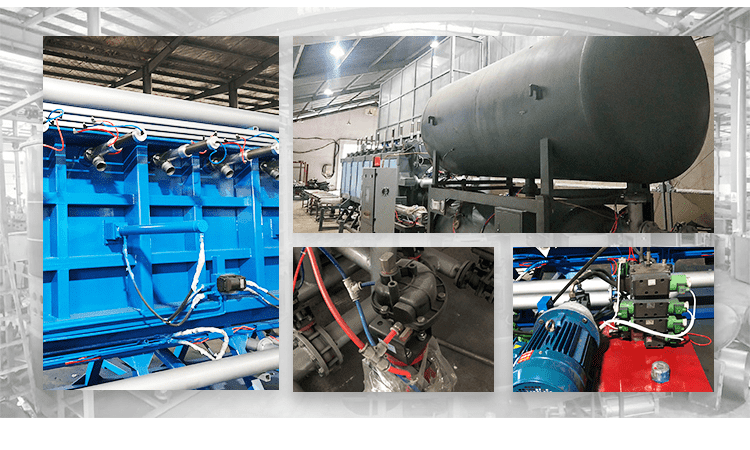

I-Polystyrene Vebyrene ibhloka ngokugcwaliswa kwe-vacuum igqibe iZiko lomatshini eliphambili, ibhokisi yolawulo, inkqubo ye-vacuum, inkqubo yobunzima njl.

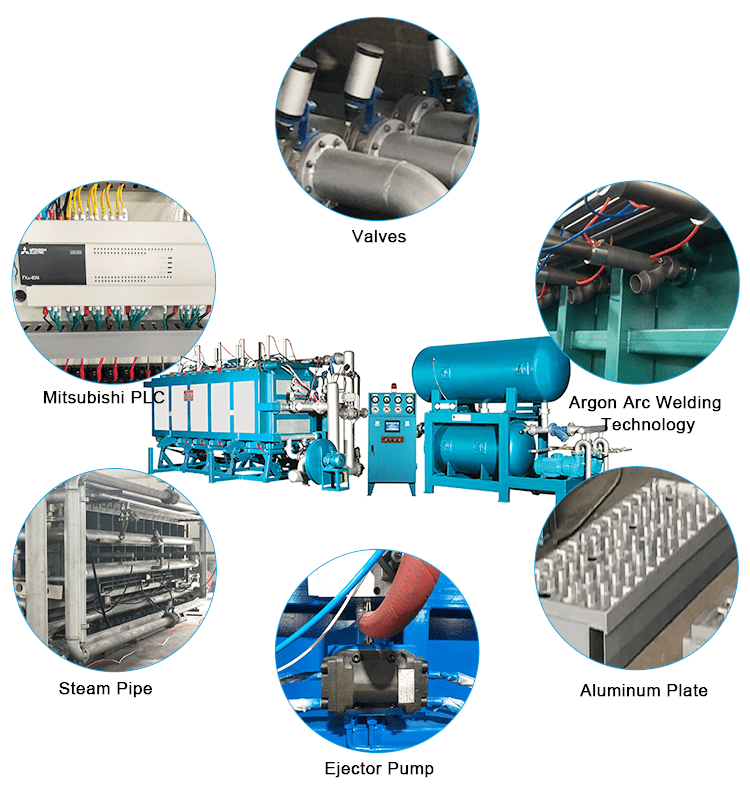

I-Polystrene block yomatshini wokubumba kunye nezibonelelo ze-vacuum:

I-1.minachine yenziwe phezulu - Amandla amaqhekeza kunye neepleyiti zentsimbi;

2.Machine isebenzisa i-5mm i-5mm i-aluminium steam plets ene-teflon yokuqesha. Ngaphantsi kweplate ye-aluminium, inkxaso enkulu ye-SIGGER ngenani elingaphezulu kokunqanda iplagi ye-Aluminium destem phantsi koxinzelelo oluphezulu. I-Aluminium plates i-alumini't Tek tshintsha ifomu emva kweminyaka elishumi ukusebenza;

3.Machine'Zonke iiphaneli ezintandathu zisebenzisa unyango lobushushu ukukhulula uxinzelelo lwelding, ukuze iipaneli azikwazi ukuthoba phantsi kobushushu obuphezulu;

