Umatshini ophumeleleyo weStyrofoam weStyrofofoa

Iinkcukacha zemveliso

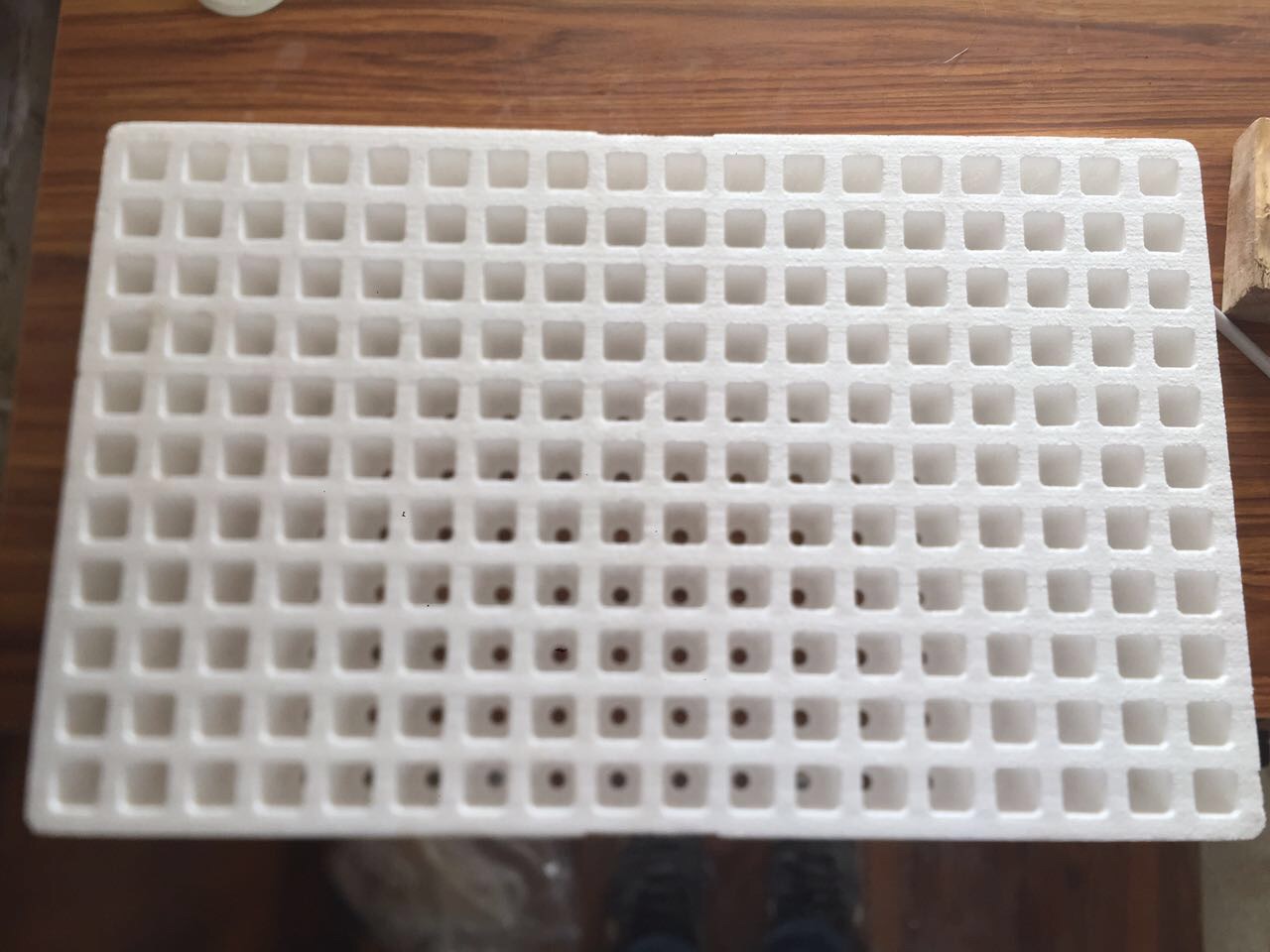

Umatshini wokubumba weStyrofoam wokuBumba okusebenza kakuhle kwebhokisi inenkqubo efanelekileyo ye-vacuum, inkqubo ye-hydraulic ye-hydraulic, kunye nenkqubo yokuqhuba ngokukhawuleza. Kwimveliso efanayo, ixesha lomjikelo ngoomatshini bohlobo lwe-E-25% emfutshane kunakwimishini eqhelekileyo, kwaye ukusetyenziswa kwamandla yi-25%.

