Umatshini wefektri yefeneli ye-polystyrene yomgangatho wepaneli

Iinkcukacha zemveliso

| Ubude | I-800 ~ 1380mm |

|---|---|

| Ububanzi | I-600 ~ 960mm |

| Ukuphakama | I-100mm |

| Ubungakanani bephepha | I-0.03 ~ 2mm |

| Isantya sokusebenza | I-2 ~ 3 panels ngomzuzu |

| Amandla | Pneumatic |

| Ubungakanani bomatshini | I-9200 * 3300 * 2100mm |

| Ubunzima | 4.8T |

Inkcazo yemveliso eqhelekileyo

| Isixhobo | I-EPS |

|---|---|

| Indlela yokufudumeza | I-cerarad ceramic |

| Indlela yokupholisa | Ezenzekelayo |

Inkqubo yeMveliso yeMveliso

Ngokutsho kophando lwegunya, inkqubo yokwenziwa kwe-polystyrene ibandakanya ukusebenza okusebenzayo kunye nokusebenza ngokuchanekileyo ukwenza iiphaneli ze-EPS ezisemgangathweni. Inkqubo iqala ngokwanda kweentlobano zePolystyrene Buds usebenzisa i-Steam - Ibumba eshushu. Oku kulandelwa ngokuguqula iiphaneli ezandisiweyo ngephepha le-hips usebenzisa i-infrared cerarad yokufudumeza ukuhanjiswa kobushushu obungafunekiyo. Umsebenzi uqukumbela ngeendlela zokupholisa ngokuzenzekelayo kunye nokuzama ukuqinisekisa ukuba iipaneli zihlangabezana neenkcazo ezinqwenelekayo. Ukukhutshelwa kwezenzekelayo kunciphisa imposiso yomntu kunye nexesha lokuvelisa ngelixa kusenziwa ukusetyenziswa kwezinto.

Imeko yesicelo semveliso

Kwiseto semizi-mveliso, ukusetyenziswa kweephaneli zokufudumeza kwe-EPS kuyanda ngenxa yepropathi yabo efanelekileyo yokufakelwa kunye nokuqina. Imithombo egunyazisiweyo ibalaselisa isicelo sabo sokwakha, ngakumbi ngeenkqubo zokufudumeza ngaphantsi apho zinegalelo ekusebenzeni nasekuthuthuzelweni kwamandla. Inkqubo yokwenziwa kwemveliso yePolystyrene iqinisekisa ukuba iipaneli zihlangabezana nemigangatho engqongqo yeshishini, ibenza bafaneleke kwiiprojekthi zominye zokuhlala nezorhwebo. Ezi phanezi zikwafumana ukusetyenziswa kwiindawo ezibandayo zokugcina kunye nokwakhiwa kwangaphambili ngenxa yendlela yabo yokukhanya kunye nendalo.

Imveliso emva - Inkonzo yokuthengisa

Sinikezela ngokuthile emva kwenkonzo yokuthengisa kubandakanya nenkxaso yokufakelwa, uqeqesho lolondolozo, kunye noncedo lwenkonzo yamaphepha-mvume angama-24/7 ukujongana nemicimbi yokusebenza. Iqela lethu lobugcisa liyafumaneka kwi - Inkonzo yesayithi Ukuqinisekisa ukusebenza kwezamashishini lakho kuhlala kugudile kwaye kuyasebenza ngokufanelekileyo.

Ukuhamba kwemveliso

Ukuhamba koomatshini bemveliso yethu yePolystyrene kuphathwa ngononophelo, kusetyenziswa ukupakishwa okwenziwe ngokukodwa ukuthintela umonakalo. Sisebenzisana neenkampani ezinokuthenjwa izinto ezinokuthenjwa ukuze ziqinisekise ngazo ukuhanjiswa ngexesha elifanelekileyo kwindawo yakho yefektri kwihlabathi liphela.

