Hlakol eps Mold Eps bakeng sa lebokose la litlhapi

Litekanyetso tsa sehlooho tsa sehlahisoa

| Mokotla oa Steam | 1200 * 1000mm, 1400 * 1200mm, 1600 * 1350mm, 1750 * 1450mm |

|---|---|

| Boholo Mol | 1120 * 920mm, 1320 * 1120mm, 1520 * 1270mm, 1670 * 1370 |

| Ho etsa lintho | Wood kapa Pu ke CNC |

| Hochinga | CNC ka botlalo |

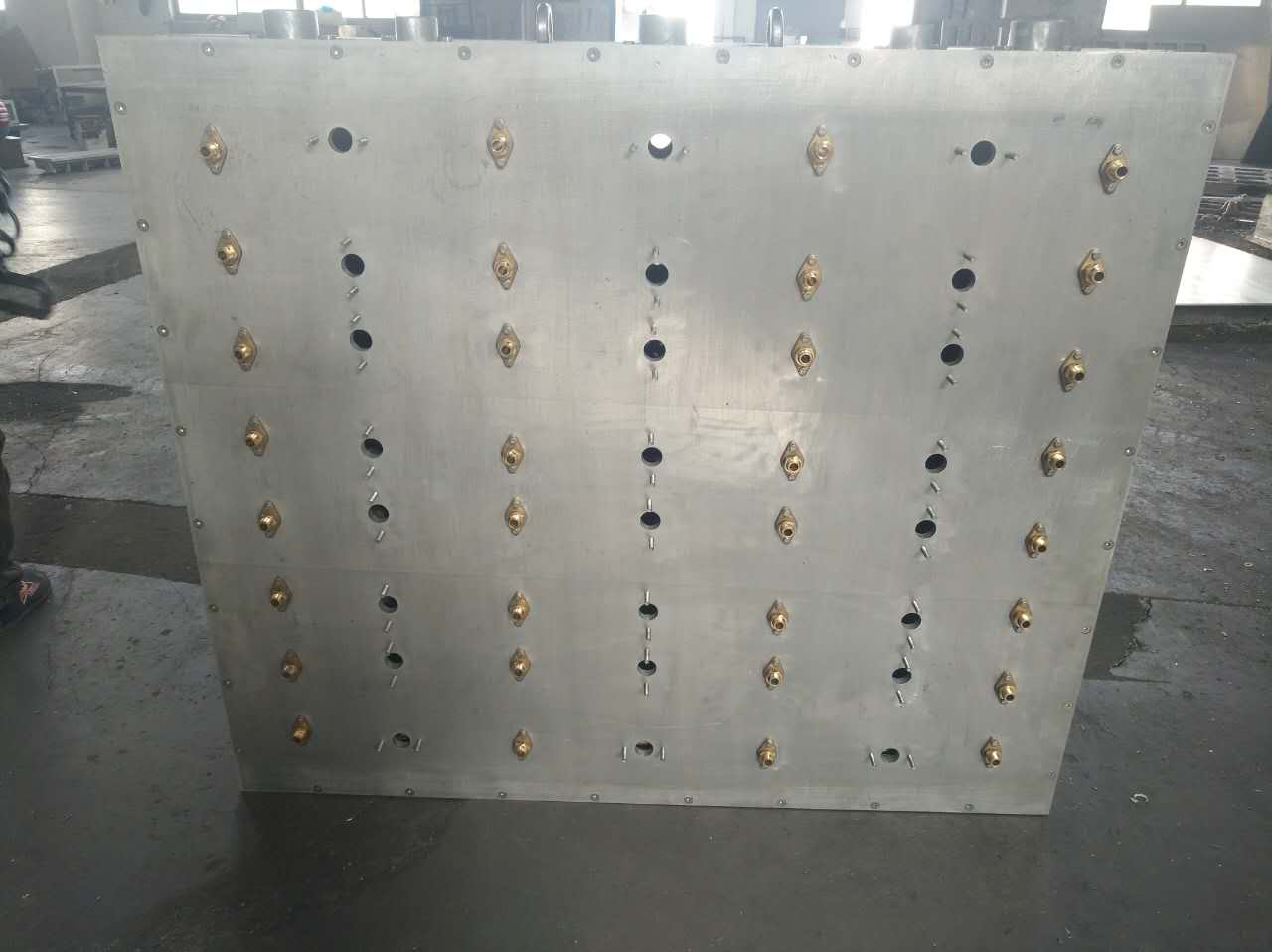

| Aluminium plate botenya | 15mmm |

| Packing | Lebokose la Plywood |

| Nako ea thomello | Matsatsi a 25 ~ 40 |

Litlhaloso tse tloaelehileng tsa lihlahisoa

| Lintho tse bonahalang | Phahameng - Aluminum ea boleng |

|---|---|

| Ho mamella | Nakong ea 1mm |

| Koae | Teflon bakeng sa ho shoeloa habonolo |

Ts'ebetso ea lihlahisoa tsa sehlahisoa

Ho hlahisoa ha eps hlobo e kenyelletsa boenjiniere bo qaqileng le ts'ebetso ea moralo. Qalong, sehlahisoa se lakatsehang se netefatsoa mme se etselitsoe ho sebelisa software ea CD ho netefatsa ho nepahala ho sa tsotelleng. Lintho tsa bohlokoa tse kang litefiso tsa ho phalla le ho pholile lia nkuoa nakong ea phasejeng ea moralo. Ha moralo o phethetsoe, mechini ea CNC e theha hlobo ho tloha PER PROP - Lithibelo tsa Bolubu tsa Aluminum, li bonts'a ho nepahala. Kamora mosehla, hlobo e bokane mme e lekoa ka thata, nyeoe e ntseng e eketseha e matha ea ho netefatsa hore ba kopana le maemo a indasteri. Ts'ebetso tsena li tiisa hore hlobo li tšoarella, e sebetsa hantle ebile e khona ho hlahisa lihlahisoa tsa eps tse precise tse hlakileng.

Maemo a Kopo ea Sehlahisoa

Li-EPS tsa mafura ha li feto-fetoha ebile li sebelisoa hohle indastering e fapaneng. Kaho, e bohlokoa bakeng sa ho hlahisa likhansele tsa insulation le konkreite tse etsang konkreite. Indasteri ea liphutheloana e itšetleha ka lisebelisoa tse sirelletsang, tsa bohlokoa bakeng