Yuqori uchun yuqori darajadagi STYROFAME SHYFING MAKTABI

Mahsulot tafsilotlari

Styrofom shakli shaklini quti uchun yuqori samaradorligi bilan bo'shliqning samarali tizimi, tezkor gidravlik va tez drenajlash tizimiga ega. Xuddi shu mahsulot uchun E turidagi tsikl vaqti oddiy mashinada, energiya iste'moli 25% dan yuqori va energiya sarfi katta.

Styrofoam shakli shakllantirish mashinasi plc bilan yuqori samaraliroq, sensorli ekran, to'ldirish tizimi, samarali vakuum, gidravlik tizim, elektr qutisi

Asosiy xususiyatlar

Mashinalar plitalari qalin po'lat plitalardan yasalgan, shuning uchun u uzoq davom etmoqda;

Mashina samarali vakuum tizimiga ega, vakuum va kondensator alohida;

Mashina tezkor gidrotexnika tizimidan foydalanadi, mog'or yopilish va ochilish vaqtini tejash;

Maxsus mahsulotlardagi muammolarni to'ldirishning oldini olish uchun turli xil to'ldirish usullari mavjud;

Mashina katta bosimni pastda bug'lash uchun katta quvur tizimidan foydalanadi. 3 ~ 4bar bug 'mashinani ishlata oladi;

Mashinaning bug 'bosimi va pirogli bug'da o'stirish nemis bosimi va bosimni tartibga soluvchilar tomonidan boshqariladi;

Mashinada ishlatiladigan komponentlar asosan import va taniqli markali mahsulotlar, past nosozlik;

Oyoqlarni ko'taradigan mashina, shuning uchun mijoz faqat ishchilar uchun oddiy ishlaydigan platformaga ega bo'lishi kerak.

Asosiy texnik parametrlar

| Buyum | Birlik | Fav1200e | Fav1400e | Fav1600e | Fav1750e | |

| Mog'or o'lchami | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 | |

| MAX Mahsulot o'lchovi | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 | |

| Insult | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Bug ' | Kirish | Dyuym | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Iste'moli | Kg / tsikl | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Bosim | Mpa | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Sovuq suvi | Kirish | Dyuym | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Iste'moli | Kg / tsikl | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Bosim | Mpa | 0,3 ~ 0.5 | 0,3 ~ 0.5 | 0,3 ~ 0.5 | 0,3 ~ 0.5 | |

| Siqilgan havo | Past bosimning kamligi | Dyuym | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Past bosim | Mpa | 0,4 | 0,4 | 0,4 | 0,4 | |

| Yuqori bosimli kirish | Dyuym | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Yuqori bosim | Mpa | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | 0,6 ~ 0.8 | |

| Iste'moli | M³ / tsikl | 1.5 | 1.8 | 1.9 | 2 | |

| Drenaj | Dyuym | 5 '' (DN125) | 6 '' (dn150) | 6 '' (dn150) | 6 '' (dn150) | |

| Salim salohiyati15 kg / m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Yuklash / quvvatni ulang | Kw | 9 | 12.5 | 14.5 | 16.5.5 | |

| Umumiy o'lcham (l * w * h) | mm | 4700 * 2000 * 4660 | 4700 * 2250 * 4660 | 4800 * 2530 * 4690 | 5080 * 2880 * 4790 | |