Izibonelelo zeMveliso

- Ngokuzenzekelayo ngokuzenzekelayo kumgangatho oqinisekileyo kunye nokuchaneka

- Ubungakanani ngokuthe ngqo kunye nobunzima bokufezekisa iimfuno ezithile zemveliso

- Amandla - Uyilo olusebenzayo ukunciphisa iindleko zomsebenzi wefektri

- Ulwakhiwo oluhlala luhleli luqinisekisa ixesha elide - Ukusetyenziswa kwethuba

Imveliso yemveliso

- Isebenza njani le nkqubo yokwandisa kulo matshini?Inkqubo yokwabhalisa ibandakanya ukusombulula ngokuzenzekelayo isakhelo sephaneli kwiphaneli ye-EPS, ukusebenzisa ubushushu, kwaye ukupholisa ukuqinisekisa ukubambelela kwephepha eliphezulu.

- Yeyiphi inkqubo yesondlo efunekayo?Ukucocwa rhoqo kunye nokuhlolwa kwezinto zokufudumeza kunye neenxalenye zoomatshini kuyacetyiswa, kunye nohlaziyo lwesoftware yexesha kwiinkqubo zolawulo.

- Ngaba lo matshini unakho ukudityaniswa kwimigca ekhoyo yefektri?Ewe, inokudityaniswa ngokulula ngoyilo oluyilo lwayo lokumongola, kwaye iqela lethu linokunceda ekulungelelaniseni kwiseti yakho yangoku.

- Ngaba uqeqesho lubonelelwe ngumqhubi?Ewe, uqeqesho olupheleleyo lubandakanyiwe ngokuthenga lomatshini, ukuqinisekisa ukuba abaqhubi banokuyisebenzisa ngokufanelekileyo nangokukhuselekileyo.

- Zeziphi izinto zokhuseleko eziqukiweyo?Umatshini ubandakanya amaqhosha okumisa ngokukhawuleza, oonogada bezokhuseleko, kunye nokuvalwa ngokuzenzekelayo - Ukucima iindlela ukuqinisekisa ukhuseleko lomqhubi ngexesha lokusetyenziswa.

- Ndingawenza Njani umatshini weemfuno zam ezithile?Sinikezela ngeendlela zokhetho ngokweziko ubukhulu, isantya, kunye neenkcazo zamandla ukuhambelana neemfuno zakho zemveliso.

- Lithini ixesha lokukhokela lokuzaliseka?Amaxesha akhokelayo ayahluka ngokuxhomekeka kwimveliso, kodwa aqala ukusuka kwiiveki ezi-6 ukuya kwezi-8.

- Zeziphi iintlobo zezixhobo ezinokuchithwa?Ezona zinto ziphambili ziipaneli ze-EPS kunye neekhilomitha, kodwa ezinye izinto ezinokuhlala kwisicelo.

- AMANYE AMANYE AMANYE AMANYE AMANYE AMANYE AMAZWI?Yenziwe ngamandla - Ukugcina iindlela kunye nolawulo oluchanekileyo, luphumeleza ukusetyenziswa kwamandla ngaphandle kokuncama ukusebenza.

- Ngaba inkxaso ekude ifumaneka?Ewe sinikezela ngenkxaso ekude ngemigca yethu yoncedo lobuchwephesha kwaye inokubonelela nge-intanethi ekufumaneni kwi-intanethi njengoko kufuneka.

Imveliso izihloko ezishushu

- Intshayelelo kwimveliso yepaneli ye-EPS

Umzi mveliso uhlala uvela ngetekhnoloji entsha ephuma ephucula ukuveliswa kweephaneli ze-EPS. Umatshini wePolystyrene Colject ngoku ubandakanya i-IOI ukusebenza ngobuchule, esebenzayo ngakumbi. Oku kuxhumanisa oku kuxhaswa yinyani - Ukubeka esweni kwexesha kunye nohlalutyo lwedatha, lunceda iifektri zokuphucula intsebenzo kunye nokunciphisa inkunkuma.

