Morekisi oa Lits'ebeletso tsa Mochine oa EPS tse tsoetseng pele

Litekanyetso tsa sehlooho tsa sehlahisoa

| Paramente | Fav1200 | Fav1n00 | Fav1600 | Fav1750 |

|---|---|---|---|---|

| Mold Teversion (mm) | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 |

| Boholo ba sehlahisoa sa max (mm) | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 |

| Stroke (limilimithara) | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 |

| Steam Ho kena (Inch) | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Tšebeliso (KG / Cycle) | 5 ~ 7 | 6 ~ 9 9 | 7 ~ 11 | 8 ~ 12 |

| Khatello (MPA) | 0.5 ~ 0.7 | 0.5 ~ 0.7 | 0.5 ~ 0.7 | 0.5 ~ 0.7 |

Litlhaloso tse tloaelehileng tsa lihlahisoa

| Tšobotsi | TLHOKOMELISO |

|---|---|

| Sebopeho sa mochini | 7 ~ 25mm tšepe, ea matla, ha ho na motsamaisi oa moreki ea hlokahalang. |

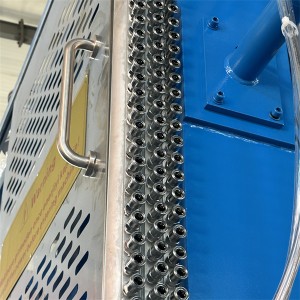

| Ho tlatsa sistimi | Mefuta e meraro: vacuum, e ne e hatelletsoe. 44 masoba a masene. |

| Sistimi ea Steam | Lekala Volve, Jeremane Elec Turve e switch ea Switch Gauge. |

| Sistimi e futhumatsang | Vacuum e otlolohileng e nang le spray ea metsi. |

| Sistimi ea Drainage | Valve e kholo ea serurubele, e hula ka potlako. |

Ts'ebetso ea lihlahisoa tsa sehlahisoa

Mechine ea Comates e kenyelletsa ts'ebetso e makatsang e qalang ka boitokisetso bo botle, e netefatsa li-eps tse hloekileng le tse phatlalalitsoeng bakeng sa ho khomarela boea bo nepahetseng. Mokhahlelo oa kopo o tiisa seqha sa kopo se tsoetseng pele kapa o le bohlokoa bakeng sa bosholu ba ts'ireletso le bo botle. Mohato oa bohlokoa, mohato oa bohlokoa moo koae ea ho tšoarella le ho hanyetsa le ho hanela mabaka. Qetellong, ho ka sebelisoa lits'ebetso tse kang ho qoba kapa ho bokahamile, ho fihlela ponahalo eo e batlang e lebelletse. Mokhoa ona o rarahaneng o tiisa sephetho sa boleng bo phahameng, joalo ka bopaki ba lithuto tse ngata tse qaqileng tsa ho etsa hore mahlale a iphahlahlobang Mahlalelong a Theknoloji le Mahlale a Lintho tsa Boitsebiso.

Maemo a Kopo ea Sehlahisoa

Mechine ea Defatings ke pivotal ho indasteri e fapaneng. Ho ea haheng, ho sebelisoe bakeng sa ho theha li-panels tse kentsoeng le ho aha moo ho tšoarellang le aesthetics e bohlokoa. Ho boloka thepa, li-eps tse koahetsoeng li fana ka tšireletso e phahameng bakeng sa ts'ireletso ea elektroniki le lintho tse lahlehileng. Ho fapanyetsana likopo li atoloha ho pheha khang, ho kenyelletsa le lino tse khabisitsoeng le ho saena, moo ho bonahalang eka lintho tse phelang li hlakile. Patlisiso e matla e totobatsa hore na mechini ena e nolofalletsa ts'ebeliso e hlophisitsoeng, ho fetolela lisebelisoa tse matla tse loketseng lipehelo tse ngata.

Sehlahisoa kamora - Tšebeletso ea thekiso

- Koetliso e felletseng bakeng sa bathipetsing ba ho sebelisa mekhoa le tlhokomelo.

- 24/7 Tšehetso ea tekheniki le thuso ea mathata.

- Waranti mabapi le likarolo tsohle, o netefatsa khotso ea bohlokoa bakeng sa bareki ba rona.

- Lintlafatso khafetsa mabapi le ntlafatso ea software le tsamaisong ea sistimi.

- Ho fumana litšebeletso tsa sebaka sa sebaka bakeng sa ho hlokomela le ho lokisa ha ho hlokahala.

