Phahameng - Ts'ebetso e chesang e chesang e chesang e chesang e chesang e chesang e nang le terata ea foam custter - Polystyrene block molding molding

Lintlha tsa sehlahisoa

Polystyrene By bolding moldding ka vacuum ke mochini o sebetsang oa EPS ho etsa li-block. Li-block tsa EPS li ka khaoloa ho lishiti bakeng sa ho panya ha ntlo kapa ho paka. Lihlahisoa tse tummeng tse entsoeng ka lishiti tsa EPS ke li-eps tsa sandwich

Polystyrene By Bolding Morekisi oa polystyrene By e ka hlahisa mabone a bongata bo phahameng, ho sebetsa potoloho e potlakileng, le lithibelo tsohle li otlolohile ebile li le mongobo o tlase oa metsi. Mochine o ka etsa hore ho be le li-block tse tlase tse nang le boleng bo botle. E ka etsa letsoalo le phahameng ho 40g / l le mafura a tlase ka 4g / l.

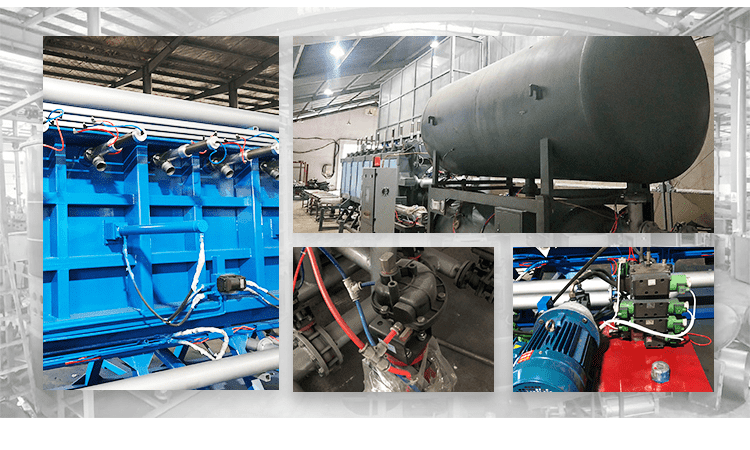

Polystyrene block moldding mofding ka sekheo se felletseng ka 'mele oa mochini oa mochini, lebokose la taolo, sistimi ea vacuum, e boima.

Polystyrene By Molding Mokolling ka melemo ea Vapuum:

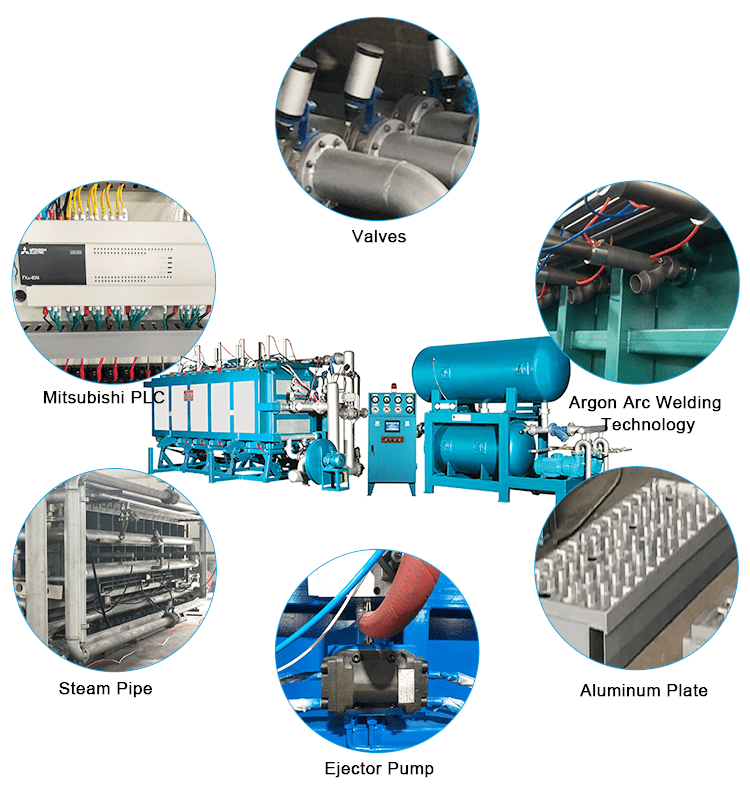

1.machine e entsoe ka bolelele ba lisekoere - matla a matla le lipolanete tse teteaneng;