sa lisebelisoa tsa ho sireletsa lisebelisoa tsa elektroniki le thepa e 'ngoe e bolotsana. Lihlahisoa tsa bareki, hlobo e sebelisoa ho hlahisa lintho tse kang li-coolers le thepa e bobebe ea lihlahisoa. Boikhohomoso ba bona le ketsahalo ea bona li etsa hore ba tsebe ho qoba likarolo tsena, ba bapala karolo ea bohlokoa ho netefatsa boleng ba sehlahisoa le botsitso.

Sehlahisoa kamora - Tšebeletso ea thekiso

Re etsa hore litšebeletso tse felletseng, li fana ka tšehetso e felletseng, ho fana ka lits'ebeletso tsa ho lokisa le ho lokisa. Mahlale a rona ba nang le boiphihlelo a fumaneha ho rarolla bothata le ho fana ka tataiso ea botekgeniki. Re boetse re fana ka nako ea waranti nakong eo sehlopha sa rona se tla thusa ho sebetsana le liphiri leha e le life tsa tlhahiso ea lihlahisoa hanghang.

Tsamaiso ea Lihlahisoa

Li-EPS tsa li-eps li tletse ka mabokose a plywood ho netefatsa lipalangoang tse bolokehileng. Re sebelisana 'moho le balekane ba nang le ts'ehetso ea thepa ho netefatsa nako le tšenyo - ho tsamaisoa ha mahala, ho fana ka tlhaiso-leseling bakeng sa maemo a hau a bonolo.

Melemo ea sehlahisoa

- Price e phahameng ka lebaka la cnc mochini oa cnc

- E tšoarelle, e entsoe ho tloha qalong - Aluminium ea sehlopha

- Li-cheke tsa boleng bo potlakileng

- E etselitsoe ke litsebi tsa indasteri tse nang le boiphihlelo ba lilemo tse fetang tse 20

FAQ ea sehlahisoa

- Q1: Ke boitsebiso bofe bo sebelisetsoang linatsi tsa eps?

A1: Re sebelisa PER - Nlaole ea boleng ba Aluminum ho ea bohlanya meqolo ea rona, ho bolela hore o tla tšoarella le ho tšoarella le nako e telele. Litšolo tsa rona li etselitsoe ho mamella mathata a ho sebelisa khafetsa, a li etsa hore li lokeloe ke likopo tse fapaneng tsa indasteri. - Q2: Li-Molds tsa litsu li entsoe ka nepo?