| Vazn | Kg | 5500 | 6000 | 6500 | 7000 7000 | |

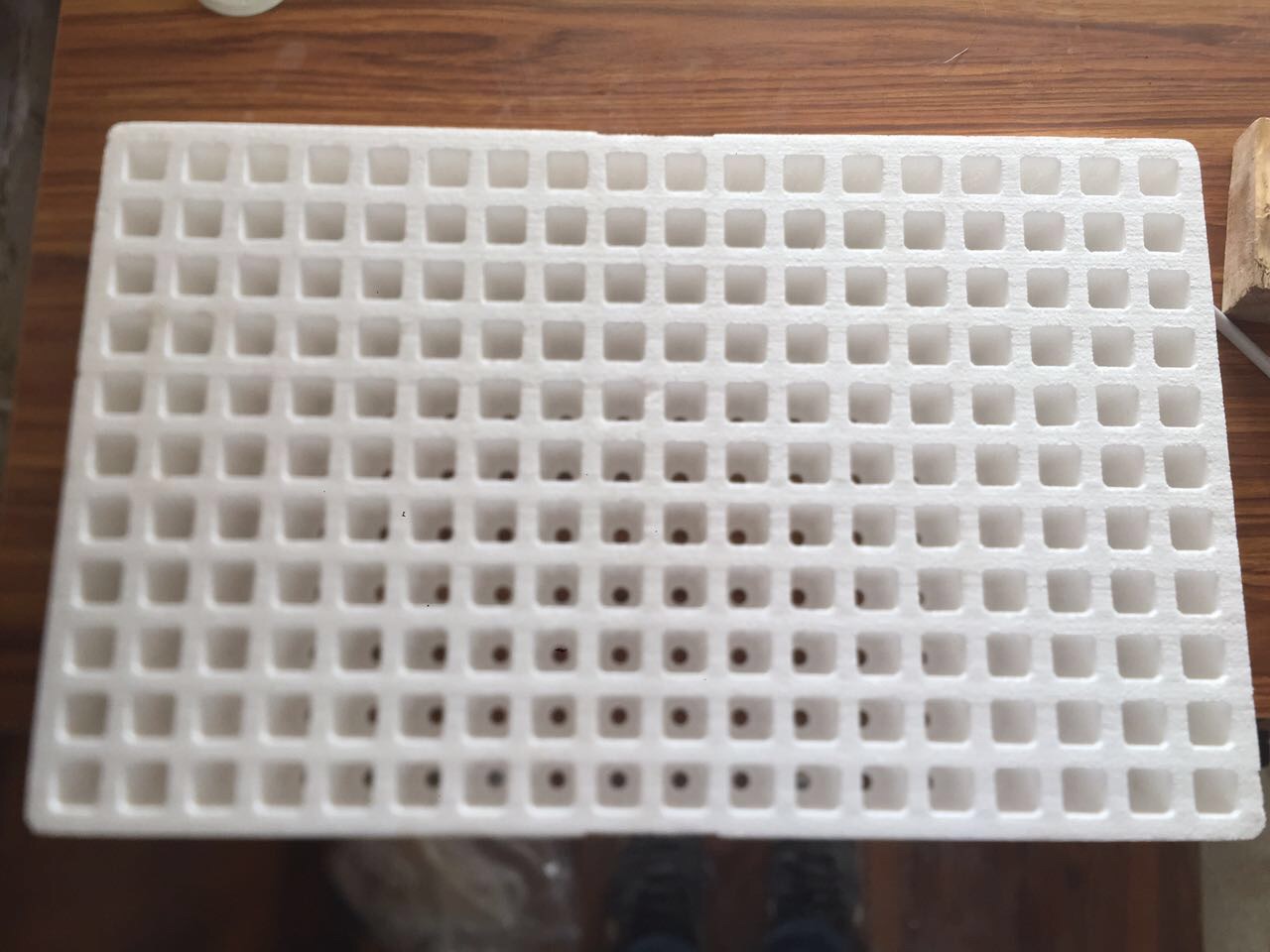

Ish

Tegishli video

The machine's fast hydraulic system enables seamless operation, reducing manual effort while augmenting productivity. Further, its quick drainage system ensures that the machine maintains its efficiency levels, ultimately improving the overall production rate. By integrating the Styrofoam Melting Machine into your manufacturing line, you can leverage the benefits of a high-performance, energy-efficient and cost-effective solution for your Styrofoam moulding needs. At Dongshen, we understand the importance of efficiency and reliability in manufacturing processes. Our Styrofoam Melting Machine offers you a solution that combines these essentials, empowering your business to deliver superior quality while enhancing production efficiency.