Mmune o sebelisa 5mm e teteaneng ea li-aluminium steam e nang le koae ea Tefn. Ka tlas'a aluminium polete, tšehetso e kholo ea mekhahlelo e ngata haholo e behiloe ho qoba mokhoa oa aluminium platate o le boima tlasa khatello e kholo. Aluminium plates'T Fetola Foromo kamora lilemo tse leshome u sebetsa;

3.machine'SHO kaofela li se li le ka kalafo ea mocheso ho lokolla khatello ea maikutlo, kahoo ho ke ke ha e-ba teng ka tlas'a mocheso o phahameng;

4.machine e nang le mela e meng e mouoane ho netefatsa ho utsoa esita le lithibela, kahoo thibela lerata e molemo;

Litopa tsa 2 tsamachine li na le sistimi e metle ea lithibelo kahoo li-block li omme haholo 'me li ka khaoloa ka nako e khutšoanyane;

Mochine oa mochini o phatloha ka mafome, oa fafatsa, ebe o etsa anti -

7.mashine sebelisa sistimi e bohlale le ts'ebetso e benyang, e bonts'a khalefo e ntle bakeng sa letsoalo le phahameng le letsoalo le tlase;

8. Sistimi e sebetsang ea ho tlatsa le ho feta e tiisa mochini ho sebetsa ka potlako, mothapo o mong le o mong oa 4 ~ 8 metsotso;

9. Aejection e laoloa ke pompo ea hydraulic, kahoo ejector tsohle li sutumetsa ebe li khutla ka lebelo le le leng;

10. Metsoako e felletseng e sebelisitsoeng mochini e na le lihlahisoa tse tsoang kantle ho naha.

Li-paramente tsa sehlooho tsa tekheniki

Ntho | Yuniti | PB2000v | Pb3000v | PB4000V | PB6000v | |

Boholo ba Mold Cavity | mm | 2040 * 1240 * 1030 | 3060 * 1240 * 1030 | 4080 * 1240 * 1030 | 6100 * 1240 * 1030 | |

Thibelo ea boholo | mm | 2000 * 1200 * 1000 | 3000 * 1200 * 1000 | 4000 * 1200 * 1000 | 6000 * 1200 * 1000 | |

Steam | Ho kena | Inch | 2 '' (DN50) | 2 '' (DN50) | 6 '' (DN150) | 6 '' (DN150) |

Tšebeliso | KG / Cycle | 25 ~ 45 | 45 ~ 65 | 60 ~ 85 | 95 ~ 120 | |

Khatello | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Moea o hatelletsoeng | Ho kena | Inch | 1.5 '' (DN40) | 1.5 '' (DN40) | 2 '' (DN50) | 2 '' (DN50) |

Tšebeliso | m³ / potoloho | 1.5 ~ 2 | 1.5 ~ 2.5 | 1.8 ~ 2.5 | 2 ~ 3 | |

Khatello | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

Vacuum e futhumatsang metsi | Ho kena | Inch | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) | 1.5 '' (DN40) |

Tšebeliso | m³ / potoloho | 0.4 | 0.6 | 0.8 | 1 | |

Khatello | Mpa | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | 0.2 ~ 0.4 | |

Drainage | Vacuum drain | Inch | 4 '' (DN100) | 5 '' (DN125) | 5 '' (DN125) | 6 '' (DN150) |

Tlase steam vent | Inch | 4 '' (DN100) | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | |

Moea oa moea oa moea | Inch | 4 '' (DN100) | 4 '' (DN100) | 6 '' (DN150) | 6 '' (DN150) | |

Boxity 15kg / M³ | Metsotso / potoloho | 4 | 5 | 7 | 8 | |

Hokela mojaro / matla | Kw | 19.75 | 23.75 | 24,5 | 32.25 | |

Boholo ba bongata (L * h * w) | mm | 5700 * 4000 * 2800 | 7200 * 4500 * 3000 | 11000 * 4500 * 3000 | 12600 * 4500 * 3100 | |

Boima | Kg | 5000 | 6500 | 10000 | 14000 | |

Nyeoe

Video e amanang le

Our technical team is committed to supporting you in mastering the functionality of the Electric Hot Wire Foam Cutter. We provide comprehensive training and post-purchase support to assist you in harnessing the full potential of this versatile machine. Invest in the future of EPS block moulding with the Electric Hot Wire Foam Cutter from Dongshen, a machine that embodies innovation, efficiency, and performance like none other in the market. Revolutionize your EPS manufacturing process with the advanced technology of our Polystyrene Block Moulding Machine. Experience the Dongshen difference today.