- Ukuzinza kwimveliso yePolystrene

Inkxalabo yokusingqongileyo ejikeleze ukusetyenziswa kwePolystyrene iqhube intsha ukuphinda isebenze kwakhona kunye nophuhliso lwezinto ezibonakalayo. Abavelisi be-polystyrene bajolise ekuveliseni iindlela ezizezinye ze-biodegram kunye nokwandisa iinkqubo zokurisayikilisha. Ezi nzame zibalulekile ekunciphiseni indawo yendawo yokusingqongileyo.

- Impembelelo ye-Automation ngokusebenza ngefektri

Ukuveliswa kwemveliso yePolystyrene kuneengxaki zokuguqula umzi-mveliso, ukuvumela ukungeniswa okuphezulu kunye neendleko zabasebenzi ezisezantsi. Ukuchaneka kunye nokungaguquguqukiswa kwezinkqubo ezizenzekelayo kuphucula umgangatho wemveliso ngelixa kuncitshiswa inkunkuma, eyona nto ibalulekileyo kumashishini okhuphiswano.

- Iimpawu zoKhuseleko eziPhambili kwiLawuni zale mihla

Kunye namatshini we-polystyrene ye-polystyrene, ukhuseleko luphambili oluphezulu. Iindawo zokukhusela eziphuculweyo, ezinje ngeendawo zokuvalwa ezizenzekelayo kunye nokuvalwa okumiselweyo, ncedantela ukuthintela iingozi kunye nokukhusela abasebenzi. Ezi mpawu zibalulekile ekugcineni imeko yomsebenzi okhuselekileyo kwizicwangciso zefektri ezixakekileyo.

- Ukwenza ngokwezifiso kwi-EPS Gamination Mattines

Ibango le-EPS eSebenzayo eSebenzayo iyakhula njengoko iifektri zifuna ukwahlula iimveliso zazo. Itekhnoloji yePolystyrene ngoku ivumela ukungqinelana kwemigaqo yokulungelelaniswa kwemfundo eyahlukileyo, ukubonelela ngezinto zokusebenza ngendlela eyiyo.

- Ixabiso - Ukusebenza kakuhle kwimveliso yePolystyrene

Umatshini ugxile kwizicwangciso zokunciphisa iindleko, ukusuka kumandla - Ukusuka kwimilo esebenzayo ukunciphisa ukusetyenziswa kwezinto eziluhlaza. Olu vuselelo lubalulekile kwimicimbi ejolise ukugcina amaxabiso okhuphiswano ngelixa uqinisekisa phezulu - Iziphumo ezisemgangathweni.

- Imigqaliselo yeHlabathi kwimveliso ye-Polystrene

Imakethi yamanye amazwe yeemveliso ze-polystyrene inda ngokukhawuleza, iifektri ezikhuthaza amandla abo ukuze zifezekise iimfuno zehlabathi. Ukunyuka kwe-polystyrenes

- Imiceli mngeni kwi-polystyrene ibuyisela kwakhona

Ngelixa ukuphinda kusetyenziswe kwakhona licandelo elibalulekileyo lomveliso ozinzileyo, imiceli mngeni iyaqhubeka kwiimveliso ze-EPS ezifanelekileyo. Umatshini we-polystyrene telystyrene telystyrene intsha yokuphucula iindlela zokurisayikilisha, esenza kube lula kwaye kunokwenzeka ngakumbi kwimizi-mveliso yokwamkela i-ECO - Ubuhlobo bokuziphatha.

- Indima yoMatshini yePolystyrene kwi-Preliab

Ukusetyenziswa kweephaneli ze-EPS kulwakhiwo lwangaphambili kuyanyuka, kunye nezixhobo zomatshini wePolystyrene ebonelela ngolungelelwaniso oluyimfuneko lokuvelisa izinto eziphezulu. Le meko ixhasa amaxesha akhawulezileyo amaxesha kunye neendleko zomsebenzi ezincitshisiweyo, zinomdla kubavelisi kunye nabakhi ngokufanayo.

