Juu - Utendaji wa EPS Pelletizer: Suluhisho la kutengeneza sahani ya thermocol

Maelezo ya bidhaa

Mashine ya kutengeneza sahani ya Thermocol hutumiwa kutengeneza vizuizi vya EPS, kisha kukatwa kwa shuka kwa insulation ya nyumba au kupakia. Bidhaa maarufu zilizotengenezwa kutoka kwa shuka za EPS ni paneli za sandwich za EPS, paneli za 3D, paneli za ndani na za nje za ukuta, upakiaji wa glasi, ufungaji wa fanicha nk.

Mashine ya kutengeneza sahani ya Thermocol inafaa kwa ombi ndogo ya uwezo na uzalishaji mdogo wa vizuizi, ni mashine ya kiuchumi ya EPS. Na teknolojia maalum, mashine yetu ya kutengeneza sahani ya thermocol inaweza kutengeneza vizuizi vya wiani wa 4g/L, block ni sawa na ya ubora mzuri.

Mashine inakamilisha na mwili kuu, sanduku la kudhibiti, blower, mfumo wa uzani nk.

Vipengele kuu

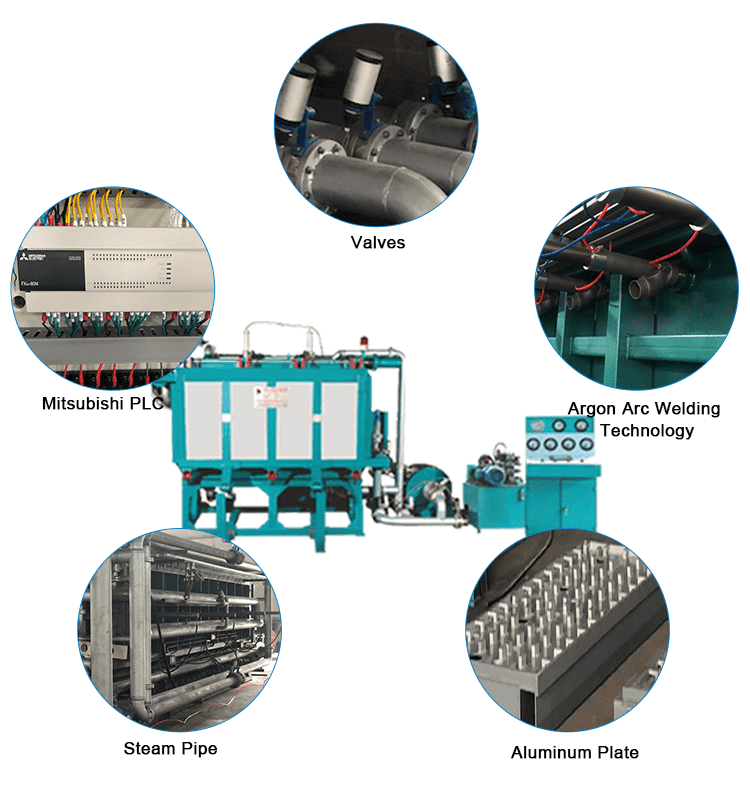

1. Mashine inachukua Mitsubishi Plc na skrini ya kugusa ya Winview kwa ufunguzi wa moja kwa moja, kufunga kwa ukungu, kujaza nyenzo, kukausha, utunzaji wa joto, baridi ya hewa, kupungua na kuachana.

2. Paneli zote sita za Mashine ni kupitia matibabu ya joto ili kutolewa mafadhaiko ya kulehemu, ili paneli haziwezi kuharibika chini ya joto la juu;

3. Cavity ya Mold imetengenezwa na sahani maalum ya aloi ya alumini na kiwango cha juu - ufanisi wa joto, unene wa sahani ya alumini 5mm, na mipako ya Teflon kwa kupungua rahisi.

4. Mashine imeweka kiwango cha juu - shinikizo kwa nyenzo za kunyonya. Baridi hufanywa na hewa ya convection na blower.

5. Sahani za mashine ni kutoka kwa hali ya juu - ya ubora wa chuma, kupitia matibabu ya joto, nguvu na hakuna mabadiliko.

6. Kutengwa kunadhibitiwa na pampu ya majimaji, kwa hivyo ejectors zote zinasukuma na kurudi kwa kasi sawa;

Vigezo kuu vya kiufundi

Bidhaa | Sehemu | PB2000A | PB3000A | PB4000A | PB6000A | |

Ukubwa wa cavity | mm | 2040*1240*630 | 3060*1240*630 | 4080*1240*630 | 6100*1240*630 | |

Saizi ya kuzuia | mm | 2000*1200*600 | 3000*1200*600 | 4000*1200*600 | 6000*1200*600 | |