4.Machine enemigca engaphezulu ye-Steam ukuqinisekisa ukuba ukuqhubela phambili kwiibhloko, ngoko bhitha i-fusion ilunge ngakumbi;

Iipleyiti ze-5michine zinenkqubo engcono yokuhambisa amanzi e-slobs yomiswe ngakumbi kwaye inokunqunyulwa ngexesha elifutshane;

6.Umatshini womatshini wokususa i-russis, ibhola itshiza, emva koko wenze i-anti - i-rust isiseko sepeyinti kunye nokupeyinta okungaphezulu, umzimba womatshini akalula ukuba agungqiswe;

7.Machine isebenzisa inkqubo ye-smart piiding kunye nenkqubo yokuqhubela, ukuqinisekisa ukufundela okufanelekileyo kweebhloko zombini zoxinzelelo oluphezulu kunye noxinizelelo olusezantsi;

8. Ukugcwalisa inkqubo kunye nenkqubo efanelekileyo yokuqhawula i-vacuum iqinisekisa ukusebenza ngokukhawuleza kumatshini, ibhloko nganye 4 ~ 8 imizuzu;

9.Ijewa ilawulwa yimpompo ye-hydraulic, ke zonke ii-ejeeties zityhala kwaye zibuye ngesantya esifanayo;

I-10 lezinto ezisetyenzisiweyo kumatshini zingeniswa ngaphandle okanye zidume iimveliso ezidumileyo.

Iiparamitha eziphambili

Into | Iyunithi | Pb2000V | I-PB3000V | I-PB4000V | I-PB6000V | |

Ubungakanani be-cavity | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | I-6100 * 1240 * 1030 | |

Ubungakanani bebhloko | mm | 2000 * 1200 * 1000 | I-3000 * 1200 * 1000 | I-4000 * 1200 * 1000 | I-6000 * 1200 * 1000 | |

I-steam | Ukungena | Intshi | 2 '(DN50) | 2 '(DN50) | 6 '(DN150) | 6 '(DN150) |

Ukuselwa | Kg / umjikelo | 25 ~ 45 | 45 ~ 65 | I-60 ~ 85 | I-95 ~ 120 | |

Uxinzelelo | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Umoya oxinzelelweyo | Ukungena | Intshi | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '(DN50) | 2 '(DN50) |

Ukuselwa | m³ / umjikelo | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Uxinzelelo | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Vacuum ukupholisa amanzi | Ukungena | Intshi | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Ukuselwa | m³ / umjikelo | I-0.4 | 0.6 | 0.8 | 1 | |

Uxinzelelo | Mpa | I-0.2 ~ 0.4 | I-0.2 ~ 0.4 | I-0.2 ~ 0.4 | I-0.2 ~ 0.4 | |

Amanzi | Vacuum drain | Intshi | 4 '(DN100) | 5 '(DN125) | 5 '(DN125) | 6 '(DN150) |

Phantsi i-steam vernt | Intshi | 4 '(DN100) | 5 '(DN125) | 6 '(DN150) | 6 '(DN150) | |

Ukupholisa umoya | Intshi | 4 '(DN100) | 4 '(DN100) | 6 '(DN150) | 6 '(DN150) | |

Umthamo we-15kg / m³ | Imizuzu / umjikelo | 4 | 5 | 7 | 8 | |

Qhagamshela umthwalo / amandla | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Ubukhulu becala (L * h * w) | mm | I-5700 * 4000 * 2800 | I-7200 * 4500 * 3000 | I-11000 * 4500 * 3000 | I-12600 * 4500 * 3100 | |

Ubunzima | Kg | I-5000 | I-6500 | I-10000 | I-14000 | |

Ityala

Ividiyo ehambelana nayo

Our technical team is committed to supporting you in mastering the functionality of the Electric Hot Wire Foam Cutter. We provide comprehensive training and post-purchase support to assist you in harnessing the full potential of this versatile machine. Invest in the future of EPS block moulding with the Electric Hot Wire Foam Cutter from Dongshen, a machine that embodies innovation, efficiency, and performance like none other in the market. Revolutionize your EPS manufacturing process with the advanced technology of our Polystyrene Block Moulding Machine. Experience the Dongshen difference today.