A2: Eps ea rona e sebetsa ka botlalo ho sebelisa mechini ea CNC, ho fihlela mamello ho 1mm. Morero ona o tiisa hore lihlahisoa tsa li-EPS tsa ho qetela li kopana le litlhaloso tse tobileng le litekanyetso tsa boleng bo hlokahalang ke indastering e fapaneng. - Q3: Na boima ba li blis ba ka lekenoe ho latela litlhoko tse itseng?

A3: E, joalo ka moetsi oa Mold Eps, Re ka Rala Batho ba Bolulo ba Thibelo ho ea fihlela litlhoko tse ikhethang tsa moreki. Baenjiniere ba rona ba nang le boiphihlelo ba fetola sampole ea bareki hore e be lintlha tse qaqileng kapa meralo ea 3D ka tlhahiso e tsamaeang. - Q4: Nako ea thomello e hakanyetsoang ea mafura ke efe?

A4: Nako ea ho fana ka matsatsi a 25 ho isa ho 40, ho latela ho rarahana ha boqapi le sekala sa tlhahiso. Re loanela ho kopana le li-cluences tse ngata ka nepo. - Q5: Na mehloli ea hau e lumellana le metjeko ea eps ho tsoa linaheng tse fapaneng?

A5: E, re na le boiphihlelo bo bongata haholo bakeng sa seretse se tloaelehileng sa Se-China, Sejeremane, Korea le metjeko ea eps. - Q6: Mokhoa oa ho paka oa hlobotseng eps

A6: Re paka lithane tsa rona ka mabokoseng a rona a pherese ho li sireletsa nakong ea maeto. Mokhoa ona o sirelletsoa khahlanong le tšenyo, o netefatsa hore o tla be o sireletsehile sebakeng sa hau. - Q7: Na u fana ka 'nete ea' nete ho eps linko?

A7: E, re fana ka nako ea 'nete eo re e koahelang le eona lekhalo la thepa le e koahelang. Rona kamora - Sehlopha sa litšebeletso sa thekiso se fumaneha bakeng sa tokiso kapa tšehetso efe kapa efe e hlokahalang. - Q8: U etsa bonnete ba hore boleng ba li b eps tsa hau tsa eps

A8: Mehato ea rona ea taolo ea boleng ba boleng ba boleng bo akaretsang, e koahela sethala se seng le se seng ho tloha ho tloha patineng, ho lata, ho bokella mechining. Motso o mong le o mong o potlakela ho hlahlojoa o sa fetoheng - Q9: Na o ka thusa ho itlopanya setup e ncha ea fektheri?

A9: E, sehlopha sa theknoloji ea rona ea nang le boiphihlelo se ka thusa ho qapa likutula tse ncha tsa fektheri, li fana ka phetoho e felletseng - Litharollo tsa Bohlokoa tsa ho ntlafatsa ts'ebetso ea tlhahiso le bokhoni ba tlhahiso. - Q10: Ke litebello tsa tikoloho tsa tikoloho ke eng bakeng sa eps Mold

A10: Re ikemiselitse ho sebelisa lisebelisoa tse nchafalitsoeng le ho ntlafatsa katleho ea matla lits'ebetsong tsa rona ho fokotsa maemo a tikoloho a ntse a boloka melao ea tikoloho.

Lihlooho tse chesang tsa sehlahisoa

- Mokhoa oa ho tsepamisa maikutlo o ntlafatsa ho etsa tlhahiso ea mold

Khokahano ea mechini ea CNC ho EPS Mold Ho etsa lintho ka mokhoa o hlakileng ho etsahala le ka katleho. Mechini e nang le CN e lumella taolo e nepahetseng ka ts'ebetso ea sebōpo sa phepo ea sebōpeho sa pōpo ebe e netefatsa hore Mold Masedires a le masene a le thata, ka tloaelo 1mm. Ho nepahala lena ho bohlokoa bakeng sa ho hlahisa lihlahisoa tse rarahaneng tsa eps tse hlokang boholo le boleng. Matsoho a khalefalitsoeng a Mechine ea CNC e ntse e potlakisa makhetlo a mangata, e bolela ho nehelana ka potlako ntle le ho sekisetsa boleng. Joalokaha moetsi oa Mol ea Mold Eps, ho lokisa CNCration Conciing ho boloka tokiso ea tlholisano le ho kopana le balekane ba bareki ba libakeng tse fapaneng tsa khoebo.