Mvuke | Kiingilio | Inchi | DN80 | DN80 | DN100 | DN150 |

| Matumizi | Kilo/mzunguko | 18 ~ 25 | 25 ~ 35 | 40 ~ 50 | 55 ~ 65 |

| Shinikizo | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Hewa iliyoshinikizwa | Kiingilio | Inchi | DN40 | DN40 | DN50 | DN50 |

| Matumizi | m³/mzunguko | 1 ~ 1.2 | 1.2 ~ 1.6 | 1.6 ~ 2 | 2 ~ 2.2 |

| Shinikizo | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 |

Mifereji ya maji | Steam vent | Inchi | DN100 | DN150 | DN150 | DN150 |

Uwezo 15kg/m³ | Min/mzunguko | 4 | 5 | 7 | 8 | |

Unganisha mzigo/nguvu | Kw | 6 | 8 | 9.5 | 9.5 | |

Mwelekeo wa jumla (L*H*W) | mm | 3800*2000*2100 | 5100*2300*2100 | 6100*2300*2200 | 8200*2500*3100 | |

Uzani | Kg | 3500 | 5000 | 6500 | 9000 | |

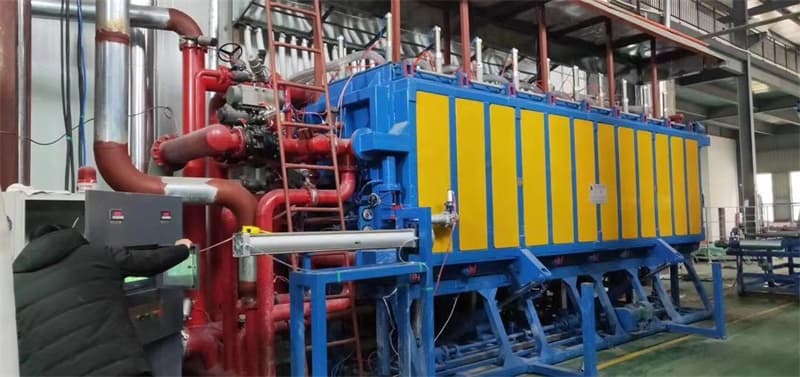

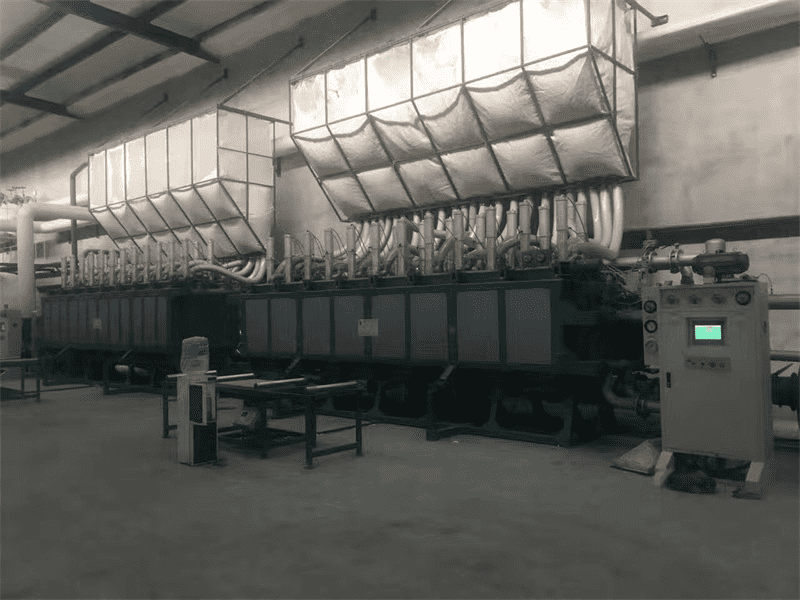

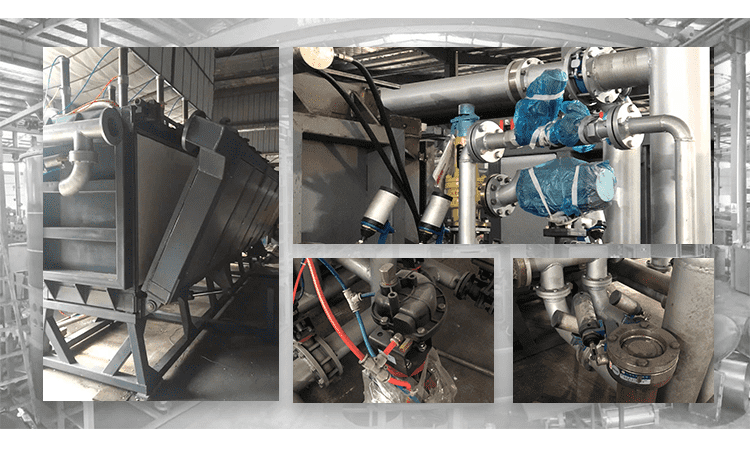

Kesi

Video inayohusiana

By choosing our EPS Pelletizer, you're selecting a machine that has undergone rigorous testing to ensure it meets the highest industry standards. What’s more, Dongshen is committed to providing comprehensive customer support, ensuring that your Thermocol Plate Making Machine operates at its full potential for the long-term. Optimize your insulation and packing needs by incorporating our state-of-the-art EPS Pelletizer. This machine offers a seamless and efficient process, guaranteed to save time and increase productivity. With the EPS Pelletizer, you can exceed industry standards and achieve unparalleled results. Experience the epitome of performance, efficiency, and reliability, only with Dongshen's EPS Pelletizer.