Tsamaiso ea Lihlahisoa

Ho tsamaisa thepa ea rona ea Deprating ho etsoa ka tlhokomelo e kholo, ho sebelisa pakete ea litsietsi le thepa e tšepahalang. Re netefatsa phepelo ea nako e telele le ts'ebetso e bolokehileng, e utloisisa bohlokoa ba lipalangoang tse tšepahalang ka ho lula re tšepahala le ho sebetsa mochini oa rona ho fihla. Sehlopha sa rona sa thepa ea thepa e hokahanya haufi le bareki ho sebetsana le litokomane tsa setso le ho fana ka linako tsa nako.

Melemo ea sehlahisoa

- Ts'ebetso e ikemetseng e fokotsa litšenyehelo tsa basebetsi le ho eketsa katleho.

- E lumellana le e phahameng - boleng ba boleng bo holimo ho tlhahiso e ngata.

- Ho feto-fetoha le maemo likolong tsa koae, ho etsa indastering e fapaneng.

- Ho ferekana le ho hohela lintho tse matlafatsang tsa lihlahisoa tse felisitsoeng.

- Theknoloji ea Provented e tšehelitsoe ke lipatlisiso tse ngata le nts'etsopele.

FAQ ea sehlahisoa

- Tšebeliso ea mantlha ea mochini oa li-eps ke ofe?

Mochine oa rona oa ho roala ops Joaloka mofani ea etellang pele, re netefatsa Top - Theknoloji ea Tier e kopanang le litlhoko tse fapaneng tsa khoebo.

- Mochini o ntlafatsa botšepehi ba lihlahisoa tsa ePes joang?

Likotsi li ile tsa sebetsa ke mochini oa rona oa ho ja lijo tsa rona tse thata, tse eketsang botšepehi bo thata tsa lihlahisoa tsa eps, li li amella ho mamella le mojaro. Ntlafatso ena ke karolo ea bohlokoa ea linyehelo tsa rona e le mofani oa thepa.

- Ke indasteri efe e tsoelang pele ho li-mochine oa Comates?

Mechine ea Coings ea Dep e sebetsa leloko e fapaneng, ho kenyelletsa kaho, ho tsamaisa le ho ba le litšoantšo tse khahlisang. Karolo ea rona ea ho ba morekisi ea tšepahalang e netefatse liindasteri tsena e fumana mechine e ntlafalitsoe bakeng sa lits'ebetso tsa tsona tse khethehileng.

- Na ho na le mefuta e fapaneng ea likolobe tse fumanehang ka mochini?

Ee, mochini oa rona oa ho roala li-coating o ka sebelisa mefuta e fapaneng ea likokotabelo, tse kang samente - thehiloe sa samente -. E thehiloe Polyurethane. Mofuta o mong le o mong o phethahatsa merero e fapaneng, ho tsoa ho ntlafatsa khanyetso ea mollo ho fana ka litefiso tsa botle. Joaloka mofani oa hau, re tataisa hore u khethile takatso e nepahetseng ea litlhoko tsa hau.

- Litlhoko tsa mochini ke eng?

Mechine ea rona e na le litlhokahalo tse fapaneng tsa matla ho latela mohlala. Mohlala, mohlala oa Fav1200 o sebetsa ka 9 kw. Re fana ka litlhaloso tse qaqileng ho netefatsa hore sebaka sa hau se ka boloka litlhoko tsena, li ts'ehetsa ho ba mofani oa kana a tšepahalang.

- Moqapi o netefatsa hore o etsa kopo ea kopo ea koae joang?

Machine oa rona oa ho roala li-eps o sebelisa mekhoa e metle ea ho lokisa le ho laola lihlahisoa tsohle, e le litekanyetso tsa bohlokoa tseo re li etsang ho barekisi.

- Na koetliso e fanoang ka ho reka mochini?

E, koetliso e felletseng e kenyelelitsoe le mochini o mong le o mong oa mochini o reke. Litsebi tsa rona li fana ka tataiso tse sebetsang le tlhokomelo ho netefatsa ts'ebeliso e nepahetseng, ho tšehetsa boitlamo ba rona e le morekisi ea inehetseng.

- Ke lits'ebeletso tsa tlhokomelo e fumanehang - Reka?

Re fana ka chelete e ngata kamora - Tšehetso ea thekiso, ho kenyelletsa le tlhokomelo ea morao-rao, le litlatsetso, li tiisa litlhoko tsa hau tsa EPS.

- Na litharollo tse hlophisitsoeng li fumaneha?

Ehlile. Re fana ka likhetho tsa tloaelo ea ho etsa litlhoko tse ikhethileng, tse bonts'ang li siamisitse le ho inehela ho thepa e etellang pele ea mochini oa EPS.

- Ke mehato efe e nkiloeng ho netefatsa polokeho ea mochini?