- Ukuphuculwa kokufakwa kweephaneli ze-EPS

Iipaneli ze-EPS zisetyenziswa ngokwakha iipropathi zabo ezilungileyo zokuvala. Uhambo lwePolystyrene

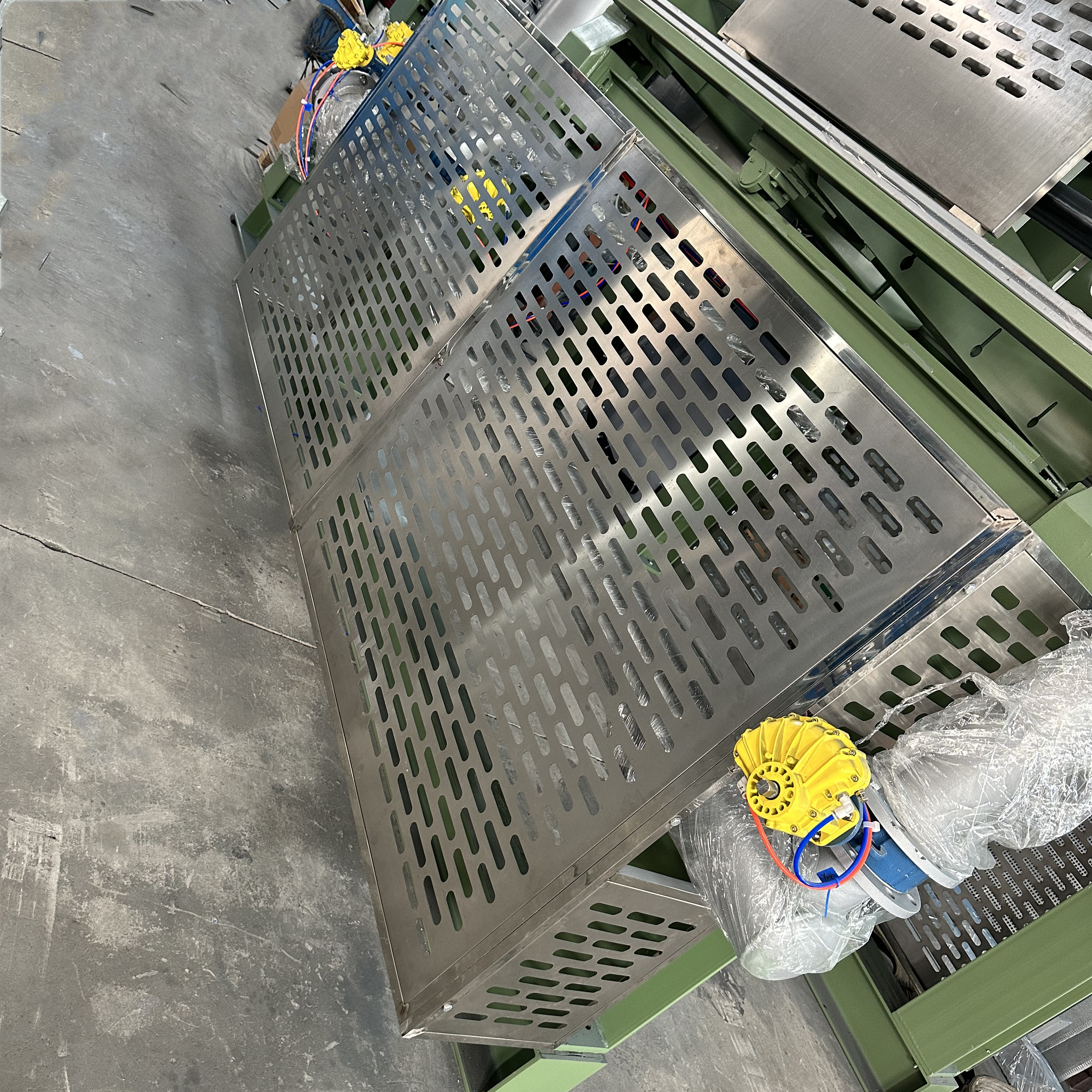

Inkcazo yemifanekiso