Mochine o tsoetseng pele StyroFam o qhibilihang bakeng sa ho phahama ho phahameng - Bokhoni ba lebokose

Lintlha tsa sehlahisoa

Mochini oa bofokoli ba styrofeta o nang le katleho e phahameng ea lebokose e nang le sistimi e lekaneng ea chicuum, sistimi ea hydraulic e potlakileng le tsamaiso e potlakileng. Bakeng sa sehlahisoa se le seng, nako ea potoloho mochini oa mofuta oa e 25% e khuts'oane ho feta ka mochini o tloaelehileng, 'me tšebeliso ea matla ke 25% e tlase.

Mochini oa bofokoli ba styrofeta o fefolang ka lebokoseng la lebokose le phethelang le PLC, Screen skrini, sistimi e sebetsang, lebokoseng la motlakase

Likarolo tsa sehlooho

Liplate tsa mochini li entsoe ka lipolanete tsa tšepe tsa tšepe kahoo ho tšoarella hole;

Mochini o na le tsamaiso e sebetsang ea chicuum, tanka ea vacuum le Tankraner Tank e arohaneng;

Mochini o sebelisa sistimi e potlakileng ea hydraulic, boloka nako e koalang le ho bula nako.

Mekhoa e fapaneng ea ho tlatsa e fumaneha ho qoba ho tlatsa bothata lihlahisoa tse khethehileng;

Mochini o sebelisa sistimi ea kholo ea lipeipi, e lumella khatello e tlase ea ho beoa. 3 ~ 4bar Steam e ka sebetsa mochini;

Khatello ea mochini le ho kenella ha ho kenella ho laoloa li laoloa ke khatello ea maikutlo ea bohlale le khatello ea khatello ea taolo ea lesika;

Metsoako e sebelisitsoeng mochini e na le lihlahisoa tse kentsoeng ke thepa e hlophisitsoeng haholo, e leng phepelo e tlase;

Mochini o nang le maoto a phahamisang, kahoo moreki o hloka feela ho etsa sethala se bonolo sa ho sebetsa ho basebetsi.

Li-paramente tsa sehlooho tsa tekheniki

| Ntho | Yuniti | Fav1200e | Fav1400e | Fav1600e | Fav1750e | |

| Boholo ba Mold | mm | 1200 * 1000 | 1400 * 1200 | 1600 * 1350 | 1750 * 1450 | |

| Boholo ba sehlahisoa sa Max | mm | 1000 * 800 * 400 | 1200 * 1000 * 400 | 1400 * 1150 * 400 | 1550 * 1250 * 400 | |

| Stroke | mm | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | 150 ~ 1500 | |

| Steam | Ho kena | Inch | 3 '' (DN80) | 4 '' (DN100) | 4 '' (DN100) | 4 '' (DN100) |

| Tšebeliso | KG / Cycle | 4 ~ 7 | 5 ~ 9 | 6 ~ 10 | 6 ~ 11 11 | |

| Khatello | Mpa | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | 0.4 ~ 0.6 | |

| Metsi a futhumatsang | Ho kena | Inch | 2.5 '' (DN65) | 3 '' (DN80) | 3 '' (DN80) | 3 '' (DN80) |

| Tšebeliso | KG / Cycle | 25 ~ 80 | 30 ~ 90 | 35 ~ 100 | 35 ~ 100 | |

| Khatello | Mpa | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | 0.3 ~ 0.5 | |

| Moea o hatelletsoeng | Ho kena ha khatello e tlase | Inch | 2 '' (DN50) | 2.5 '' (DN65) | 2.5 '' (DN65) | 2.5 '' (DN65) |

| Khatello e tlase | Mpa | 0.4 | 0.4 | 0.4 | 0.4 | |

| Ho kena ha khatello e phahameng | Inch | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | 1 '' (DN25) | |

| Khatello e phahameng | Mpa | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | 0.6 ~ 0.8 | |

| Tšebeliso | m³ / potoloho | 1.5 | 1.8 | 1.9 | 2 | |

| Drainage | Inch | 5 '' (DN125) | 6 '' (DN150) | 6 '' (DN150) | 6 '' (DN150) | |

| Boxicop15kg / M³ | S | 60 ~ 110 | 60 ~ 120 | 60 ~ 120 | 60 ~ 120 | |

| Hokela mojaro / matla | Kw | 9 | 12.5 | 14.5 | 16.5 | |

| Boholo ba kakaretso (l * w * h) | mm | 4700 * 2000 * 4660 | 4700 * 2250 * 4660 | 4800 * 2530 * 4690 | 5080 * 2880 * 4790 | |