Polokeho ke eona ntho e tlang pele. Mechine ea rona e kenyelletsa likarolo tse ngata tsa polokeho, joalo ka ho emisa ho emisa le ho bapala ka tšireletso, ho etsa hore re be le motho ea ikarabellang.

Lihlooho tse chesang tsa sehlahisoa

- Lits'ebetso tsa mochini oa EPS Coating Machine: Tlhatlhobo e tsoang ho morekisi ea etellang pele

Joaloka morekisi ea etellang pele indastering, re sa khaotse ho khaola hape - Mahlale a bohale a kena mechini ea rona ea Comatings. Tsoelo-pele ea morao-rao e bua ka ho kenella le ho nepahala, e lumella likopo tse phahameng tsa ho koahela ka bobeli tse phahameng - boleng - Sehlopha sa rona sa ho hola se sebetsa haufi le litsebi tsa indasteri ho netefatsa mechini ea rona e kopana le litlhoko tsa 'maraka a ntseng li hlahisa' maraka o ntlafalitse le ts'ebetso. Lits'oants'o tsena ha li ntlafatse ts'ebetso ea ts'ebetso feela empa li boetse li kenya letsoho indastering ea ho angoa pele ka ho beha litekanyetso tse ncha ho eps coating souting.

- Tšusumetso ea tikoloho ea mechini ea Demates: pono ea mofani oa thepa

Ho tsitsipana 'moho ho ea bohlokoa le ho ba Motlatsi oa tikoloho, re le motho ea ikarabellang, re le molemo pele Eco - mekhoa e botsoalle ho mechini ea rona ea Demates. Re shebisisa litšila le matla a matla ka boqapi ba mechine e ntlafalitsoeng le matla a motlakase - Mahlahlali a sebetsang. Mechine ea rona e tšehetsa metsi - ho latela mabaka a mosa le tikoloho ea tikoloho, a thusa bareki ho fihlela lipakane tsa bona tse matlafatsang. Boitlamo bona ho litloaelo tse botala bo bontša boinehelo ba rona ho ntho ea boitšoaro bo nang le tekanyo e matlafatsang letsi le 'mele le matla a tikoloho ho pholletsa le lits'ebetso tsa rona.

- Ho khetha morekisi ea nepahetseng bakeng sa li-eps tsa Demates: LITLHAKISO TSA BOPHELO

Ho khetha mofani ea nepahetseng ho bohlokoa bakeng sa likhoebo tse batlang mechini ea koae. Liphihlelo tsa Bohlokoa Tse Tengola Bophahamo ba mahlalehlasisi, kamora - Tšehetso ea thekiso le mekhoa ea tloaelo. Joaloka mofani ea nang le boiphihlelo, re fana ka liphutheloana tse felletseng tsa litšebeletso, li netefatsa hore li-fantisi tse sa feleng li tiisitsoe haholo. Bokhoni ba rona ba ho tsamaisa litloholo tsa litlhokahalo tsa indasteri bo re rehelletsa, ho kenyelletsa ho amana le lipheo tsa tlhahiso ea bareki.

- Bokamoso ba EPS ka Kaho: Likopo tse tsoetseng pele tsa mechini e kopaneng

EPS materials are playing an increasingly significant role in construction, driven by the capabilities of modern coating machines. Joaloka mofani oa thepa, re fana ka mechine ea motlakase, e ntlafatsang methapo ea mafura, e etsang hore litharollo tse tsitsitseng tsa moaho o tsitsitseng. Bokamoso ba li-EPS qalong bo khanya, 'me ka ho tsoella ha mahlale a hooa a hola likopo tsa eona. Mechine ea rona e ea pele ho thuto ena ea ho iphetola ha lintho tsena, ho tšehetsa boiteko ba bareki ba ho kenyelletsa lisebelisoa tse tsoetseng pele mererong ea bona.

- Ho utloisisa maemo a ho qetela: Tlhaloso e tsoang phihlelong ea morekisi

Melao ea indasteri ea li-eps cumating ke ea bohlokoa bakeng sa ho netefatsa boleng le ho latela. E le morekisi ea nang le tsebo, re thusa bareki ho tsamaisa litekanyetso tsena, re fana ka mechini e kopanang kapa e feta ea li-benchmarks tsa indasteri. Boitšoaro ba rona ho litlhoko le mekhoa e metle ka ho fetisisa e tiisa hore lihlahisoa tsa bareki ba rona li latela mekhoa e mengata ea polokeho le ts'ebetso ea ts'ebetso. Kutloisiso ena e bohlokoa bakeng sa bareki ha ba ntse ba boloka litekanyetso tsa bona tse ngata ha ba ntse ba nyenyefatsa nakong ea kholo ea sehlahisoa.

