Juu - ufanisi wa umeme wa waya moto wa cutter - Mashine ya ukingo wa Polystyrene

Maelezo ya bidhaa

Mashine ya ukingo wa Polystyrene na utupu ni mashine bora ya EPS kutengeneza vizuizi vya EPS. Vitalu vya EPS vinaweza kukatwa kwa shuka kwa insulation ya nyumba au kufunga. Bidhaa maarufu zilizotengenezwa kutoka kwa shuka za EPS ni paneli za sandwich za EPS, paneli za 3D, paneli za ndani na za nje za ukuta, upakiaji wa glasi, ufungaji wa fanicha nk.

Mashine ya ukingo wa kuzuia polystyrene na utupu inaweza kutoa vizuizi vya juu vya EPS, kufanya kazi kwa mzunguko wa haraka, na vitalu vyote ni sawa na nguvu na kwa unyevu wa chini wa maji. Mashine inaweza pia kufanya vizuizi vya chini vya wiani na ubora mzuri. Inaweza kufanya wiani mkubwa kwa 40g/L na wiani wa chini kwa 4g/L.

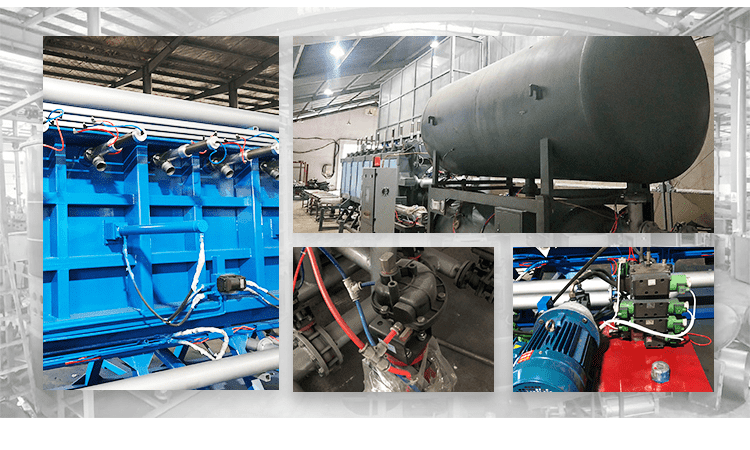

Mashine ya ukingo wa kuzuia polystyrene na utupu kamili na mwili kuu wa mashine, sanduku la kudhibiti, mfumo wa utupu, mfumo wa uzani nk.

Mashine ya ukingo wa kuzuia polystyrene na faida za utupu:

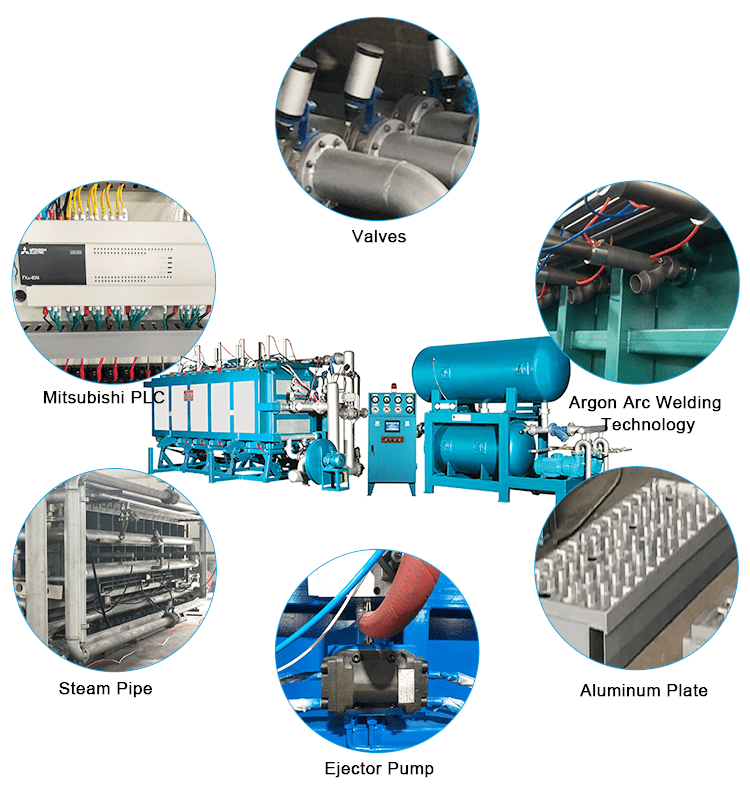

1.Machine imetengenezwa kwa mirija ya mraba ya juu - nguvu na sahani nene za chuma;