- Karolo ea Aluminium ka eps ea eps ea ho tšoarella

Aluminium ke thepa e khethiloeng ho tlhahiso ea li-eps mushs ka lebaka la ho tšoarella ha eona le thepa e bobebe. Ho tšeloa ha eona khaello le ho hanyetsa moleko ho etsa hore e be le mokhoa oa ho futhumatsa o futhumatsang o futhumatsang o futhumatsang mocheso le ho futhumatsa tlhahiso nakong ea tlhahiso. Ntle le moo, ho bonolo ho sebetsana le litšenyehelo tsa basebetsi le ho ntlafatsa ts'ebetso ea ts'ebetso. Joalokaha moetsi oa Mol ea Mold Eps, o sebelisa Aluminium ea boleng ba rona - Ho feta moo, mokhoa o khothatsang oa aluminium o sebetsana le mekhoa e tsitsitseng, ho sebetsana le matšoenyeho a tikoloho a ntseng a hola.

- Ho tsitsipana 'moho ho eps Mold Eps

Ka ho hlahlobisisa litlhaso tse ntseng li eketseha mabapi le litšusumetso tsa tikoloho, baetsi ba Moleng ba EPes ba nkhabisa ho latela mekhoa e tsitsitseng. Sena se kenyelletsa ho sebelisa lisebelisoa tse sebelisang bocha ka tlhahiso ea hlobo le ho tsetela ho ea ho ea matla - Mechini e sebetsang ho fokotsa mehato ea maoto a mapolanka. Ntle le moo, ho theha mekhoa e meng e metle ea biodegradation ho lihlahisoa tsa setso tsa EPS li ntse li eketseha. Boiteko bo joalo ha bo senyehe feela empa bo kopa feela eco - bareki ba tsebahalang, ba netefatsa litefo lipakeng tsa boikarabelo ba indasteri le boikarabello ba tlhaho. E le moetsi oa setsebi sa hlobo eps, re lula re ikemiselitse liketsong tsena, re thusa ho bula tsela ea bokamoso bo botala.

- Lits'ebeletso tsa tloaelo ea EPS: Ho kopana le litlhoko tsa khoebo

Bokhoni ba ho etsa limmapa tsa tloaelo ea ho etsa limmapa tse bohlokoa ho sebetsana le litlhoko tse ikhethileng tsa indasteri e fapaneng. Ho tloha kahong ho ea thepa ea bareki, lekala ka leng le hlokang ho ba le boqapi ba bolileng. Tloaelo e kenyelletsa ho fetola sampole ea bareki ho fetola sampole ea bareki ka mokhoa o hlakileng kapa mefuta ea 3D, e netefatsa hore hlobo e 'ngoe le e' ngoe e kenyeletsa litlhaloso tsohle. Bophahamo ba bokhoni bo ntlafatsa phapang le katleho, ho hlokomela likhoebo ho honya le ho ikamahanya le maemo. Joalokaha moemeli ea etellang pele eps Bold eps, re etsa lintho ka tloaelo ho fana ka tharollo e lumellanang le litsi tsa basebetsi ba bareki le merero ea maano.

- Tlhahiso e nepahetseng le lisebelisoa tsa eps Mold

Tokisetso ea kamehla ea liea ea eps e bohlokoa bakeng sa katleho ea tlhahiso le katleho ea nako e telele e sebetsanang le ho phela bophelo bo telele. Linoko tsa khafetsa li bontša ho apara le ho taka tse ka amang ho nepahala ha sehlahisoa sa li-eps tsa ho qetela. Joalokaha moetsi oa Mol ea Hlooho eps, re khothaletsa mokhoa o khotsofatsang oa ho hlokomela bobusi, ho kenyelletsa ho hloekisa, lubrication le likotlo tsa nako le nako. Tlwaelo ena ha e thibele ho lahleheloa ke lapeng empa e etsa mohlala oa boleng bo sa fetoheng betch e 'ngoe le e' ngoe e lumellaneng, ho phahamisa litekanyetso tse phahameng tsa indasteri ea eps. Rea fana ka tšehetso e felletseng ea tlhokomelo ea tlhokomelo ea ho thusa likhoebo ho utloisisa tšebetso ea bona ea tlhahiso.