- Ho holisa roi le mechini ea Deprains: maano a tsoang ho mofani ea etellang pele

Ho tsetela ho li-eps coe in deines ho ka hlahisa ho khutla haholo ha e tsamaisoa hantle. Joaloka mofani oa thepa, re eletsa bareki maano a ho eketsa katleho le ho fokotsa litšenyehelo tsa tlhahiso - Theging theknoloji bakeng sa ts'ebetso e nepahetseng. Mechine ea rona e etselitsoe ho ts'ehetsa ho phahame haholo - tlhahiso e bophahamo ha u ntse u nyenyefatsa litšila le nako ea phomolo. Ka ho kenya mekhoa e metle ka ts'ebetso ea mochini le tlhokomelo, bareki ba ka fihlela roi e kholo, ba rua molemo tlhahisong e matla mme e senyehileng ea ho fokotsa litšenyehelo.

- Ho hlahloba tloaelo ho EPS Coating Fioutions: mokhoa oa mofani oa thepa

Ho etsa tloaelo ke sekhutlo sa sejoale-joale, mme e le mofani oa thepa, re hatisa maikutlo a eps ea ho koahela litlhoko tsa marang-rang ho kopana le litlhoko tse fapaneng tsa indasteri. Hore na litlhahiso tse ikhethang tsa ho khotsofatsa lihlahisoa tse ikhethang tsa sehlahisoa kapa ho kenyelletsa thepa ea rona e ikhethang, likhetho tsa rona tsa tloaelo li thusa bareki ho ntlafatsa mekhoa ea bona ea tlhahiso. Tsela eo re tšoarang ka eona e tiisa hore mochini o mong le o mong o tsamaisana le lipheo tsa maqiti a bareki, a fana ka maemo le ho ikamahanya le maemo 'marakeng o fetolang ka potlako.

- Karolo ea Autorition ho Mechine ea EPS ea EPS: mofani oa Vierfor

Boikhaolo bo fetoloa sebopeho sa eps ea ho koahela, ho fana ka melemo e mengata joalo ka katleho e eketsehileng, e sa tsitsang, e fokotsang litšenyehelo. Joaloka mofani oa thepa, re kopantse theknoloji ea Auto ea pele ho metjeko ea rona, e ntlafatsa ts'ebetso le phoso ea ho fokotsa phoso. Phetoho ena e lumella bahlahisi ho feta tlhahiso ha ba ntse ba boloka maemo a phahameng a le boima ba ho hloka lihlahisoa tsa likhohola ho indasteri e se fapaneng. Boikhatho ha se mokhoa feela empa phetoho ea mantlha ea tlhahiso, 'me mechine ea rona e etselitsoe ho tšehetsa thuto ena ea ho iphetola ha lintho.

- Ho bapisa Meetso ea mochini oa eps: malebela a setsebi ho mofani oa thepa

Ho khetha mofuta oa mochini o nepahetseng oa ho koahela ops o ka fokola, o fuoa mefuta e fapaneng ea likhetho tse fumanehang. Joaloka mofani oa nang le boiphihlelo, re tataisa bareki ka ts'ebetso ea khetho, e leng ho bapisa mefuta e mengata, likarolo le lits'ebeliso tse itseng tsa boikitlaetso. Ho utloisisa linate ka 'ngoe ho tiisa hore bareki ba khetha lisebelisoa tse lumellanang hantle le lipheo tsa bona tse sebetsang hantle le lipheo tsa tlhahiso. Litlhahlobo tse qaqileng tse qaqileng li fana ka leseli la bohlokoa, u thusa bareki ho etsa liqeto tse boletsoeng tse ntlafatsang chelete ea bona ea tlhahiso.

- 'Maraka oa Lefatše oa EPS bakeng sa Mechini e Kopitseng: Tlhahlobo ea morekisi

Mearaka ea Lefatše oa EPS ea Defaine e ntse e hola ka potlako, e khannoa ke chelete ea ho eketseha ha motho a ka ameha, ho tsamaisa le indasteri e meng. Joaloka mofani oa mookameli, re bonahatsa maemo a joalo joalo ka ha ho tsotelehe botsitso ba matla le maemo a matla le a tsoetseng pele a matlafatsang tlhahiso le sehlahisoa sa sehlahisoa. Mechine ea rona e etselitsoe ho kopanya le matla ana a mrose a 'marakeng, ho thusa bareki ka menyetla ea ho hlaha. Ho utloisisa naha ea lefatše ka bophara ho re fa likeletso tsa bohlale le ho seha - Litharollo Tse Tlisang mathata a Lehae la Liindasteri.

Tlhaloso ea setšoantšo

Ha ho na tlhaloso ea setšoantšo bakeng sa sehlahisoa sena