2.Machine hutumia sahani za mvuke za alumini 5mm na mipako ya Teflon. Na chini ya sahani ya alumini, msaada mkubwa wa ukubwa kwa idadi kubwa huwekwa ili kuzuia kuharibika kwa sahani ya alumini chini ya shinikizo kubwa. Sahani za alumini haina't mabadiliko ya fomu baada ya miaka kumi kufanya kazi;

3.Machine'Paneli zote sita ni kupitia matibabu ya joto ili kutolewa mkazo wa kulehemu, ili paneli haziwezi kuharibika chini ya joto la juu;

4.Machine iliyo na mistari zaidi ya mvuke ili kuhakikisha kuwa inaangazia hata kwenye vizuizi, kwa hivyo fusion ya kuzuia ni bora;

Sahani za 5.Machine ziko na mfumo bora wa mifereji ya maji kwa hivyo vizuizi vimekaushwa zaidi na vinaweza kukatwa kwa muda mfupi;

6. Sahani zote za mashine kupitia kuondoa kutu, kunyunyizia mpira, kisha fanya uchoraji wa msingi wa kutu na uchoraji wa uso, kwa hivyo mwili wa mashine sio rahisi kupata kutu;

7.Machine Tumia mfumo wa bomba la smart na mchakato wa kunyoa, kuhakikisha kuwa mchanganyiko mzuri wa vitalu kwa wiani mkubwa na wiani wa chini;

8.Mfumo wa kujaza na mfumo mzuri wa utupu huhakikisha mashine inafanya kazi haraka, kila block 4 ~ dakika 8;

9.

Vipengele 10. Vipengee vinavyotumiwa kwenye mashine ni bidhaa zilizoingizwa au maarufu.

Vigezo kuu vya kiufundi

Bidhaa | Sehemu | PB2000V | PB3000V | PB4000V | PB6000V | |

Ukubwa wa cavity | mm | 2040*1240*1030 | 3060*1240*1030 | 4080*1240*1030 | 6100*1240*1030 | |

Saizi ya kuzuia | mm | 2000*1200*1000 | 3000*1200*1000 | 4000*1200*1000 | 6000*1200*1000 | |

Mvuke | Kiingilio | Inchi | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Matumizi | Kilo/mzunguko | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Shinikizo | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Hewa iliyoshinikizwa | Kiingilio | Inchi | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Matumizi | m³/mzunguko | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Shinikizo | MPA | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Maji baridi ya utupu | Kiingilio | Inchi | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Matumizi | m³/mzunguko | 0.4 | 0.6 | 0.8 | 1 | |

Shinikizo | MPA | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Mifereji ya maji | Utupu | Inchi | 4 '' (DN100) | 5 '' (DN125) | 5 '' (DN125) | 6 '' (DN150) |

Chini ya mvuke | Inchi | 4 '' (DN100) | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Hewa baridi vent | Inchi | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Uwezo 15kg/m³ | Min/mzunguko | 4 | 5 | 7 | 8 | |

Unganisha mzigo/nguvu | Kw | 19.75 | 23.75 | 24.5 | 32.25 | |

Mwelekeo wa jumla (L*H*W) | mm | 5700*4000*2800 | 7200*4500*3000 | 11000*4500*3000 | 12600*4500*3100 | |

Uzani | Kg | 5000 | 6500 | 10000 | 14000 | |

Kesi

Video inayohusiana

Our technical team is committed to supporting you in mastering the functionality of the Electric Hot Wire Foam Cutter. We provide comprehensive training and post-purchase support to assist you in harnessing the full potential of this versatile machine. Invest in the future of EPS block moulding with the Electric Hot Wire Foam Cutter from Dongshen, a machine that embodies innovation, efficiency, and performance like none other in the market. Revolutionize your EPS manufacturing process with the advanced technology of our Polystyrene Block Moulding Machine. Experience the Dongshen difference today.