Mesin Panel 3D Aovatif pikeun prosés corking.

Rincian produk

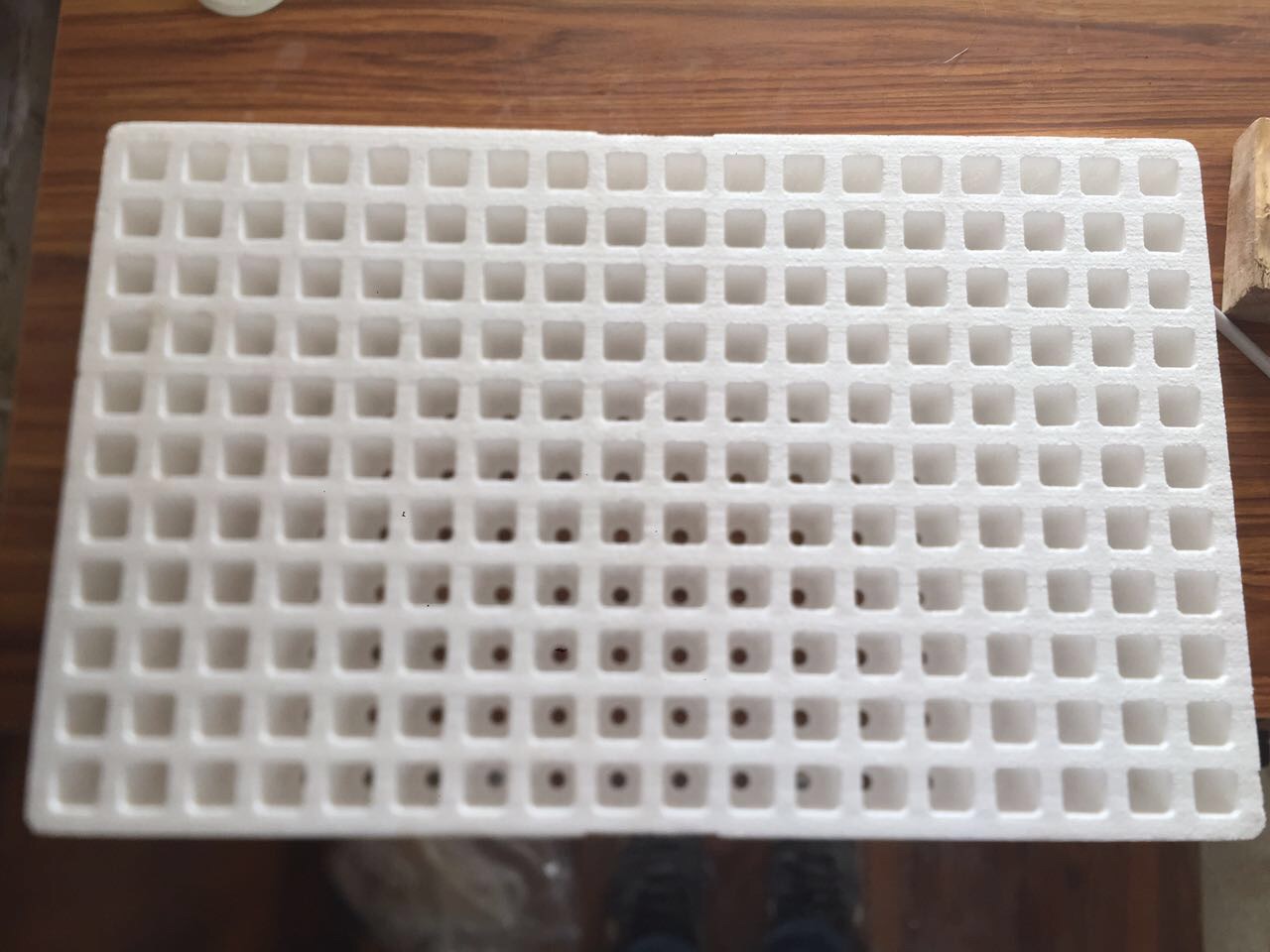

Mesin Char Worring Stilling More sareng vakum ieu dipaké babarengan sareng cricing produk bungkusan sapertos bungkusan sareng kotak listrik, baki tiasa ngahasilkeun bentuk jégr. sareng clows jogit sareng ICF.