Styrofoam shape moulding machine with high efficiency for box completes with PLC, touch screen, filling system, efficient vacuum system, hydraulic system, electric box

Iimpawu eziphambili

Iipleyiti zoomatshini zenziwe ngeepleyiti zentsimbi zentsimbi ukuze zihlale zihleli;

Umatshini unenkqubo efanelekileyo ye-vacuum, itanki ye-vacuum kunye netanki le-conderser yahlulahlula;

Umatshini usebenzisa inkqubo ye-hydraulic, ukugcina ixesha lokuvala kunye nokuvula;

Iindlela ezahlukeneyo zokugcwalisa ziyafumaneka ukunqanda ingxaki yokugcwalisa kwiimveliso ezizodwa;

Umatshini usebenzisa inkqubo enkulu yombhobho, evumela uxinzelelo loxinzelelo olusezantsi. I-3 ~ 4bar steam inokusebenzisa umatshini;

Umatshini woxinzelelo kunye nengcinezelo yokutyikitywa ilawulwa yi-manometer yoxinzelelo lwaseJamani kunye nabalawuli boxinzelelo;

Izinto ezisetyenzisiweyo kumatshini zingeniswa ngokungeniswa ngaphakathi kwaye zidume iimveliso ezidumileyo, ukungasebenzi kakuhle;

Umatshini ngemilenze ephakamisayo, ke umxhasi kufuneka kufuneka enze iqonga lokusebenza labasebenzi.

Iiparamitha eziphambili

| Into | Iyunithi | I-FAV1200E | I-FAV1000E | Fav1600e | Fav1750E | |

| Ubukhulu bomda | mm | I-1200 * 1000 | I-1400 * 1200 | 1600 * 1350 | I-1750 * 1450 | |

| Ubungakanani bemveliso ye-MAX | mm | I-1000 * 800 * 400 | I-1200 * 1000 * 400 | I-1400 * 1150 * 400 | I-1550 * 1250 * 400 | |

| Ukubetha | mm | I-150 ~ 1500 | I-150 ~ 1500 | I-150 ~ 1500 | I-150 ~ 1500 | |

| I-steam | Ukungena | Intshi | 3 '(DN80) | 4 '(DN100) | 4 '(DN100) | 4 '(DN100) |

| Ukuselwa | Kg / umjikelo | 4 ~ 7 | I-5 ~ 9 | I-6 ~ 10 | 6 ~ 11 | |

| Uxinzelelo | Mpa | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Amanzi okupholisa | Ukungena | Intshi | 2.5 '' (DN65) | 3 '(DN80) | 3 '(DN80) | 3 '(DN80) |

| Ukuselwa | Kg / umjikelo | I-25 ~ 80 | 30 ~ 90 | I-35 ~ 100 | I-35 ~ 100 | |

| Uxinzelelo | Mpa | I-0.3 ~ 0.5 | I-0.3 ~ 0.5 | I-0.3 ~ 0.5 | I-0.3 ~ 0.5 | |

| Umoya oxinzelelweyo | Ukungena koxinzelelo oluphantsi | Intshi | 2 '(DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Uxinzelelo olusezantsi | Mpa | I-0.4 | I-0.4 | I-0.4 | I-0.4 | |

| Ukungena okuphezulu | Intshi | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Uxinzelelo oluphezulu | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

| Ukuselwa | m³ / umjikelo | 1.5 | 1.8 | 1.9 | 2 | |

| Amanzi | Intshi | 5 '(DN125) | 6 '(DN150) | 6 '(DN150) | 6 '(DN150) | |

| Umthamo1kg / m³ | S | I-60 ~ 110 | I-60 ~ 120 | I-60 ~ 120 | I-60 ~ 120 | |

| Qhagamshela umthwalo / amandla | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Ubukhulu becala (l * w * h) | mm | I-4700 * 2000 * 4660 | I-4700 * 2250 * 4660 | 4800 * 2530 * 4690 | I-5080 * 2880 * 4790 | |

| Ubunzima | Kg | I-5500 | I-6000 | I-6500 | I-7000 | |

Ityala

Ividiyo ehambelana nayo

The machine's fast hydraulic system enables seamless operation, reducing manual effort while augmenting productivity. Further, its quick drainage system ensures that the machine maintains its efficiency levels, ultimately improving the overall production rate. By integrating the Styrofoam Melting Machine into your manufacturing line, you can leverage the benefits of a high-performance, energy-efficient and cost-effective solution for your Styrofoam moulding needs. At Dongshen, we understand the importance of efficiency and reliability in manufacturing processes. Our Styrofoam Melting Machine offers you a solution that combines these essentials, empowering your business to deliver superior quality while enhancing production efficiency.