- Tšusumetso ea taolo ea boleng ho eps Mold Production

Taolo ea boleng ke karolo ea bohlokoa ea eps Mold Mor Ho ea bohlokoa Sena se kenyelletsa liteko tse feletseng le tlhahlobo mohatong o mong le o mong o le mohato ka mong oa tlhahiso, moralo oa pele kopanong ea ho qetela. E le moetsi oa setsebi sa hlobo ea eps, mehato ea boleng ba eona e kenyelletsa nyehelo e matha le liphetoho ho ntlafatsa ts'ebetso ea bohlokoa le ho nepahala ha sehlahisoa ka seng. Ho tiisetsa boleng ba boleng feela empa ho khothaletsa kotsi ea ho e bolokoa lihlahisoa tsa li-eps tsa ho qetela, tse isang khotsofalong ea bareki le ho ts'epahala.

- Lits'ebetso tsa EPS Mold Famud Tradefertice

Ho ntlafatsa mokhoa oa ho fetisetsa mocheso ho eps hlobo e ka lebisa ntlafatsong ea bohlokoa ka lebelo la tlhahiso le ts'ebeliso ea matla. Sena se kenyelletsa ho u thusa moralo oa ho tsamaisa le ho futhumatsa le ho futhumatsa le ho futhumatsa linako tsa potoloho le tlhahiso ea potoloho. Lisebelisoa tse tsoetseng pele le likokotale tse kang Teflon, li bapala ho ntlafatsa ho lokolloa ha lihlahisoa tsa EPS ho tsoa Bold, e ntse e ntlafatsa ts'ebetso e tsoelang pele. Joalokaha moetsi oa Molld Eps, re tsoela pele ho hlahlobisisa tharollo ea mocheso, ho loantša lits'ebetso tsa rona tsa theknoloji ho fana ka ts'ebetso e phahameng ea theknoloji.

- Liphephetso le Tharollo ho EPS Mold Comanization

Ho etsa lintho tse amanang le limaraka tse kang ho netefatsa ho lumellana le lits'ebetso tse teng le ho kopana le litlhokahalo tsa moralo oa moreki. Liphephetso tsena li hloka ho utloisisa ka botlalo ha thepa e fapaneng, bokhoni ba likatiki le tsebo e tsoetseng pele ea mochini o tsoetseng pele. E le moetsi oa EPSoase eps, re rarolla mathata ana ka ho lelekisa boiphihlelo ba rona ba indastera le boiphihlelo. Sehlopha sa rona se sebelisana haufi-ufi le bareki ho tsamaisa litloaelo tsa bona, ho tiisa matla ka lebaka la ho lumellana ho e-na le ho sitisa mekhoa ea tlhahiso.

- Bokamoso ba EPS Mold Ho Etsahala

Tsoelo-pele ea theknoloji le lisebelisoa tsa lisebelisoa li beta bokamoso ba eps Mold Mor Mahlale a hlahang a kang Ai - Moralo o hlophisitsoeng le khatiso ea 3D ho ka fetolela tlhahiso ea boea, ho fana ka maemo a manyane. Ha meece ea tikoloho ea Tikoloho e ntse e tsoela pele ho ama litloaelo, mekhoa e matlafatsang le ntlafatsong ea boitsebiso e tla ba teng. Joaloka pele - Ho Tseba EPSeledr eps Mold Eps, re ntse re le ka pele ho lipatlisiso le nts'etsopele ho fana ka litlhoko tsa ho bulela litlhoko tsa indasteri.

- Ho Utloisisa Tsamaiso ea Liphapa tsa EPS Moldcycle

Ho tsamaisa bophelo ba lifate tsa limmapa ho kenyelletsa moralo oa merero ea mangano ho moralo, ho netefatsa hlobo e 'ngoe le e' ngoe e sebetsa hantle le e tsitsitseng. Hona ho kenyelletsa kemiso ea kamehla ea ho fumana khafetsa, ho lekola ts'ebetso le ho sebelisa mekhoa ea ts'ebetso. Qetellong ea bophelo ba bophelo ba hlobo, ho pheta-pheta kapa ho kenya thepa ea eona ho ka kenya letsoho mererong e tsitsitseng ea ho etsa tlhahiso. E le moetsi oa setsebi sa hlobo eps, re buella maanong a ho qetela a bophelo a bophelo bo matlafatsang a ho phela nako e ngata, le likhoebo tsa tikoloho le tlhahiso ea tlhahiso ea tlhahiso.

Tlhaloso ea setšoantšo

Ha ho na tlhaloso ea setšoantšo bakeng sa sehlahisoa sena