Ketik firus ngahijikeun Meunteu Gaging Meuntas Khimpuran penting, sistem caurik gancang, sareng sistem saluran gancang. Pikeun produk anu sami, pekténsi waktos dina e kipet mesin 25% langkung pondok tibatan mesin normal, sareng perusahaan énergi kirang 25% kirang 25% kirang.

Mesin réngsé nganggo layar toél, sistem ngeusian, sistem varum efisien, sistem hidrolik, kotak listrik

Fav1200E - 1750E Mesin Styyrofoam Mesin Breyrofoam nganggo vakum (efisiensi luhur)

Fitur utama

1men 1Machine dijieun tina piring baja anu langkung kandel supados tetep panjang;

2.Machine gaduh sistem ventakatif vertity, tank vakum sareng jenser tangki,

3.machine nganggo sistem hidrauric gancang, ngahemat mask panutup sareng muka waktos;

4. Naon waé cara ngeusian anu sayogi pikeun nyegah ngeusian masalah dina produk khusus;

5.Machine kagun sistem pipa bentang, ngamungkinkeun cushing tekanan handap. 3 ~ uap uap tiasa damel mesin;

6.Machine tekanan uap sareng capinging peneteran dikawasa ku Tekolah Tekanan Jerometer sareng Regulator Verman;

7.componén dianggo dina mesin anu paling diimpor sareng produk branded anu terkenal, kalolobaanana

8.Machine kalayan suku angkat, janten klien ngan ukur kedah ngadamel platform anu mestic anu gampang pikeun pagawé.

Parameter Téknis utama

| Barang | Satuan | Fav1200e | Fav1400E | Fav1600e | Fav1750E | |

| Diménsi kapang | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 | |

| Diménsi produk | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 | |

| Sterok | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Uap | Asupna | Tatch | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Konsumsi | Kg / siklus | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 | |

| Tekenan | MPa | 0,4 ~ 0,6 | 0,4 ~ 0,6 | 0,4 ~ 0,6 | 0,4 ~ 0,6 | |

| Cai pendingin | Asupna | Tatch | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Konsumsi | Kg / siklus | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Tekenan | MPa | 0,3 ~ 0,5 | 0,3 ~ 0,5 | 0,3 ~ 0,5 | 0,3 ~ 0,5 | |

| Hawa anu dikomprés | Éntri tekanan rendah | Tatch | 2 '(DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Tekanan rendah | MPa | 0,4 | 0,4 | 0,4 | 0,4 | |

| Éntri tekanan luhur | Tatch | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Tekenan luhur | MPa | 0.6 ~ 0,8 | 0.6 ~ 0,8 | 0.6 ~ 0,8 | 0.6 ~ 0,8 | |

| Konsumsi | m³ / siklus | 1,5 | 1,8 | 1,9 | 2 | |

| Lemes | Tatch | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Kapasitas15kg / m³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Sambungkeun beban / kakawasaan | Kw | 9 | 12,5 | 14,5 | 16,5 | |

| Diménsi umum (l * w * h) | mm | 4700 * 2000 * 4660 | 4700 * 2250 * 4660 | 4800 * 2530 * 4690 | 5080 * 2880 * 4790 | |

| Beurat | Kg | 5500 | 6000 | 6500 | 7000 | |

Pasualan

Paké tagihan

With countless successful installations and satisfied customers, our Automatic Styrofoam Shape Molding Machine stands as a testament to Dongshen's commitment to providing industry-leading machinery and superior customer service. Our team of experts is readily available to assist with installation, training, and after-sale support, ensuring a smooth transition and optimal utilization of your new 3D Panel Machine. Invest in Dongshen's Automatic Styrofoam Shape Molding Machine today, leverage the benefits of advanced technology, and take your production process to the next level. Trust in our machinery to deliver outstanding results and dramatically increase your return on investment. Experience the Dongshen difference with our 3D Panel Machine today!