| Boima | Kg | 5500 | 6000 | 6500 | 7000 | |

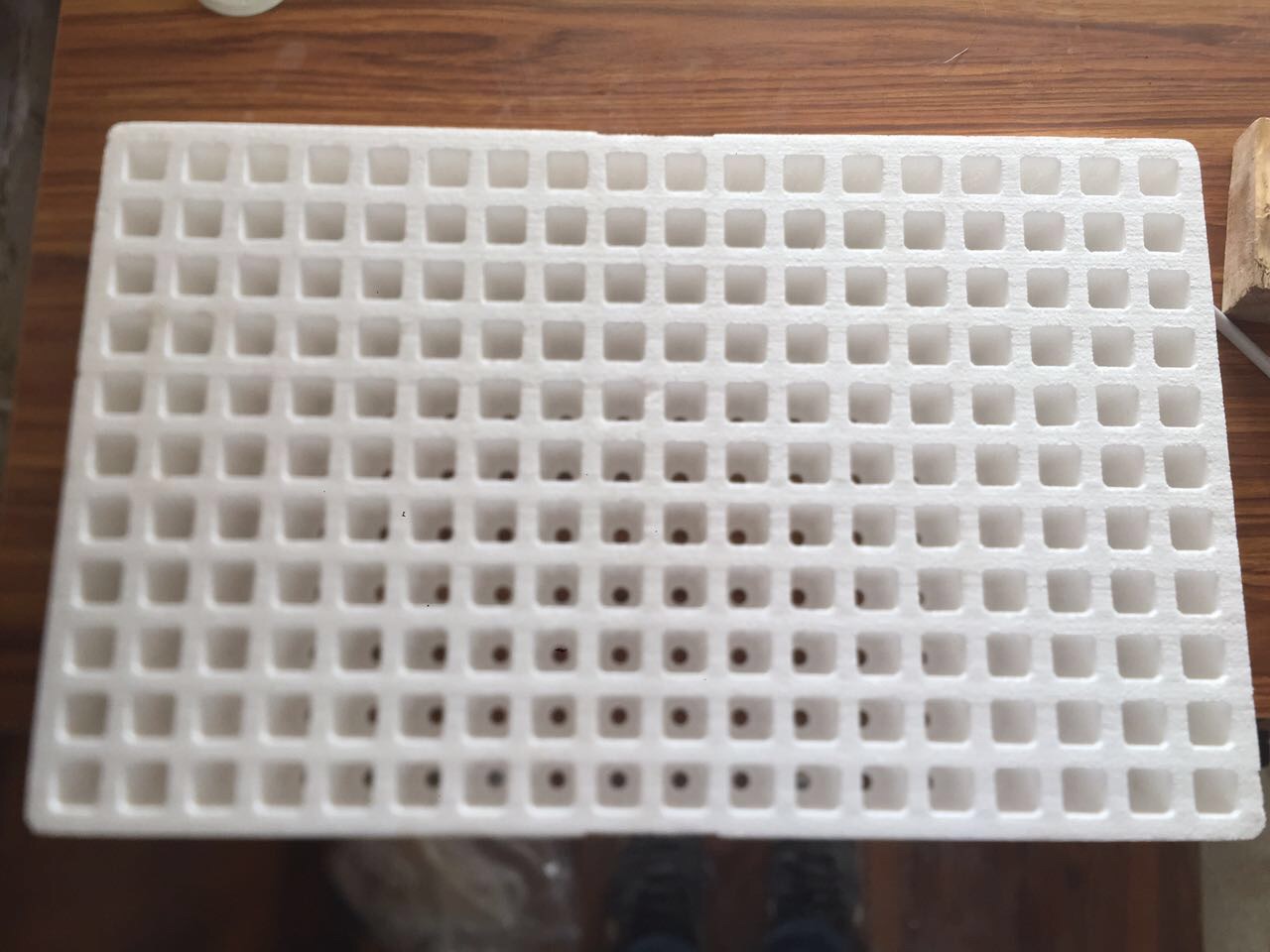

Nyeoe

Video e amanang le

The machine's fast hydraulic system enables seamless operation, reducing manual effort while augmenting productivity. Further, its quick drainage system ensures that the machine maintains its efficiency levels, ultimately improving the overall production rate. By integrating the Styrofoam Melting Machine into your manufacturing line, you can leverage the benefits of a high-performance, energy-efficient and cost-effective solution for your Styrofoam moulding needs. At Dongshen, we understand the importance of efficiency and reliability in manufacturing processes. Our Styrofoam Melting Machine offers you a solution that combines these essentials, empowering your business to deliver superior quality while enhancing production efficiency.